3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

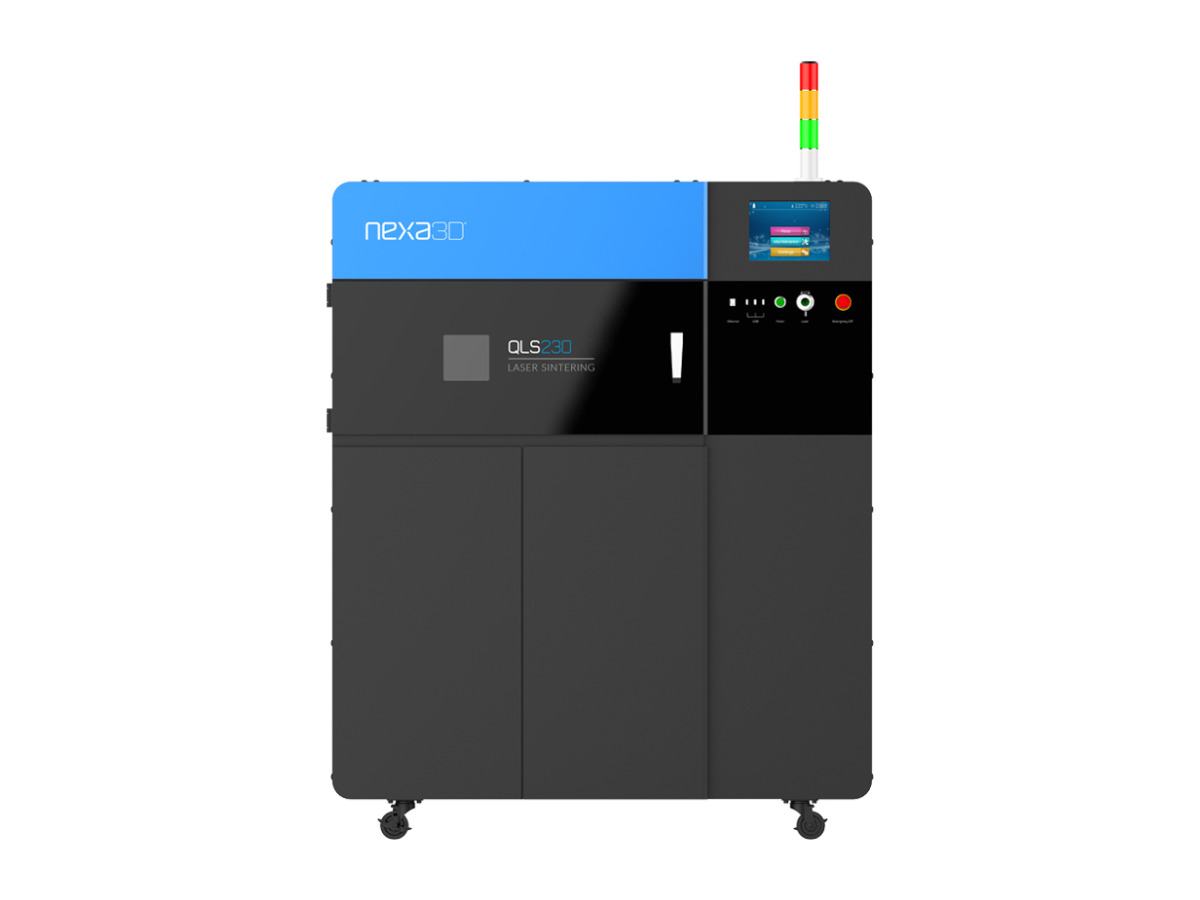

The Nexa3D® QLS 230 uses selective laser sintering (SLS) technology. Various plastic materials can be processed by users to produce intricate shapes and working prototypes.

Selective laser sintering (SLS) technology has long been the preferred platform for producing 3D-printed parts with robust, durable mechanical properties. Until now, most users have outsourced these parts due to the high cost of machine acquisition. The Nexa3D® QLS 230 makes this available to any prototyping user at an unprecedented price. With the Nexa3D® QLS 230, you can produce functional prototypes and small batches of high-quality plastics in the shortest possible time without support materials.

Key points:

Technology: SLS (selective laser sintering).

Build volume: 230 x 230 x 230mm

Laser power: 30W CO2

Max. Build speed: up to 20mm/hour (depending on geometry).

With the Nexa3D® QLS 230, a printing speed of up to 20 mm per hour is possible. The printer is therefore perfectly suited for production in small and medium-sized companies. During the D&D (Design & Development) phase, the design review and prototyping processes are accelerated, allowing users to quickly implement their product concepts. Costs are reduced and the entire process is accelerated by shortening the workflows.

The Nexa3D® QLS 230 is equipped with a 30 W CO2 laser and has a build volume of 230 x 230 x 230 mm.

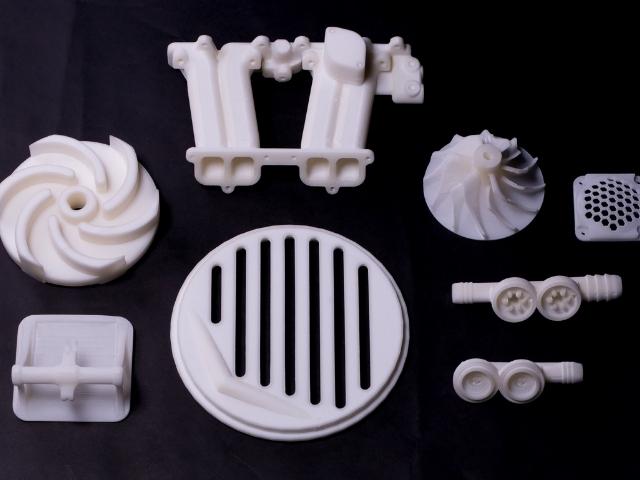

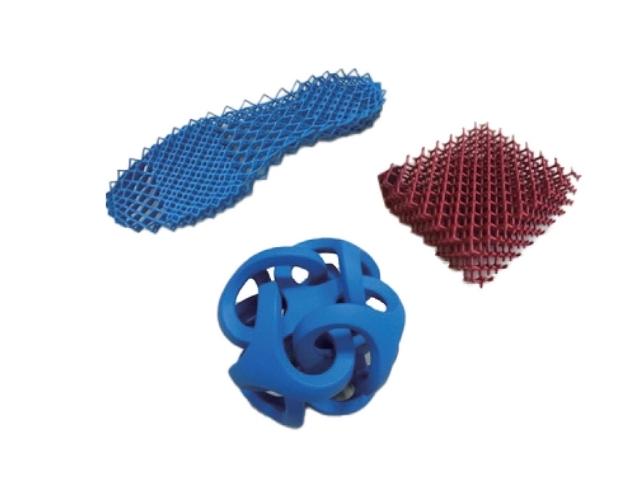

When using SLS technology, it is not necessary to print additional support materials, as the thermoplastic itself serves as the support material. As a result, the printing process conserves resources and the print result is not damaged. In addition, many models can be layered and printed in any direction. This increases productivity and reduces parts costs.

The Nexa3D® QLS 230 has 2 thermal field controls and its chamber can reach temperatures of up to 180 degrees Celsius.

The modular print chamber module of the Nexa3D® QLS 230 enables effective use of the robust system. With the help of the print removal tray, you can remove the finished prints from the printer and clean them afterward. This allows you to immediately start the next print without having to finish your parts beforehand. The removable print tray allows for cleaner and more effective removal of powder.

Cold Metal Fusion from Headmade Materials® is a patented process that combines the advantages of rapid sintering with established powder metallurgy processes for the production of titanium and steel parts. Using a polymer-coated metal powder, the QLS 230 produces "green" parts in a low-temperature processing environment. The parts then go through a secondary debinding and sintering process that burns out any residual polymer and sinters the metal particles together to form the final metal components.

Buildware and Nexa3Dprint® (XYZprint) AM SLS are two software programs used by Nexa3D® QLS 230. Buildware gives the user the ability to start printing directly at the printer. Project and print schedules, as well as monitoring of ongoing print jobs, is made possible by Nexa3Dprint® (XYZprint) AM SLS.

To always find the ideal material for external components and model elements, the Nexa3D® QLS 230 can use a wide range of materials.

End-use printing can even replace injection molded parts, metal replacement parts, components, automotive parts, and more.

Produce complex objects quickly and cost-effectively, in small runs or as individual pieces.

HP Multi Jet Fusion technology limits the recyclability of powder material. Once the limit is reached, the powder is end-of-life and can no longer be used. This means HP MJF customers must dispose of large quantities of powder. Now, this end-of-life powder can be recycled and printed on XYZprinting SLS printers. In addition, this powder can be easily mixed with as little as 5% fresh PA12 powder for brighter parts.

Review your design before you go into production. Test form, fit, and function with an accurate representation of the final product.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy