3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

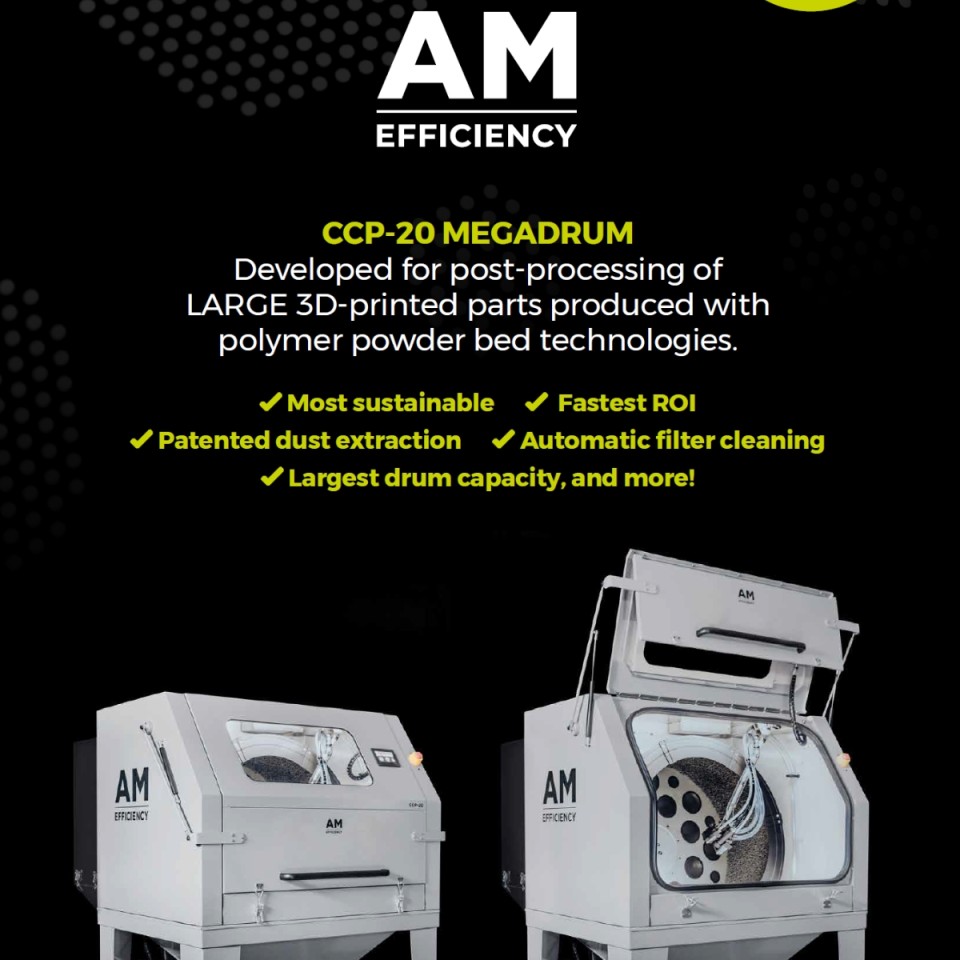

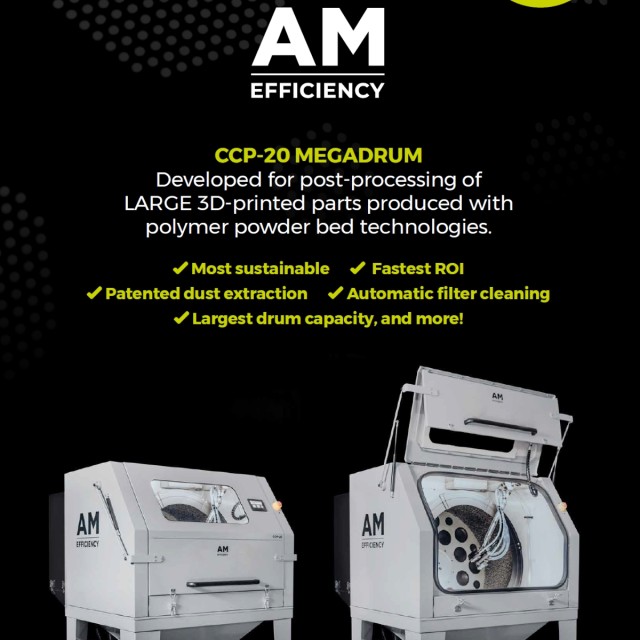

The CCP-20 Megadrum is a cutting-edge automated machine designed for cleaning and post-processing of very large 3D printed parts or managing large scale batches. By simply changing the media and process program, it can perform three essential processes: Cleaning, Cleaning and Coloring, or Polishing.

Built from the success of the CCP-2, the CCP-20 offers a “Megadrum”; a larger drum where parts produced with polymer powder bed technologies can be post-processed. Whether you’re working with SLS, MJF, SAF, or HSS AM technologies from HP, Eos, Stratasys, 3D Systems, Farsoon, Voxeljet and more, the CCP-20 Megadrum is your ultimate solution!

This innovative solution features ideal post-processing for 3D-printed components, local manufacturing, and low energy consumption, making it an exceptionally sustainable choice for your production needs.

Key features:

- 3-in-1 post-processing

- Small footprint

- Largest CCP drum size

- Fast and versatile

There is no need to waste space and money on many devices that serve effectively the same purpose. De-powder the components using the “Cleaning” material and the pre-programmed cleaning routine. Use the "Cleaning and Coloring" blast media to produce a consistent, stunning dark gray color on your parts and switch to the “Polishing” material and begin the program to polish the pieces until they have an impeccable and shiny finish.

The CCP-20 Megadrum offers a significantly larger drum volume of 227 liters compared to the CCP-2's 65 liters, allowing for processing of much larger 3D printed parts. While both machines have the same cabinet volume of 990 liters, the CCP-20 Megadrum has a more compact overall footprint (1250 x 1250 x 1675 mm) than the CCP-2 (1350 x 1100 x 1760 mm), making it more space-efficient despite its larger drum capacity.

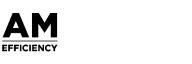

The AM Efficiency CCP-20 Megadrum finishing station includes a unique patented extraction and separation mechanism. This provides the system with significant advantages in various ways, as cleaning powder bed 3D printed components necessitates the removal of enormous amounts of loose powder. Conventional blasting methods are not intended for this purpose. The AM Efficiency CCP-20 Megadrum separates the powder straight from the abrasive. This enables the system to ensure greater reliability and reproducibility in manufacturing. Separated powder leftovers can be recycled more effectively.

To enable an efficient workflow, the AM Efficiency CCP-20 Megadrum similar to the CCP-2 is equipped with a removable drum that can be easily transported to the next step of post-processing after the operation.

Completely automated cleaning, dyeing, and polishing programs. Each software is designed to provide the most efficient workflow. Each program consists of a sequence of blasting, ionization, and extraction processes that ensure the printed parts are free of static electricity and dust.

The “Cleaning” specialized bead blast post-processing powder is meticulously crafted for cleaning 3D printed parts. Compromising primarily of glass beads in carefully balanced sizes, this media ensures optimal cleaning performance while facilitating efficient recycling in the CCP systems.

The “Cleaning and Coloring” powder designed for dual dry post-processing functions - cleaning and coloring - is tailored for gray or dark colored 3D printed parts. The media consists primarily of finely balanced particles infused with dark pigment, ensuring superior cleaning performance while imparting a rich, darker tone to the parts.

The “Polishing” powder which is ideal for applications following the cleaning stage features a specially balanced blend of polymer powder or beads meticulously crafted to deliver a transformative process where surface imperfections are smoothed out, peaks are removed through peel shot technique and surface porosities are sealed resulting in a glossy, durable and scratch-resistant finish.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy