3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

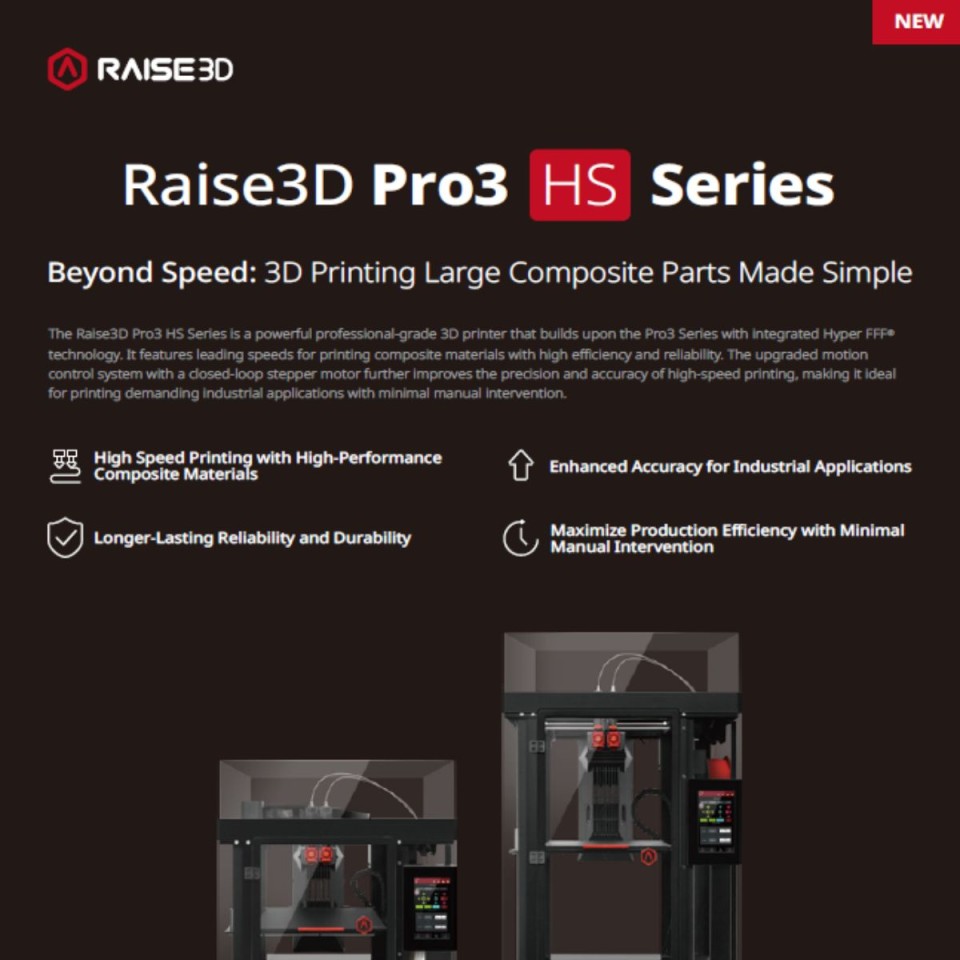

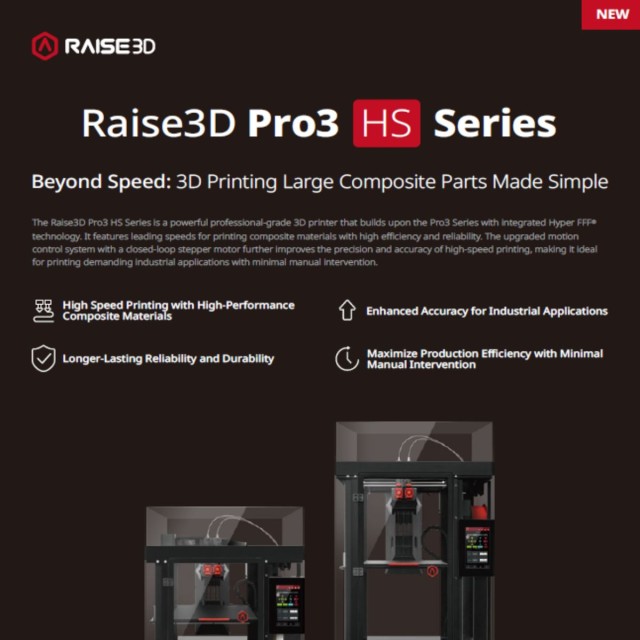

Expanding on the success of the Pro3 and now with integrated Hyper FFF® technology, the Raise3D Pro3 HS marks a major leap forward in professional-grade 3D printing technology. With its high-speed printing capabilities for composite materials that offer improved efficiency and dependability, this 3D printer is developed to fulfill the demands of industrial and professional applications alike.

The Pro3 HS offers high-speed printing capabilities for composite materials with improved efficiency and dependability, catering to the needs of industrial applications. In comparison to its predecessors, the Pro3 HS prints at a 30% to 70% faster rate thanks to its baseline speed of 300 mm/s and its ability to maintain average rates of 200–300 mm/s even when utilizing high-performance materials.

Some of the main enhancements are an auto filament switching function that enables continuous production with up to 5 kg of material, a redesigned build plate for consistent magnetic adhesion and faster heating, and a closed-loop stepper motor for accurate motion control that reduces noise by over 27%.

Technical data:

Build Volume: 300 x 300 x 300 mm (single extrusion) / 255 x 300 x 300 mm (dual extrusion)

Maximum Nozzle Temperature: 320°C

Maximum Build Plate Temperature: 120°C

XYZ Step Size: 0.78125, 0.78125, 0.078125 μ

Hyper FFF® technology, which allows for accurate and dependable high-speed printing, is incorporated into the Pro3 HS. By utilizing an active vibration reduction algorithm and a high-flow rate hot end, this technology enables the printer to print at standard speeds of 300 mm/s. The printer can sustain typical rates of 200-300 mm/s even while using Hyper Core high-performance materials, which results in a 30% to 70% reduction in printing time when compared to the current Raise3D Pro3 Series.

The Pro3 HS has a closed-loop stepper motor in the transmission system to guarantee accuracy at high speeds. With the help of this improvement, double-diaphragm couplings, and an optimized shaft structure, precise high-speed printing without step loss is possible. Additionally, the upgraded motion control system lowers noise by more than 27%, improving the user experience overall.

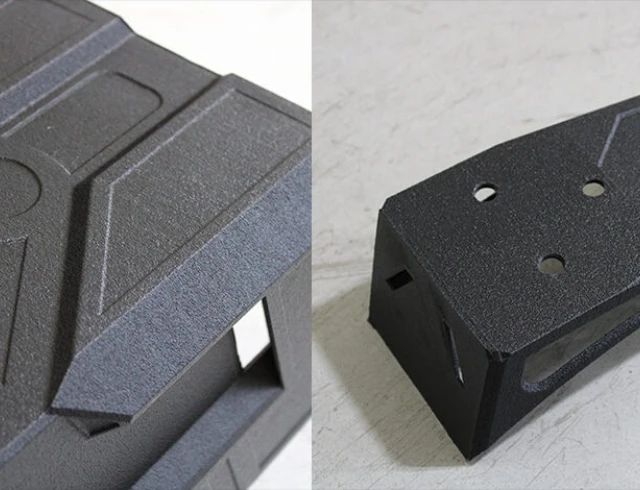

Hyper Core and Industrial high-performance materials, as well as other composite materials, can be printed at fast speeds with the Raise3D Pro3 HS. Because of these capabilities, it's perfect for creating end-use parts that match the rigorous standards and requirements of industrial users while operating successfully in demanding situations.

The auto filament switching capability of the Pro3 HS is one of its best features. Continuous production is made possible by the second extruder's ability to print from a different spool of filament when the first one runs out. Up to 5 kilograms of material can be printed continuously with the printer thanks to its capacity for two larger 2.5 kg filament spools. This function lowers the requirement for manual intervention while greatly increasing manufacturing efficiency.

Long-term dependability is a key component of the Pro3 HS design for high-volume industrial printing applications. It has an all-metal nozzle, a tested all-metal frame, and a reinforced hot end. Further enhancing its capacity for longer production runs is the dual-gear extruder.

Model warping is lessened with the redesigned build plate, which provides consistent magnetic adhesion. Additionally, it is 1 mm smaller than earlier models, which enables it to heat up to 100°C two minutes faster and increase print efficiency overall.

In order to ensure successful prints and avoid the use of the wrong materials, a newly-added RFID filament sensor will detect the type of filament and confirm the required settings. This sensor will be available soon.

The printer has cloud control capabilities and several connectivity options, including Ethernet, Wi-Fi, and USB.The software ecosystem of Raise3D is easily integrated with the Pro3 HS Series and consists of the following:

ideaMaker: A program for 3D slicing that creates models ready for printing

ideaMaker Collection: A blueprint for open-source software

RaiseCloud: Software for remote management of 3D printing in the cloud

Produce functional prototypes for testing and validation, create multiple design iterations in a shorter timeframe and fabricate complex geometries that might be difficult to achieve with traditional manufacturing methods.

Produce full-scale prototypes for ergonomic testing. Print full-scale parts to verify assembly processes before final production. Experiment with different materials to find the best fit for specific product requirements and utilize the printer's capability to work with composite materials for advanced industrial and prototyping needs.

Produce custom interior components or specialized parts for limited edition vehicles. Manufacture complex, lightweight structures for small satellite components or drone parts.Create customized medical devices or prosthetics in small quantities. Produce limited edition or personalized product runs and manufacture specialized tools, jigs, and fixtures for specific production processes.

Create specialized holders or guides to improve assembly efficiency and accuracy. Design and print tools that reduce operator fatigue during repetitive tasks. Produce custom measurement tools for specific parts or products and design and print fixtures to hold parts in precise positions during welding operations.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy