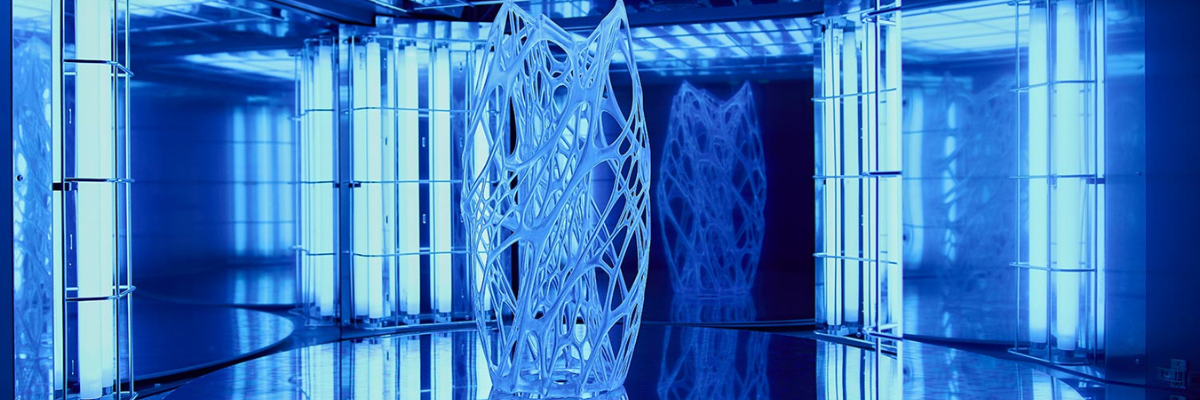

3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Fill up the form below and we will send you the data sheet by e-mail.

Fill up the form below and we will send you the data sheet by e-mail.

Fill up the form below and we will send you the data sheet by e-mail.

Fill up the form below and we will send you the data sheet by e-mail.

The conventional process of ordering custom-made earplugs comes with certain limitations that can harm the user, extend production timelines, and increase the cost and delivery time of custom-made earplugs. A study conducted across the otolaryngology department showed that 14.7% experienced secondary injuries caused by the physical ear impression process. In some cases, the physical impression process left residual material in the ear canal leading to infection or injury. The production timelines extend from three to eight weeks, leading to an extended product delivery date.

Fill up the form below and we will send you the data sheet by e-mail.

There were a lot of issues with the printers that the Orthodontic Lab Brys-Callewaert had before, like parts that fell off from the Formlabs and the closed structure of the different resin possibilities that made developing new products really expensive. The Stratasys® printers required really expensive resin and were a big cost in maintenance and support. Besides that, the Lab had to scale up the production of parts, which was impossible with a printer that needed 10 hours for one build job.

Fill up the form below and we will send you the data sheet by e-mail.

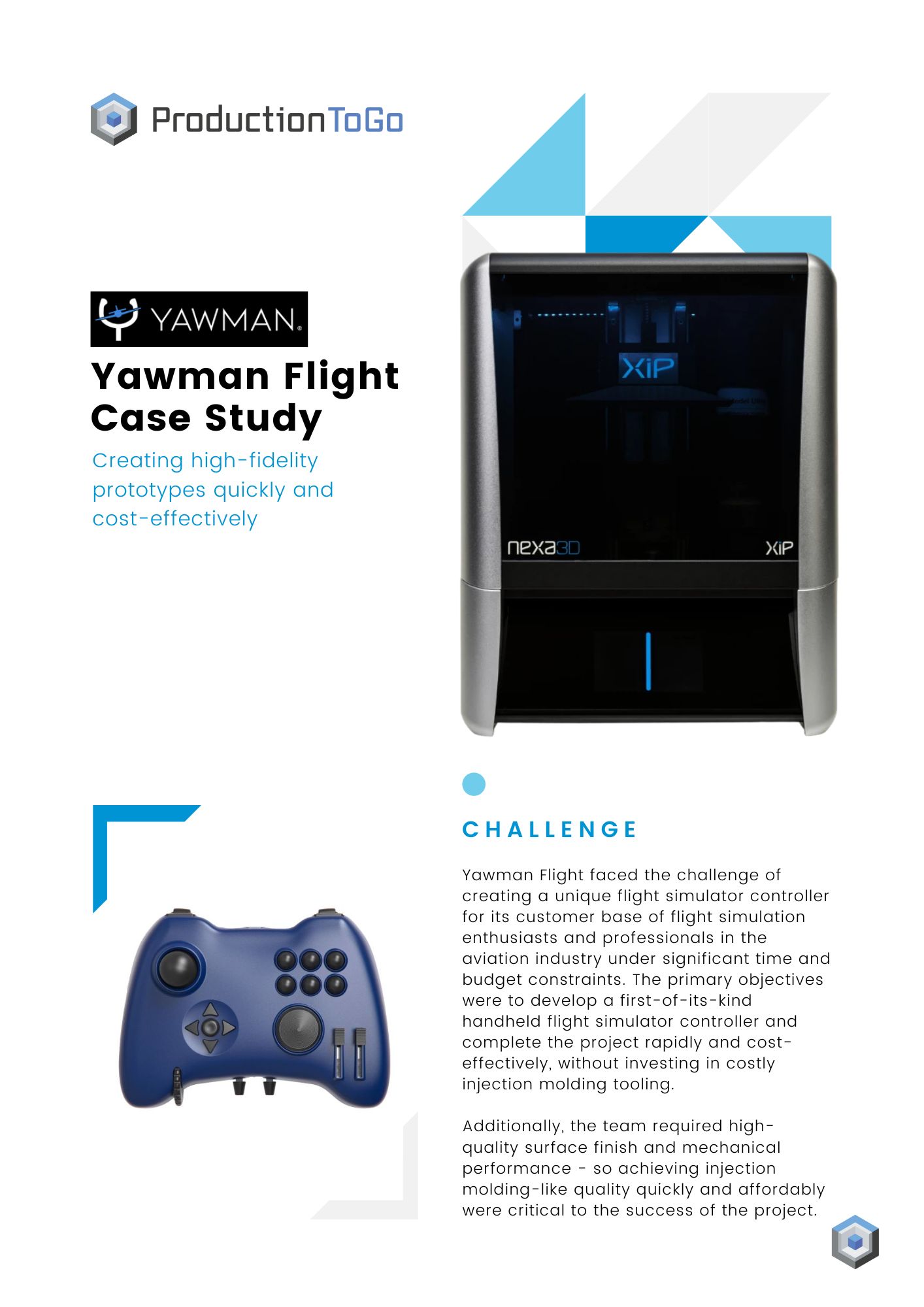

Yawman Flight faced the challenge of creating a unique flight simulator controller for its customer base of flight simulation enthusiasts and professionals in the aviation industry under significant time and budget constraints. The primary objectives were to develop a first-of-its-kind handheld flight simulator controller and complete the project rapidly and cost-effectively, without investing in costly injection molding tooling. Additionally, the team required high-quality surface finish and mechanical performance – so achieving injection molding-like quality quickly and affordably were critical to the success of the project.

Fill up the form below and we will send you the data sheet by e-mail.

Founded in 1952, Inovan GmbH & Co. KG has grown over the decades from a small plant in Birkenfeld to a globally active company with several locations in Germany, China and the Czech Republic. Inovan supplies various branches of industry, from the automotive and electrical industries to the ITC industry, with complex electromechanical components, contact materials and mechanical connecting elements. One of the most important processes within Inovan's production is reel-to-reel electroplating.

Fill up the form below and we will send you the data sheet by e-mail.

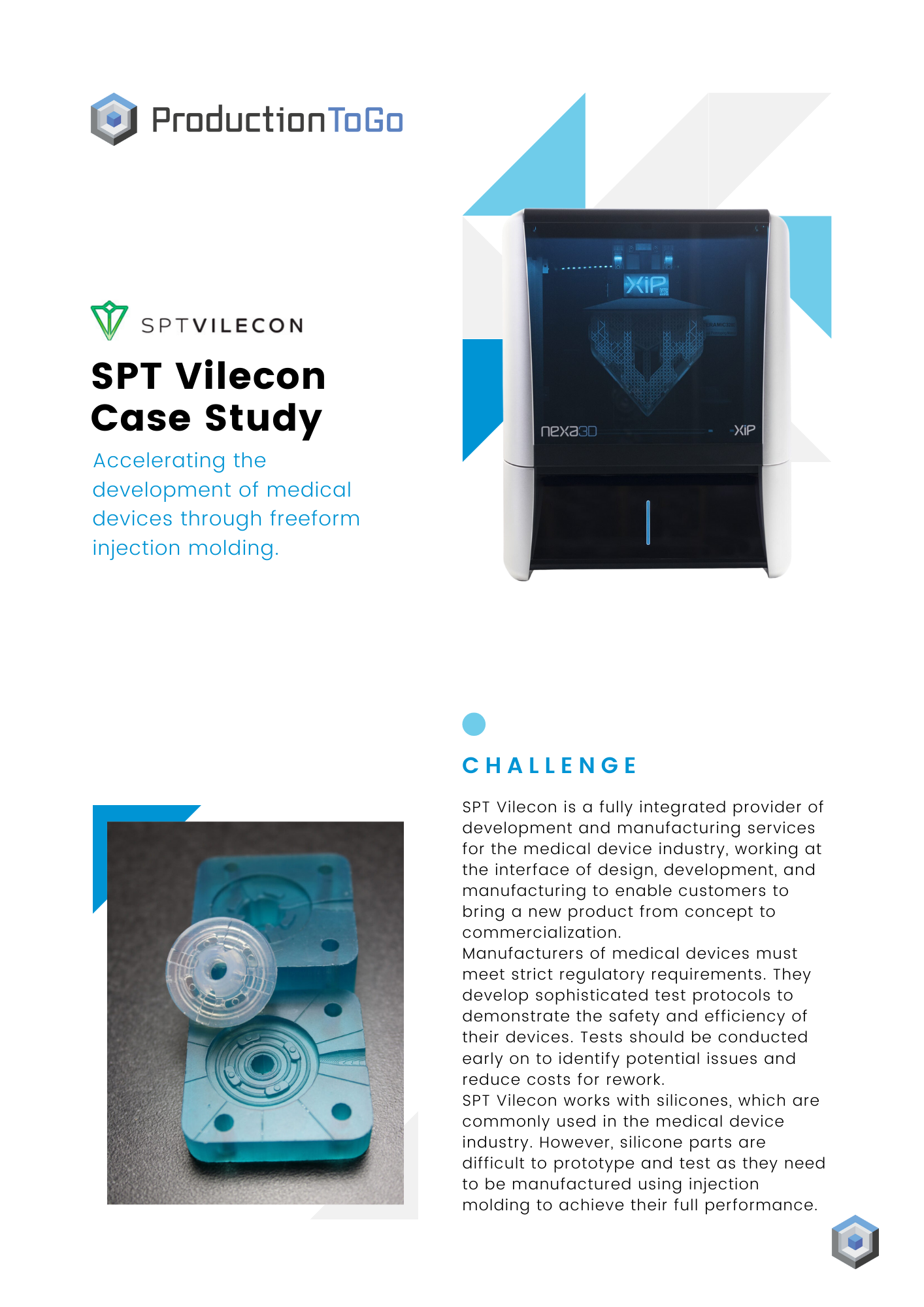

SPT Vilecon is a fully integrated provider of development and manufacturing services for the medical device industry, working at the interface of design, development, and manufacturing to enable customers to bring a new product from concept to commercialization. Manufacturers of medical devices must meet strict regulatory requirements. They develop sophisticated test protocols to demonstrate the safety and efficiency of their devices. Tests should be conducted early on to identify potential issues and reduce costs for rework. SPT Vilecon works with silicones, which are commonly used in the medical device industry. However, silicone parts are difficult to prototype and test as they need to be manufactured using injection molding to achieve their full performance.

Fill up the form below and we will send you the data sheet by e-mail.

Fraunhofer IFAM – an institute in the renowned Fraunhofer Society – is a recognized leader in the field of Metal Injection Molding (MIM), and is serving companies in the aerospace, energy, maritime and other demanding industries. In metal injection molding (MIM), metal powder is mixed with a plastic binder to create a feedstock that is then injected into a metal mold. The abrasive nature of the feedstock places high demand on the quality of the tooling, and the complexity of the MIM process typically results in the need for multiple iterations. Fraunhofer wanted to offer companies a path to quickly and cost-effectively test new concepts and turned to Nexa3D® and Freeform Injection Molding to provide a solution.

Fill up the form below and we will send you the data sheet by e-mail.

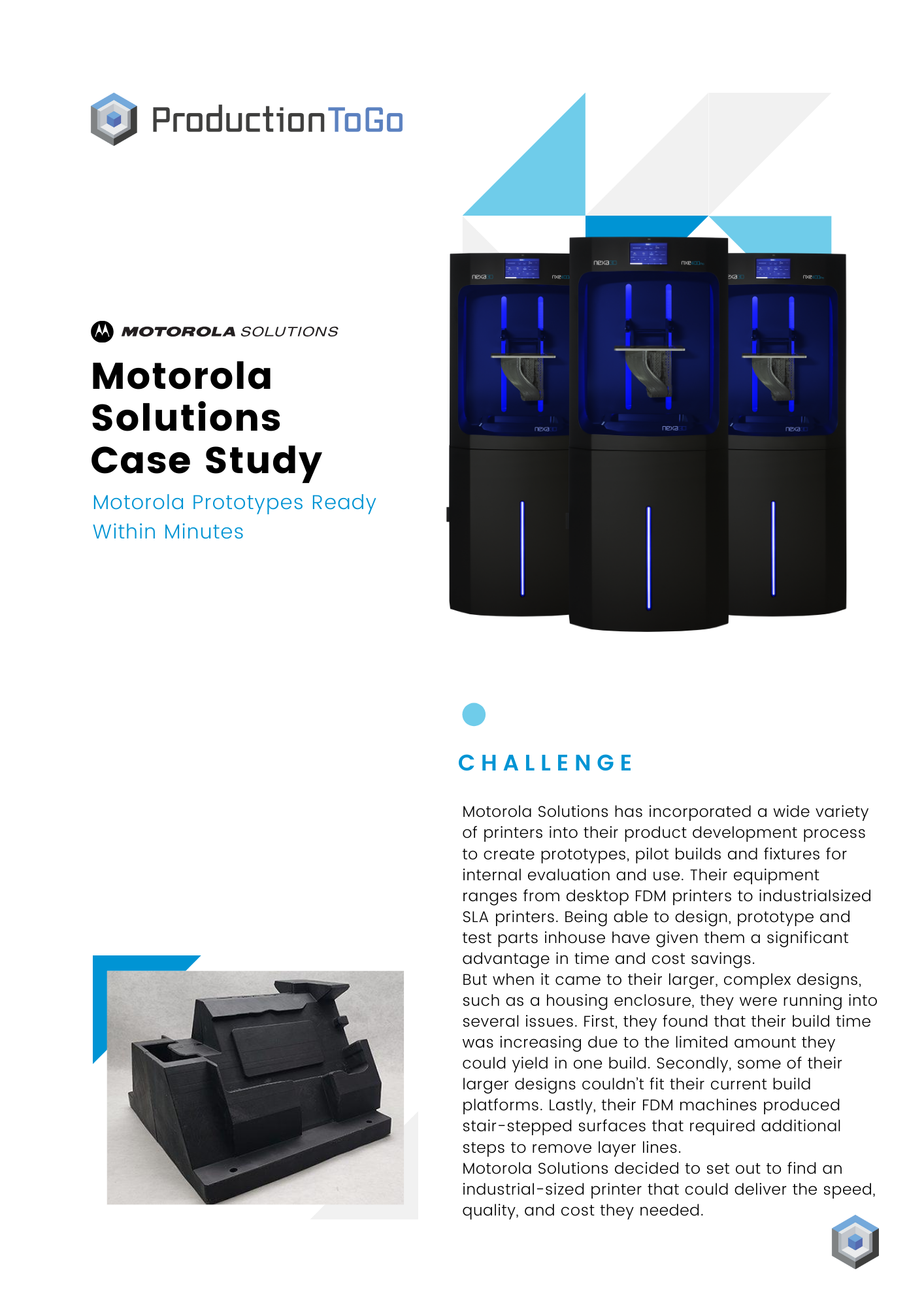

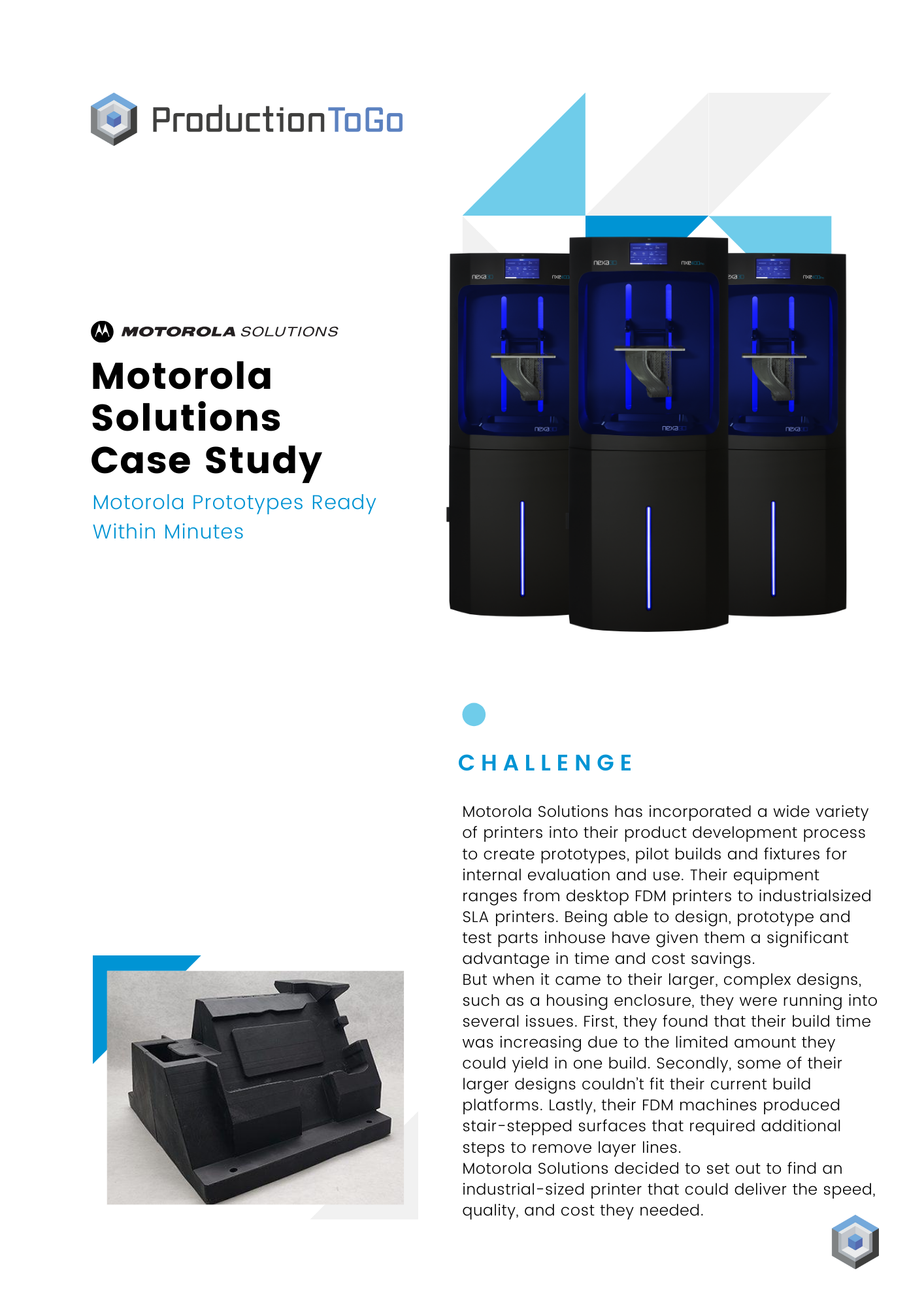

Motorola Solutions has incorporated a wide variety of printers into their product development process to create prototypes, pilot builds and fixtures for internal evaluation and use. Their equipment ranges from desktop FDM printers to industrialsized SLA printers. Being able to design, prototype and test parts inhouse have given them a significant advantage in time and cost savings. But when it came to their larger, complex designs, such as a housing enclosure, they were running into several issues. First, they found that their build time was increasing due to the limited amount they could yield in one build. Secondly, some of their larger designs couldn’t fit their current build platforms. Lastly, their FDM machines produced stair-stepped surfaces that required additional steps to remove layer lines. Motorola Solutions decided to set out to find an industrial-sized printer that could deliver the speed, quality, and cost they needed.

Fill up the form below and we will send you the data sheet by e-mail.

PAKT3D works in partnership with its customers to provide streamlined and efficient manufacturing, design and engineering AM processes. It gives its customers independent advice based on their needs using its extensive sector knowledge. Typical challenges PAKT3D’s customers suffer include long lead times, low quality and costly processes. These are common in engineering, design and manufacturing firms when producing components, mold tools, tooling and prototypes. In addition, many businesses are under time pressure and require a combination of high-speed manufacturing and design agility for their business to remain competitive. These challenges have triggered companies to look at new methods of manufacturing, such as 3D printing, as a solution.

Fill up the form below and we will send you the data sheet by e-mail.

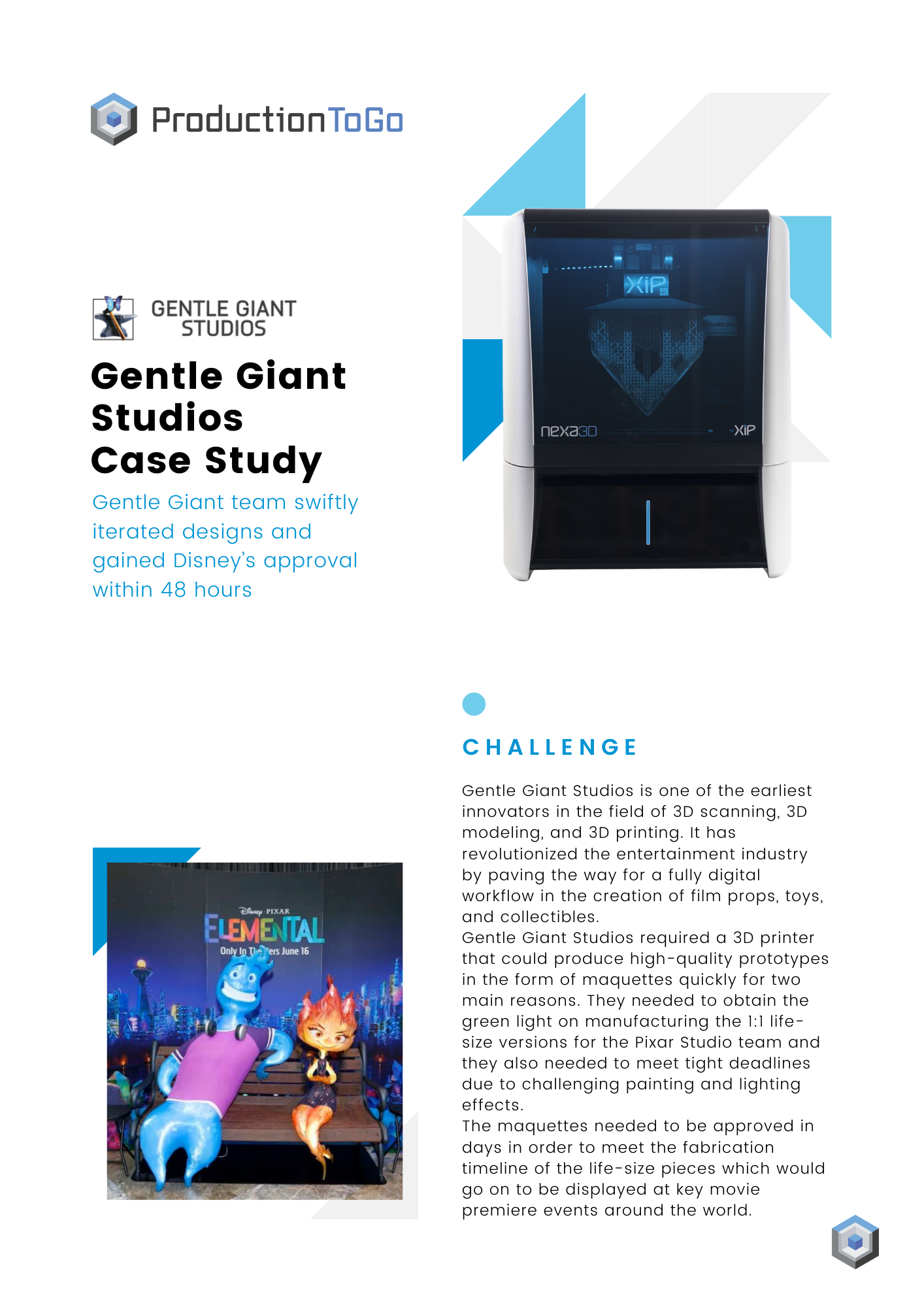

Gentle Giant Studios is one of the earliest innovators in the field of 3D scanning, 3D modeling, and 3D printing. It has revolutionized the entertainment industry by paving the way for a fully digital workflow in the creation of film props, toys, and collectibles. Gentle Giant Studios required a 3D printer that could produce high-quality prototypes in the form of maquettes quickly for two main reasons. They needed to obtain the green light on manufacturing the 1:1 life-size versions for the Pixar Studio team and they also needed to meet tight deadlines due to challenging painting and lighting effects. The maquettes needed to be approved in days in order to meet the fabrication timeline of the life-size pieces which would go on to be displayed at key movie premiere events around the world.

Fill up the form below and we will send you the data sheet by e-mail.

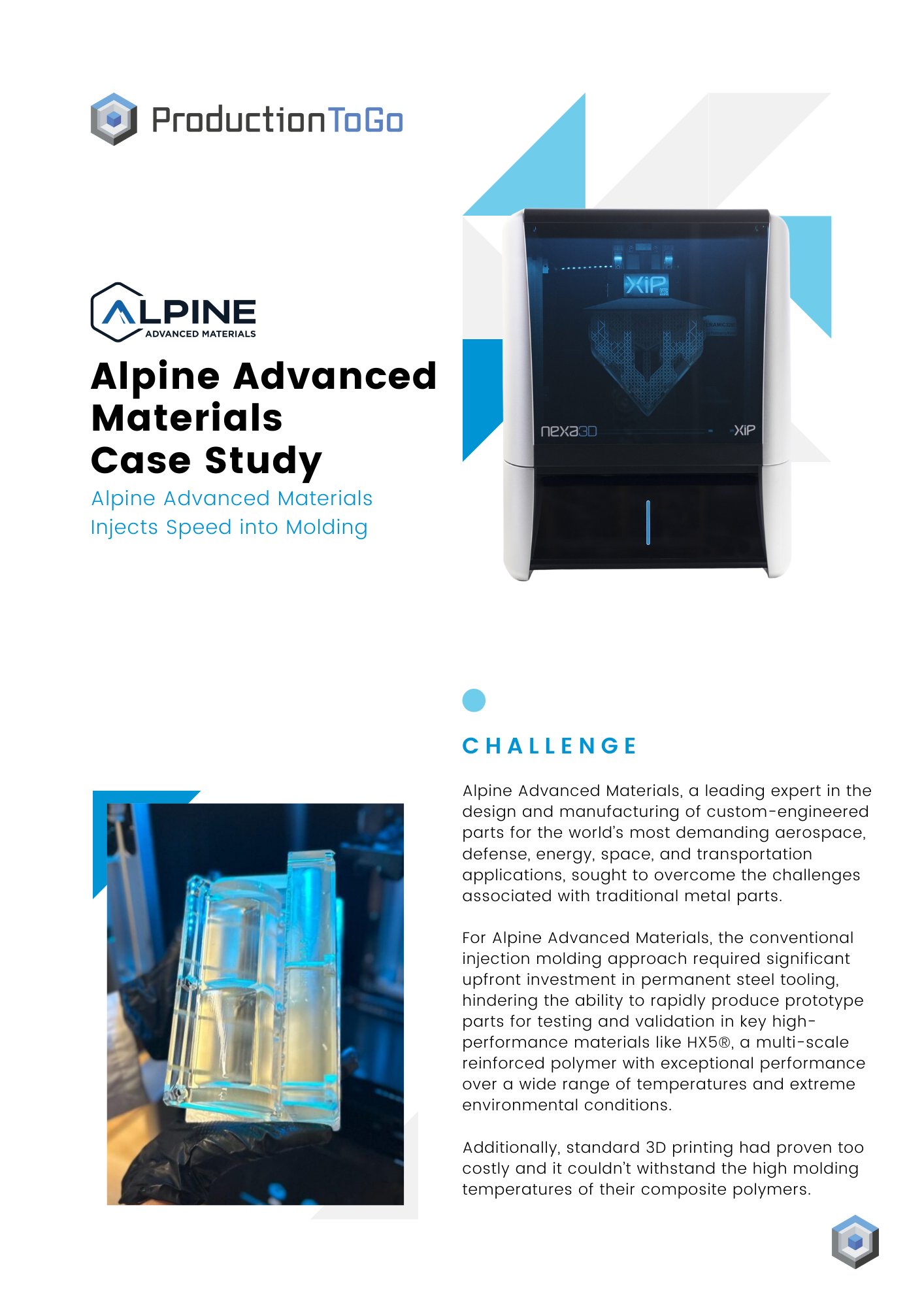

Alpine Advanced Materials, a leading expert in the design and manufacturing of custom-engineered parts for the world’s most demanding aerospace, defense, energy, space, and transportation applications, sought to overcome the challenges associated with traditional metal parts. For Alpine Advanced Materials, the conventional injection molding approach required significant upfront investment in permanent steel tooling, hindering the ability to rapidly produce prototype parts for testing and validation in key high-performance materials like HX5®, a multi-scale reinforced polymer with exceptional performance over a wide range of temperatures and extreme environmental conditions. Additionally, standard 3D printing had proven too costly and it couldn’t withstand the high molding temperatures of their composite polymers.

Fill up the form below and we will send you the data sheet by e-mail.

While the majority of 3D printers at MTB3D are filament-based, they have also implemented a small and agile fleet of resin systems that they can use when quality needs to be on point.. In late 2022, they began exploring the market for a suitable upgrade that would not only provide the highest quality parts, but also with a larger build volume and that would allow them to easily print with 3rd-party resins. “My boss Ewoud was looking for a 3D printer that we could use with third-party resins because our main filament supplier recently started supplying resin as well. We wanted something more than a small, cute little resin 3D printer that you see everywhere – we wanted a bit more size,” says Arturo Gala Sagrera, 3D Print Specialist at MTB3D.

Fill up the form below and we will send you the data sheet by e-mail.

While additive manufacturing has been at the center of ART’s business since the beginning, today about half of the end products they produce are not 3D printed, but cast urethane. Casting in urethane has allowed ART to produce low cost plastic parts with a quick turnaround. It is a very hands on process that takes a minimum of 24 hours per mold, requires a significant amount of labor, and the end result is a mold capable of up to 25 parts depending on the material being cast. That said, the effort appears worthwhile based on the high demand from their customers. “Our cast urethane is about 50% of our business right now and we’re almost maxed out,” says Bruce LeMaster, Founder and Vice President of ART. In addition to urethane, ART follows a similar 24 hour process for silicone molding. With such high demand, LeMaster and the team at ART were all but maxed out with a very real cap on the volume of projects they could take on.

Fill up the form below and we will send you the data sheet by e-mail.

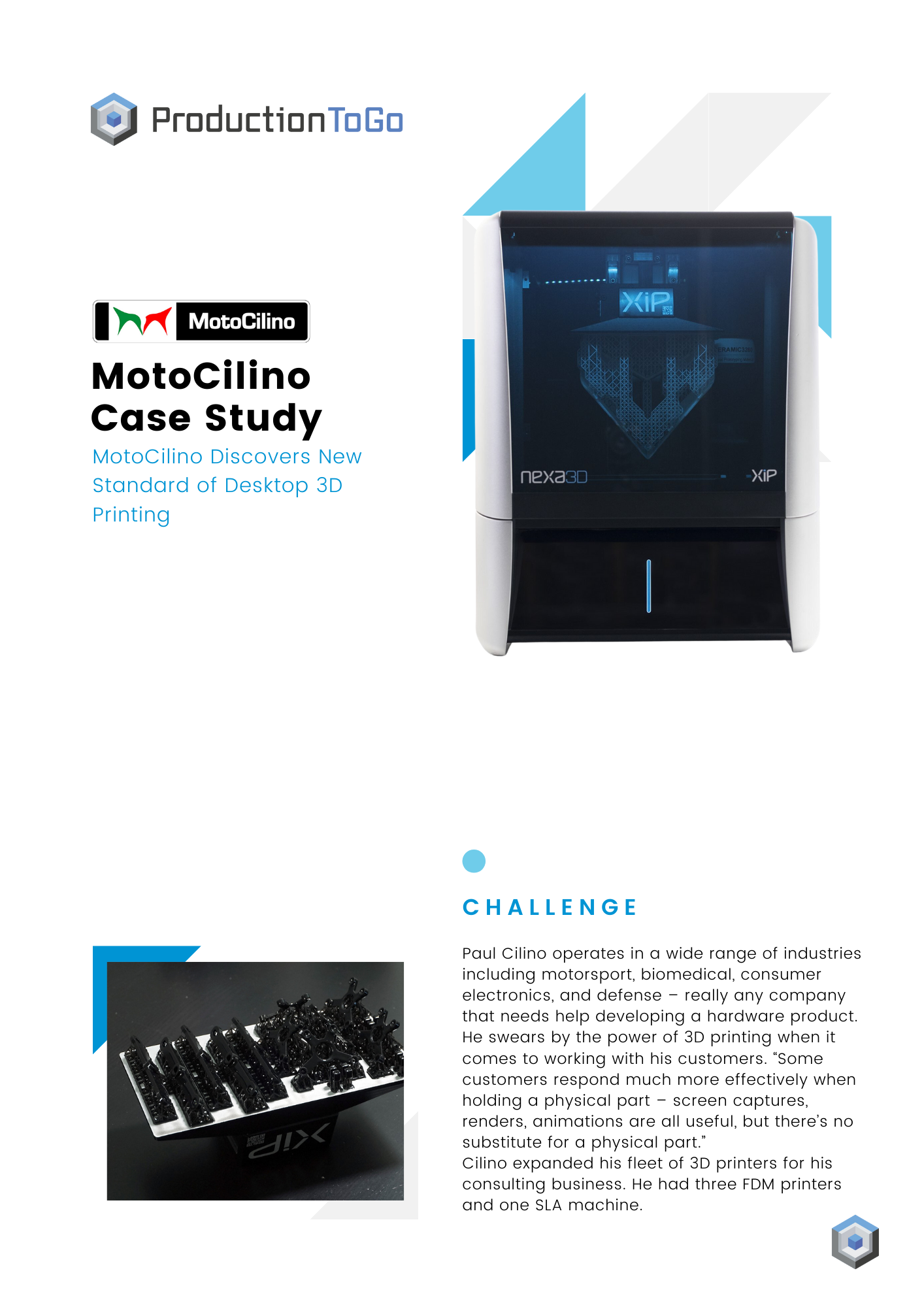

Paul Cilino operates in a wide range of industries including motorsport, biomedical, consumer electronics, and defense – really any company that needs help developing a hardware product. He swears by the power of 3D printing when it comes to working with his customers. “Some customers respond much more effectively when holding a physical part – screen captures, renders, animations are all useful, but there’s no substitute for a physical part.” Cilino expanded his fleet of 3D printers for his consulting business. He had three FDM printers and one SLA machine.

Fill up the form below and we will send you the data sheet by e-mail.

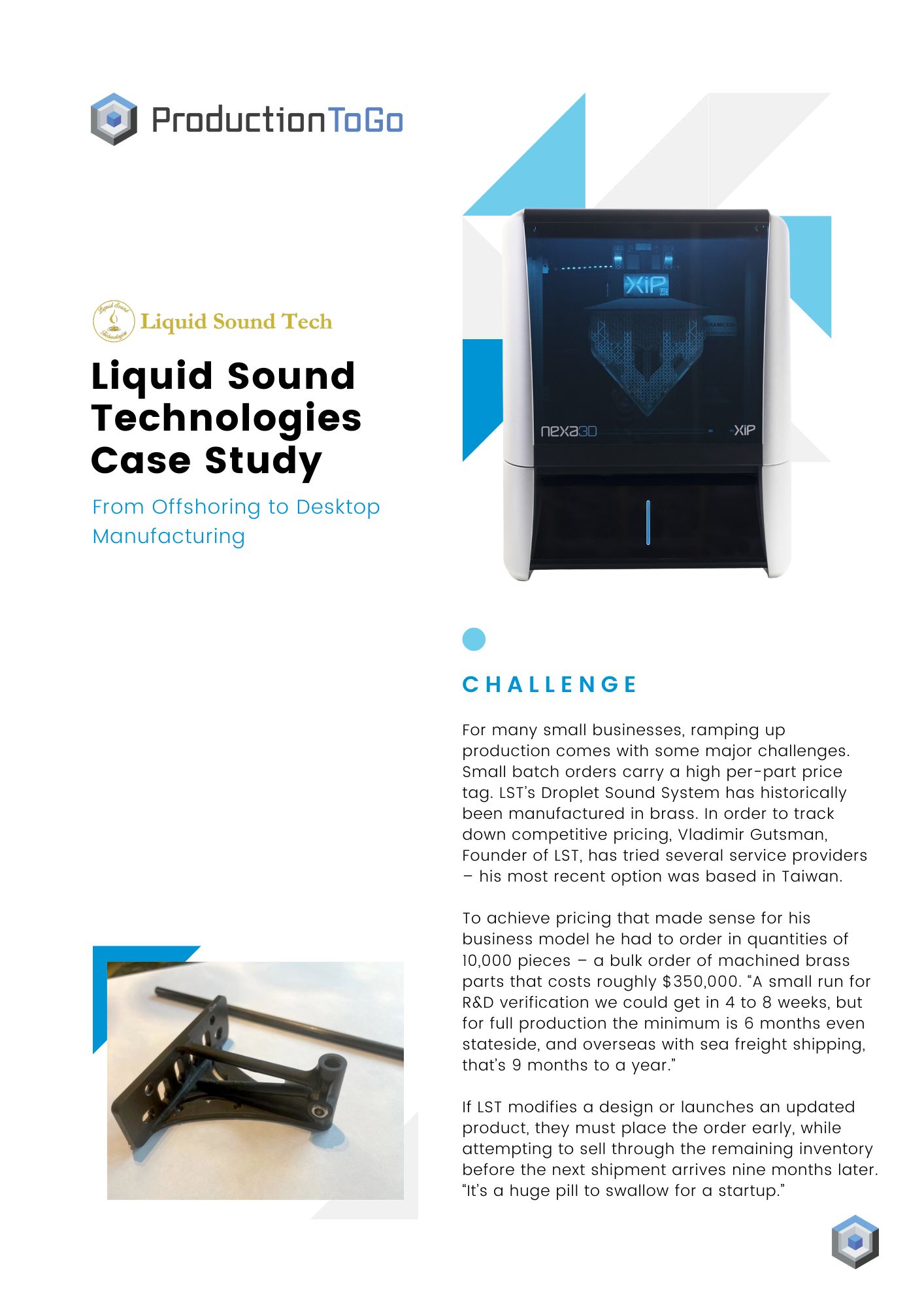

For many small businesses, ramping up production comes with some major challenges. Small batch orders carry a high per-part price tag. LST’s Droplet Sound System has historically been manufactured in brass. In order to track down competitive pricing, Vladimir Gutsman, Founder of LST, has tried several service providers – his most recent option was based in Taiwan. To achieve pricing that made sense for his business model he had to order in quantities of 10,000 pieces – a bulk order of machined brass parts that costs roughly $350,000. “A small run for R&D verification we could get in 4 to 8 weeks, but for full production the minimum is 6 months even stateside, and overseas with sea freight shipping, that’s 9 months to a year.” If LST modifies a design or launches an updated product, they must place the order early, while attempting to sell through the remaining inventory before the next shipment arrives nine months later. “It’s a huge pill to swallow for a startup.”

Fill up the form below and we will send you the data sheet by e-mail.

Leveraging this rich heritage, Innotech Marine was created to focus specifically on advanced IoT solutions for the sport fishing industry. The key challenge was to develop durable, professional-grade enclosures for prototype electronics without the time and financial investment traditionally required for tooling and production. It became clear that overmolding would be the ideal solution to ensure maximum protection for these components to avoid exposure to corrosive saltwater. Overmolding required careful consideration of materials, especially given the harsh marine environment in which these products would operate.

Fill up the form below and we will send you the data sheet by e-mail.

|

|

Photos from the event |

|

|

|

|

|

|

|

|

On-demand Webinar |

|

|

On-demand webinar |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy