3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

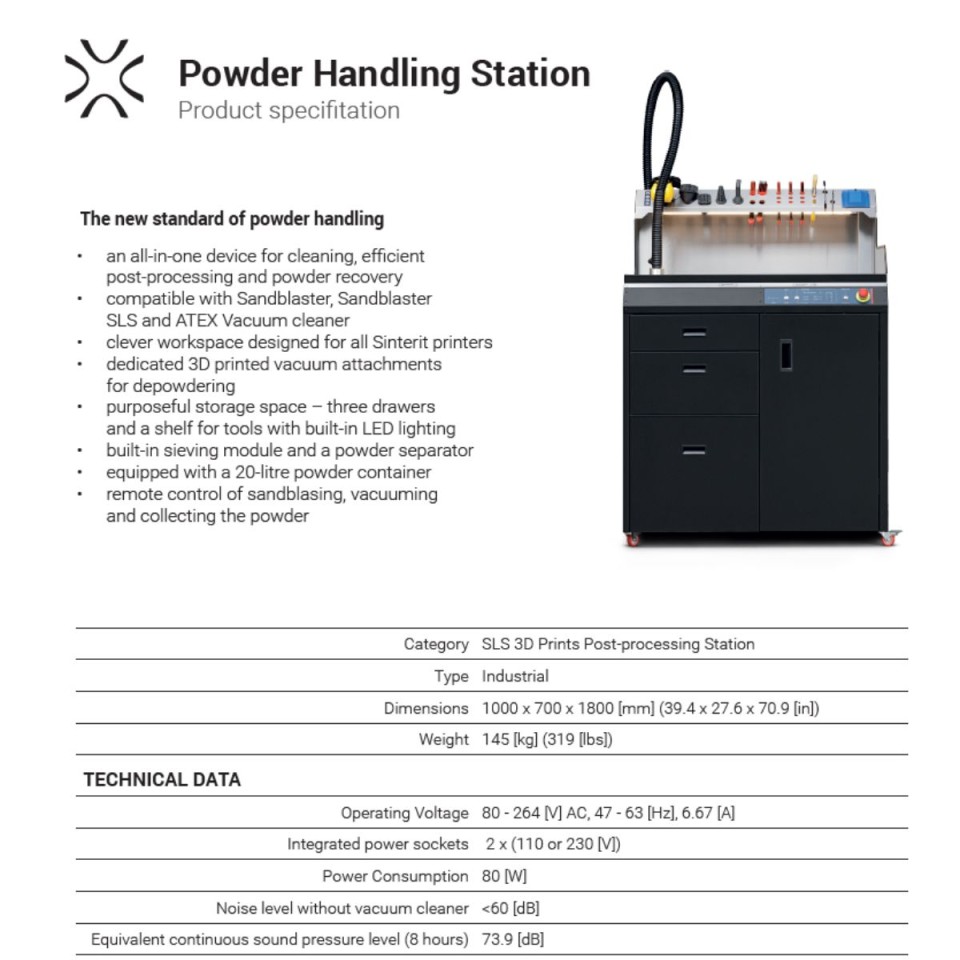

The Sinterit PHS is an efficient post-processing station of 3D printed parts and quickly recovers up to 95% of the unsintered powder during selective laser sintering.

The Sinterit Powder Handling Station provides users of the Sinterit Lisa, Lisa PRO, Lisa X, and NILS480 systems with an ergonomic work area that allows easy and clean post-processing and powder recovery.

It can be used with other SLS 3D printing systems and is compatible with Sinterit's ATEX industrial vacuums. The system features a special 3D-printed vacuum inlet for depowering, storage space for various tools, a built-in sieve module and is compatible with Sinterit's standard powder containers.

Technical data:

Suction opening: 40 mm

Powder capacity: 20 liters

Filter type: HEPA

The cleaning hose, powder chamber, powder separator, powder sieve module, and hopper of the collection system provide maximum powder recovery, allowing you to reuse powder and reduce costs. The Sinterit PHS set also includes two powder chamber grids, two containers, a powder scraper, a tube brush, and nozzles for precise suction and depowering.

The Sinterit ATEX vacuum and sandblasting solutions can be easily connected to the PHS.

The Sinterit PHS has a capacity of 20 l and is compatible with all Sinterit powders. It can be used by both small and large industrial machines.

To ensure that operating costs remain low and no components wear out during use, the Sinterit PHS contains virtually no plastic components.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy