3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

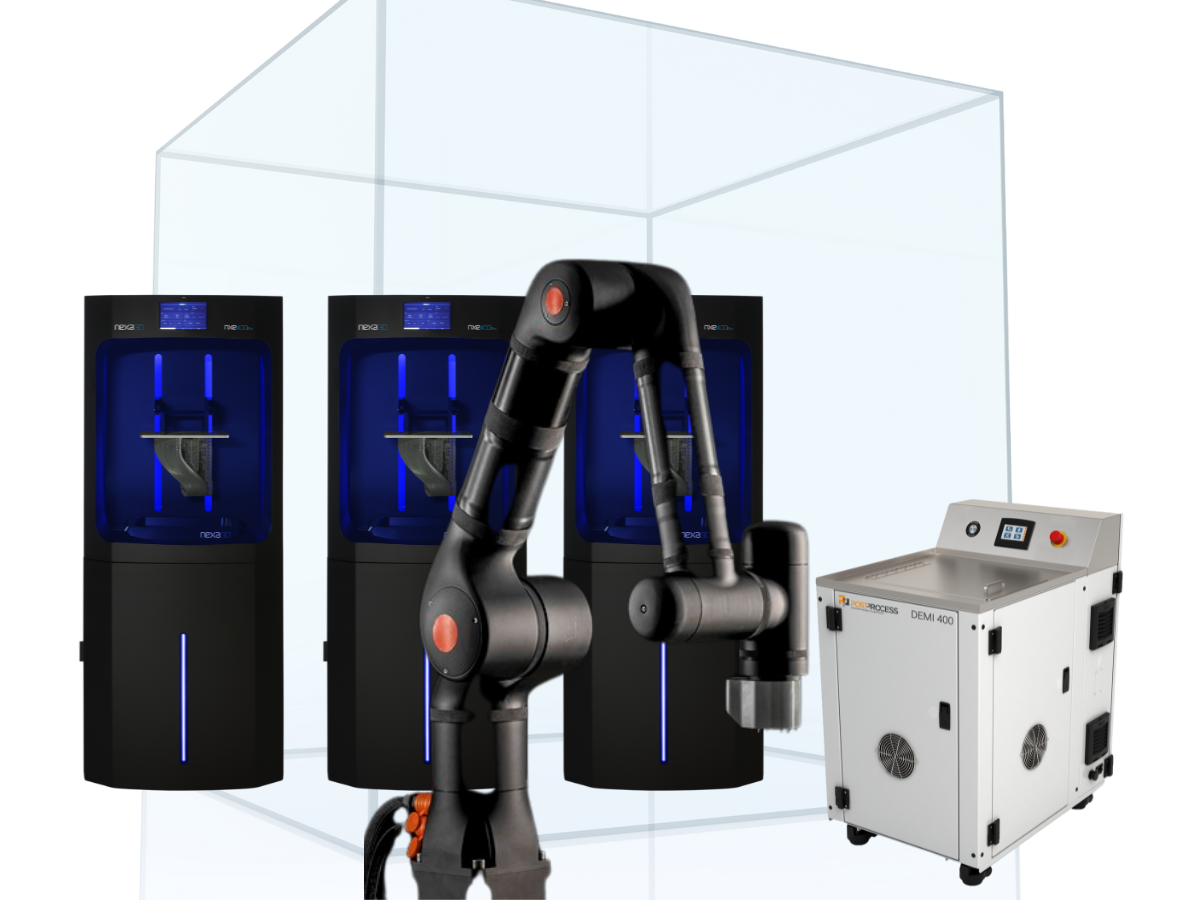

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send EmailIn the context of 3D printing manufacturing, automation means the use of equipment to automate 3D systems or processes. The systems include various technologies and can be easily distinguished by material groups (metal, resin, polymer powder and filament). The processes, in turn, are differentiated according to a number of stages, but mainly include 3 main stages. The pre-printing stage (e.g. loading the material, cleaning, preparing, etc.), the printing stage (e.g. uploading files, connecting to the USB port, setting parameters, starting the print, etc.) and the post-printing stage (e.g. surface treatment, washing, curing, depowdering, blasting), all of which vary according to machine type and technology.

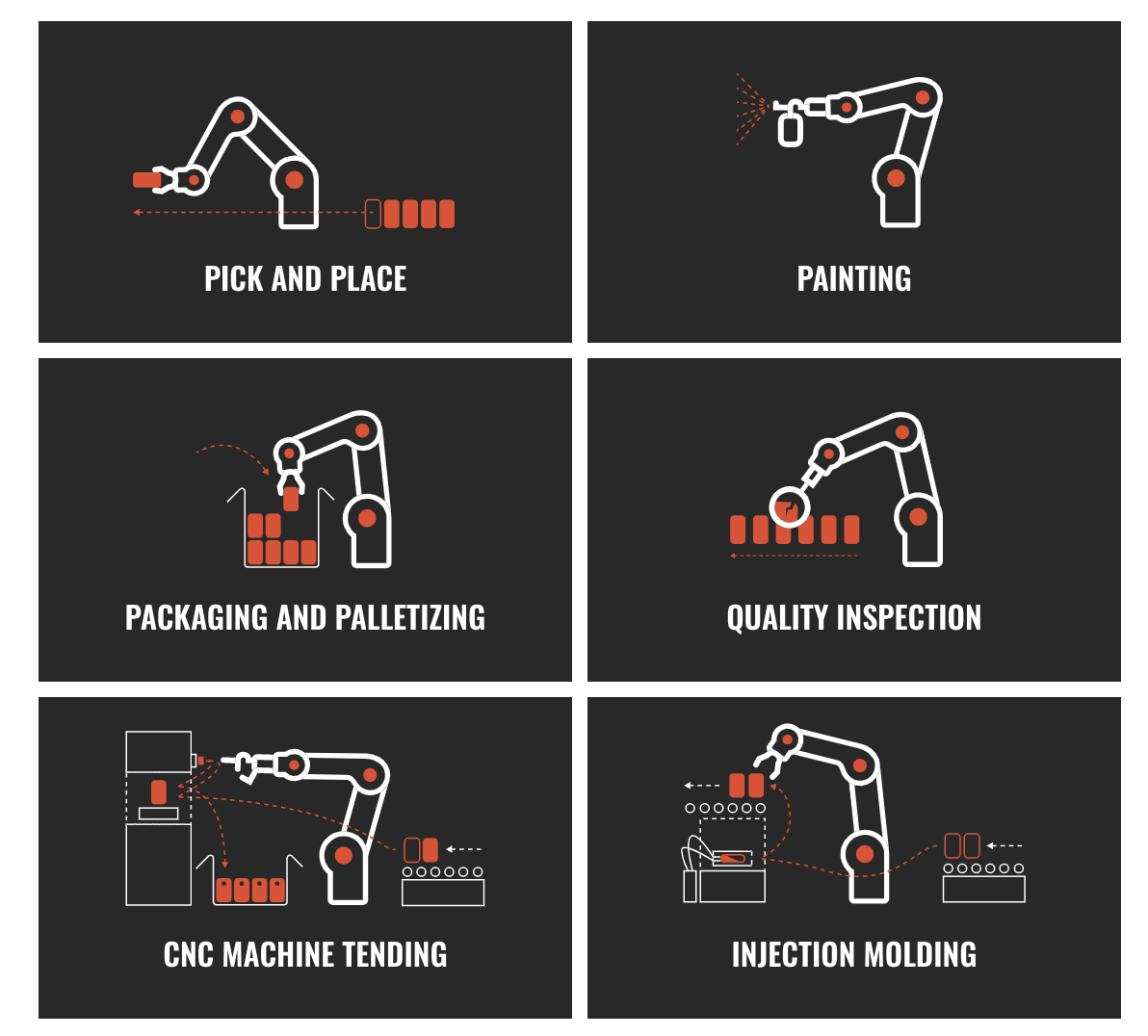

The goal of 3D printing automation for manufacturing is to increase production capacity while reducing costs. Electromechanical systems can be programmed to perform a variety of tasks, and automation is especially helpful for repetitive tasks or tasks that require extreme precision.

With Kassow Robots we offer a wide range of industrial collaborative robots for industrial applications and human collaboration. All Kassow robots have 7 axes, resulting in greater maneuverability and less space requirements.

Even for complex specialized tasks, there are hardly any limits. For example, in adhesive applications, the robot follows an exact path and maintains the specified speed, regardless of the type of movement. As a result, the robot completes the task smoothly and repeatably.

Together we automate your production, reduce costs and increase your production output. Ideal for applications with short cycle times like CNC machines and 3D printer farms.

If you have a specific project, please contact us!

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy