3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

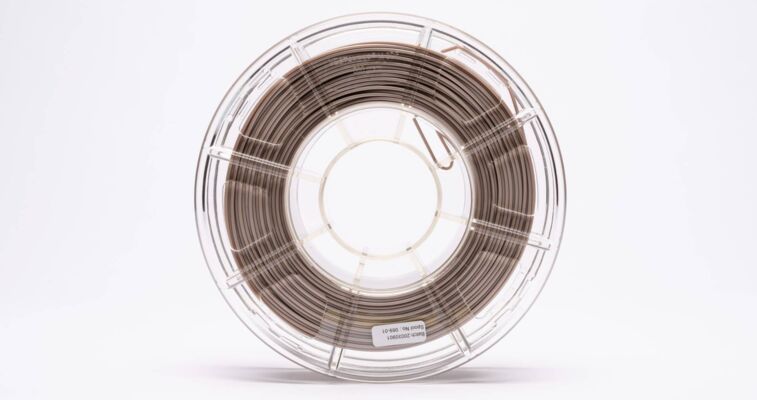

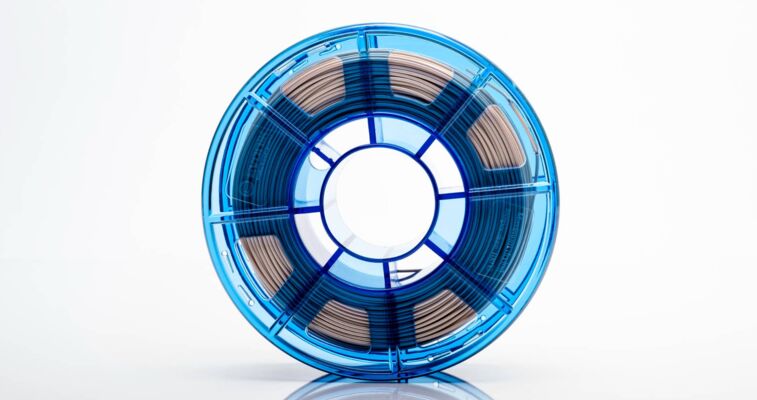

Evonik offers the industry’s most extensive portfolio of biomaterials used in the 3D printing of medical device parts designed for temporary and permanent body contact. New industrial grade filaments complete our portfolio.

Fused Filament Fabrication (FFF) with high-temperature thermoplastics such as PEEK, which are also suitable for aerospace applications, for example, has made considerable progress in recent years and has become an established process for 3D printing complex parts. 3D-printed parts made of PEEK exhibit outstanding properties.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy