3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

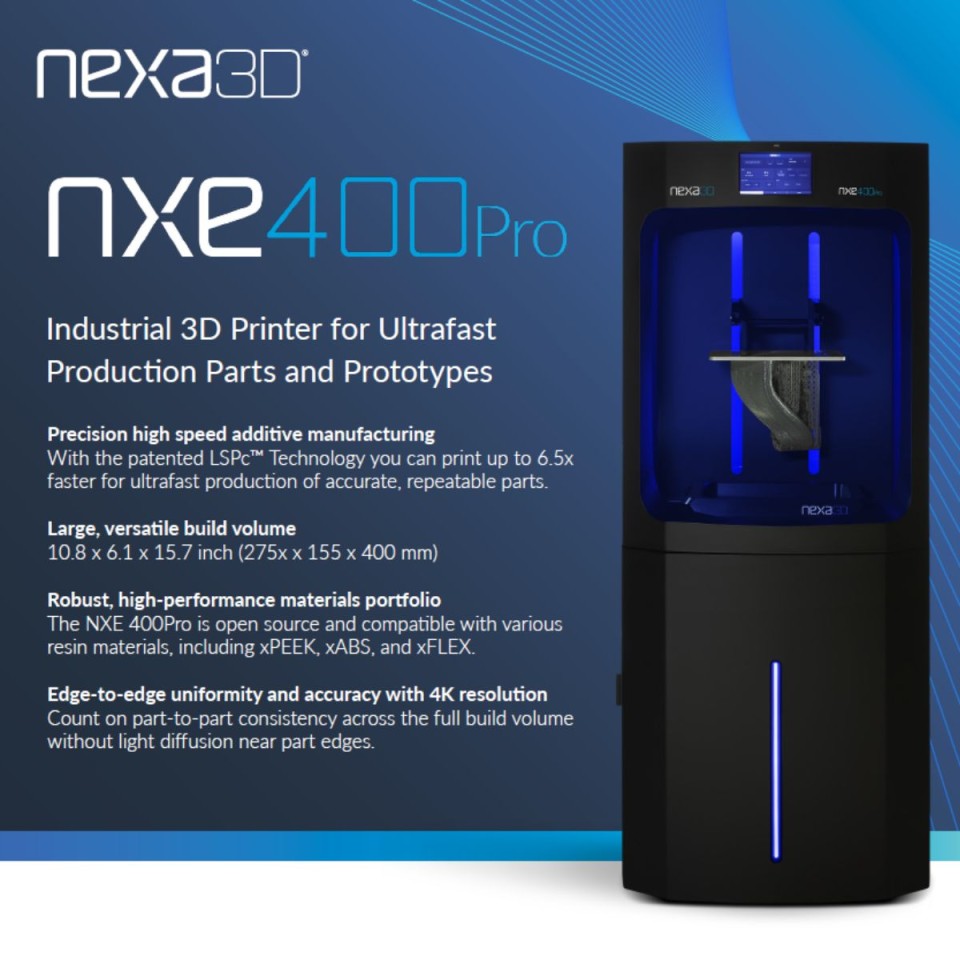

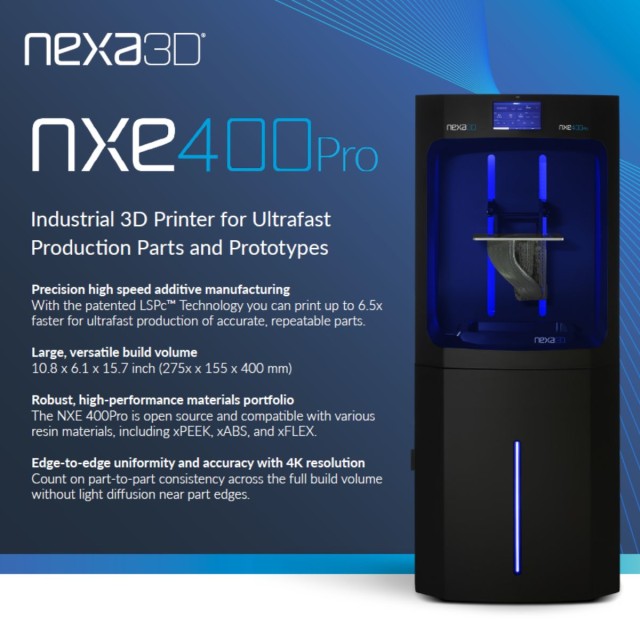

LSPc® technology (Lubrincant Sublayer Photo-curing) enables the rapid production of series parts and functional prototypes. The printer can achieve dimensional accuracy within a tolerance of 76.5 µm in XY on the entire build plate.

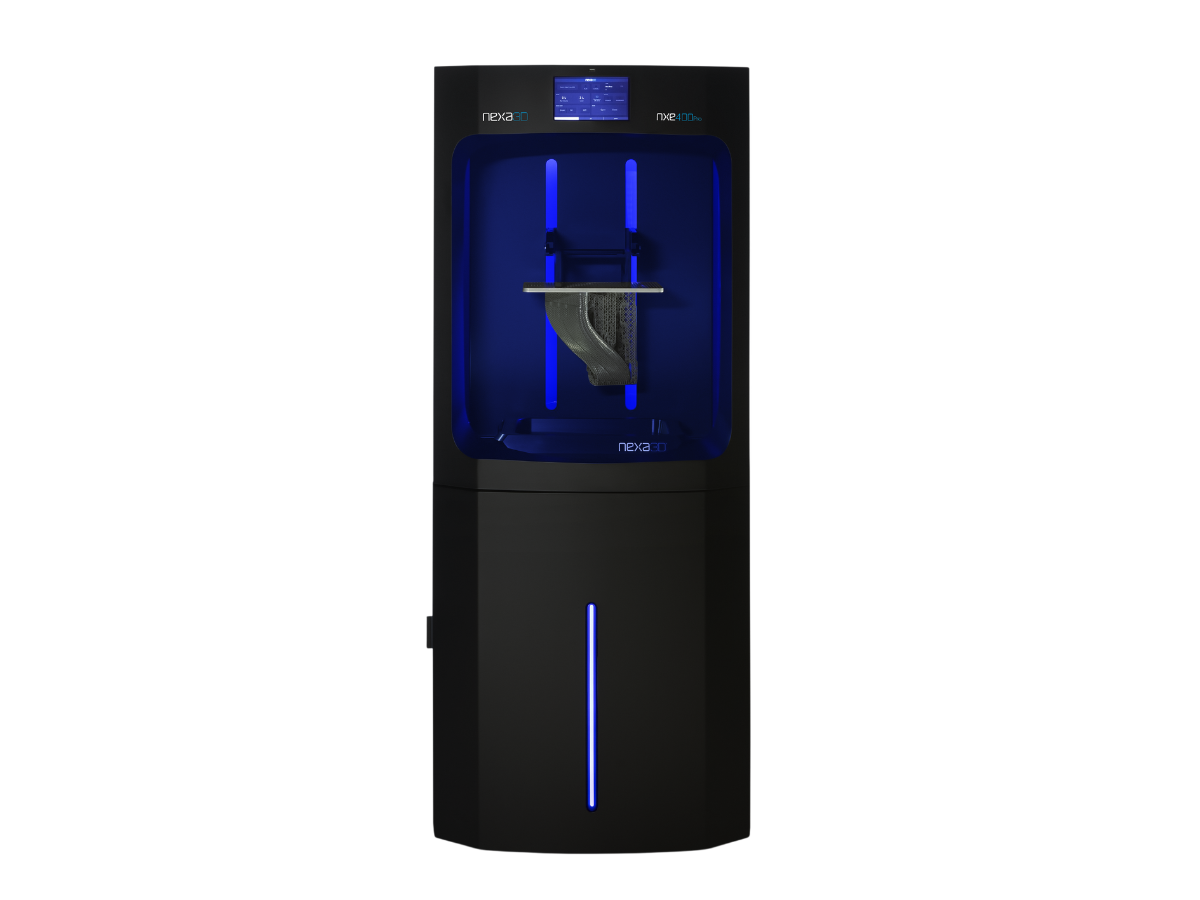

With an exceptional build capacity of 17 liters, the Nexa3D® NXE 400Pro photopolymer 3D printer delivers unmatched throughput at the highest build speed in its class, without sacrificing precision or process reliability. The Nexa3D® NXE 400Pro industrial 3D printer's proprietary LSPc® (Lubricant Sublayer Photo-curing) technology offers smoother surfaces, higher precision and smaller tolerances compared to SLA 3D printing.

Technical data:

Print volume: 17 liters

Build volume: 274 x 155 x 400 mm

Technology: 4K (3840 x 2160)

Pixel size: 76.5 µm

The Nexa3D® NXE400Pro features the following improvements over the Nexa3D NXE400:

1. Higher throughput - The Pro series uses the latest generation Nexa3D® light engine in combination with the patented Everlast membrane technology, the pull-off forces are minimized, thus a higher pull-off speed can be used.

2. Expanded resin portfolio

3. Improved process reliability - an improved auto-homing algorithm optimizes the adhesion of the first baselayer to the build platform

4. Two build plate designs (solid and slotted) - the solid build plate is designed to increase the effectiveness of post-processing and is compatible with low-viscosity resins. For higher viscosity resins, there is still an optimized version of the hardened slotted design.

5. New setting profile manager in NexaX software - users now have the ability to create open material profiles for their own or third-party resins.

6. Armored LCD Mask - resistant to wear and tear during the printing process.

[NOTE: All Nexa3D® NXE 400 printer owners, can purchase an upgrade kit to the Pro version].

Benefit from faster print times without compromising part quality or accuracy. The Nexa3D® NXE 400Pro's proprietary LSPc® technology is up to 6.5 times faster than traditional SLA and DLP 3D printing methods.

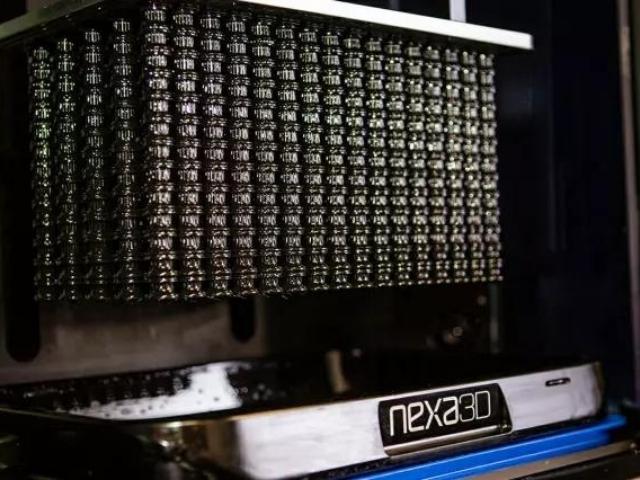

The Nexa3D® NXE 400Pro photopolymer 3D printer has a build volume 2.5x larger (17L) than other SLA and DLP-based technologies in its class. This allows it to print significantly larger parts, higher part throughput and ultimately lower part costs - all at higher resolution and detail (76.5 µm).

LSPc® ensures part-to-part accuracy and uniformity by projecting a consistent, powerful, distortion-free image across all areas of the build plate.

This completely eliminates the degradation known from conventional DLP systems in the peripheral areas.

For a faster workflow, the xWash and xCure post-processing systems complete the overall process.

You can rely on consistent part quality across the entire build volume.

High-quality modular units and components that can be easily replaced facilitate maintenance and ensure durable use of the device.

Strong alliances with leading material suppliers such as Henkel, BASF and Evonik extend Nexa3D®'s extensive material selection.

These photopolymers are developed specifically for the LSPc® process to ensure highly efficient build processes, robustness and accuracy.

Only a diverse selection of fully validated materials, allows to get the most out of the ultra-fast LSPc® technology and to support you in your application in the best possible way.

Analyze parts for the ideal printing process and use the material selector and automated support algorithm to achieve the best material properties and reduce costs.

With LSPc® technology (Lubricant Sublayer Photo-Curing), you can print your parts with lightning speed and process reliability with the Nexa3D® NXE 400Pro.

To wash off the excess resin, the printed parts are cleaned with either the Nexa3D® xWash or another wash station.

In order to achieve the specified material properties, the printed parts must be post-exposed using either the Nexa3D® xCure or another post-curing device.

Call or email us and we will be happy to help you.

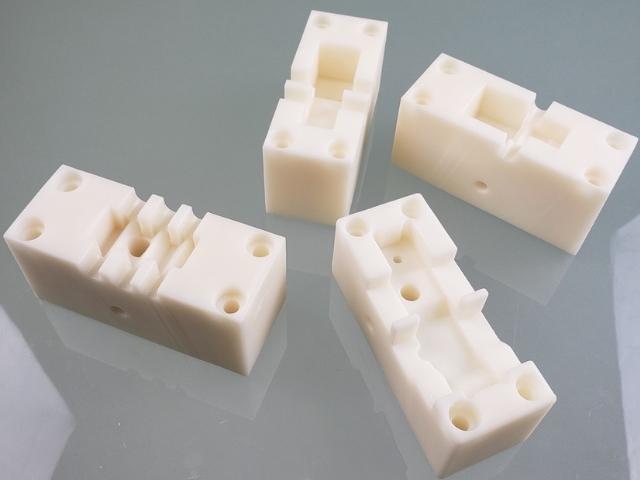

Verify your design before you go into production. Test form, fit and function with an accurate representation of the final product.

Produce complex objects quickly and cost-effectively, in small batches or as individual pieces.

With the Nexa3D® NXE 400Pro, manufacturing and assembly processes become easier and more reliable, cycle times are reduced, and worker safety is improved.

3D printed injection molds can accelerate product development and provide the ability to prototype from the original manufacturing process and material.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy