3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

The Nexa3D® QLS 820 is an industrial 3D printer for mass production with print speeds of up to 8,000 cm3/hr.

The Nexa3D® QLS 820 Sintered 3D Printer is a quad laser system that offers unmatched production capabilities and the highest part throughput in its class. It was designed with automation and scalability in mind. With up to four times the throughput of traditional laser sintering 3D printers and other polymer powder bed technologies, the Nexa3D® QLS 820 sets new standards for 3D printing.

Technical data:

Print volume: 49 liters

Build volume: 350 x 350 x 400 mm

Technology: Quad Laser Sintering

Pixel size: 50-200 µm

The Nexa3D® QLS 820 is the most powerful thermoplastic additive manufacturing solution on the market.

Thanks to its 100 W Quad CO2 lasers, this means up to 4 times the productivity increase over competing powder-based polymer 3D printing systems, with up to 8 liters of build volume per hour.

Numerous materials, including PA 12, PA 11, polypropylene, PBT, and aluminum , glass and fiber-filled polymers, can be converted thanks to a wide temperature range of up to 230 °C and an inert processing environment.

At launch, PA 12 is commercially available; PA 11, filled PA 12 and PBT will follow in the fourth quarter of 2022.

The system has a build volume of 350 x 350 x 400 mm with a variable Z-resolution of 50 to 200 micrometers.

The system offers a technology-neutral, open and automation-ready platform that integrates with everything from MES and ES systems to modular post-processing solutions.

The Nexa3D® QLS 820 is designed for optimal uptime thanks to its removable assembly. The user can start the breakout process with a simple switch, and a new assembly can be docked to the printer to start printing.

Increase ease of use and flexibility. Your adaptable printer fleet is designed to meet your growing manufacturing needs thanks to interchangeable units and modular material processing.

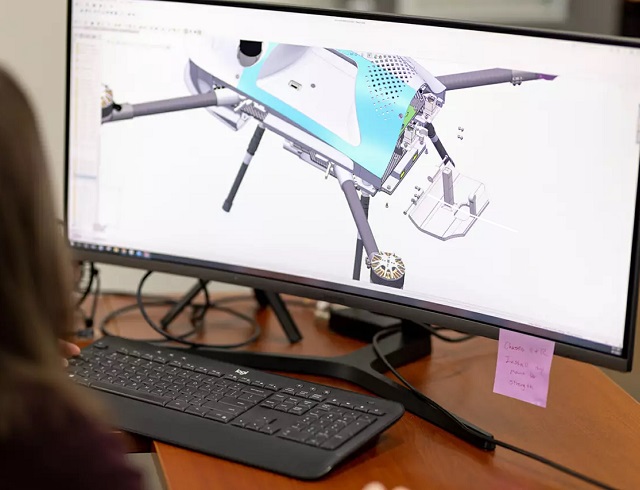

Using NexaX software, the Nexa3D QLS Command Center is a large touchscreen control station that provides real-time fleet management, print preparation, and printer status and performance from a single central location. In addition, NexaX for QLS provides remote access to QLS systems, increasing flexibility and ease of use. A fleet of printers can be accessed via the Command Center, a computer or a mobile device.

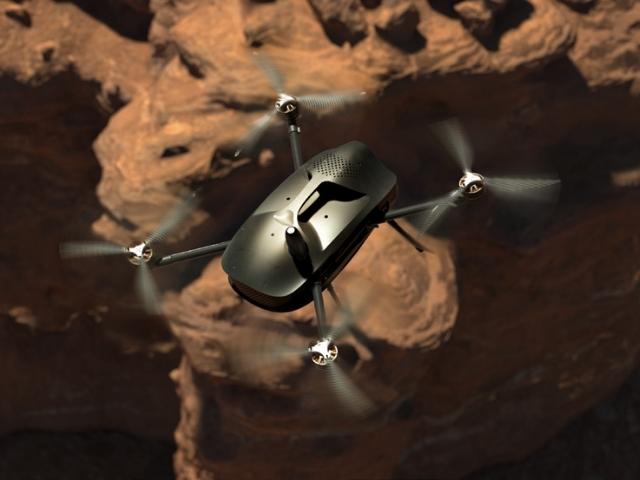

The Nexa3D® QLS 820 3D printer is best suited for professional use in a variety of industries, including automotive, aerospace and military, industrial manufacturing, medical, consumer products, and more. It is an excellent replacement for injection molding and is ideal for manufacturing durable end-use parts as well as high-temperature components.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy