3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

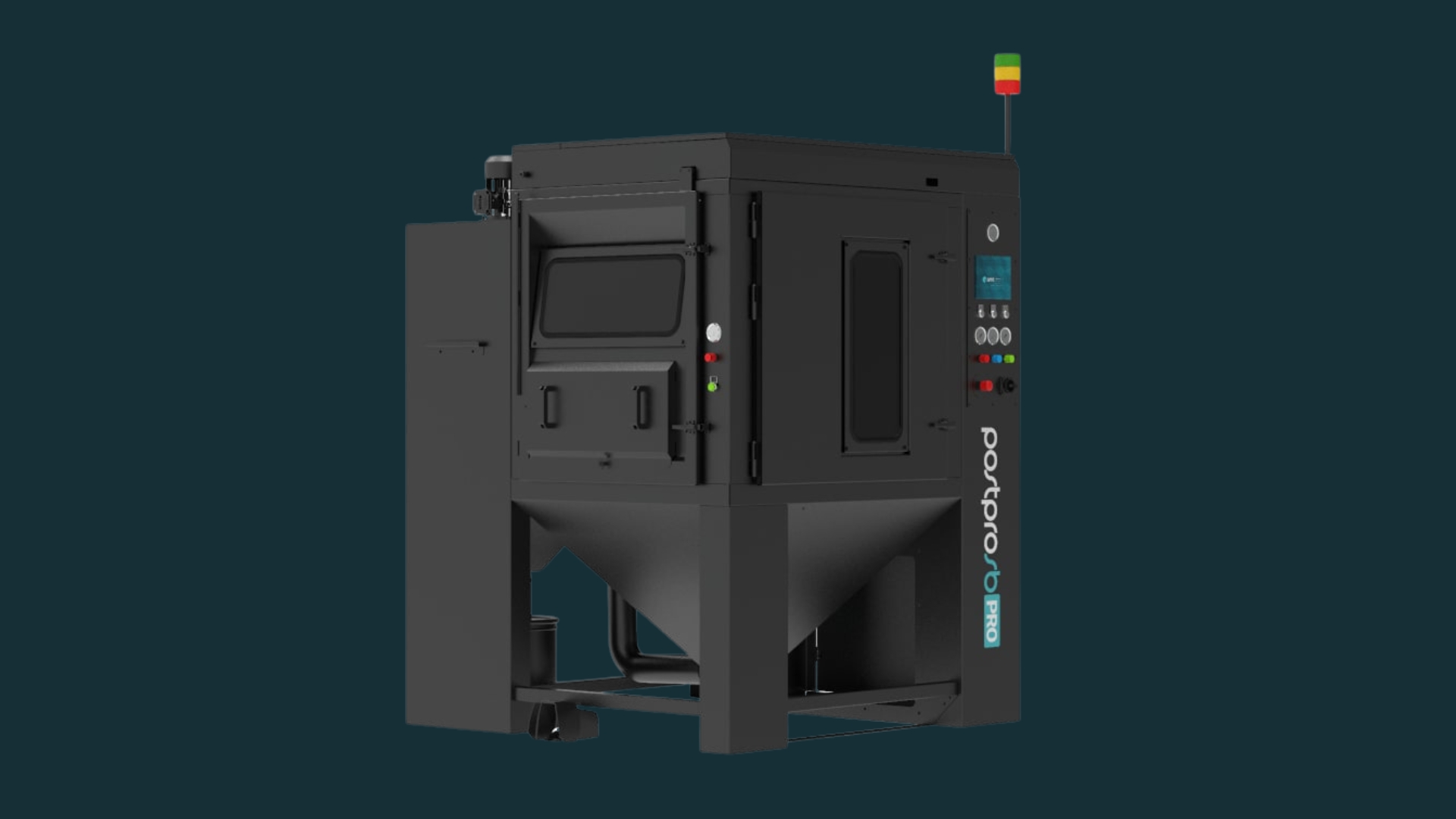

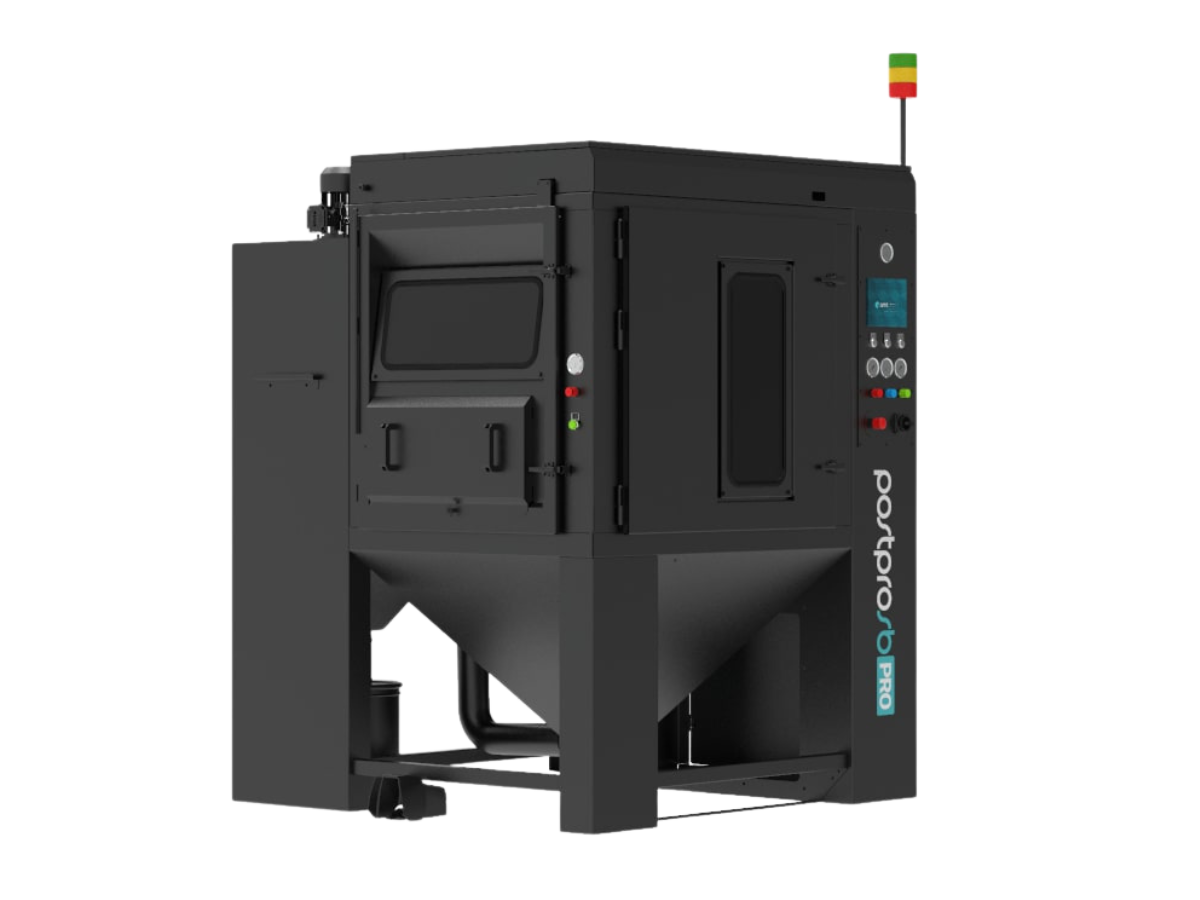

The PostPro SB PRO is an advanced automated surface blasting system designed to enhance the finishing quality of 3D printed parts by efficiently removing excess powder and improving surface smoothness.

The PostPro SB PRO is a cutting-edge automated surface blasting system specifically designed to enhance the finishing quality of 3D printed parts. This advanced machine utilizes mechanical methods, such as shot blasting, to efficiently remove excess powder and improve surface smoothness, ensuring that components meet the high aesthetic and functional standards required in industries like aerospace, automotive, and medical devices.

The PostPro SB PRO includes a dedicated manual blasting area, which greatly increases its versatility and efficiency in post-processing 3D printed products. This separate sector allows operators to quickly blast heavy components without changing the automated blasting area's settings or setups. This capability is especially useful for manufacturers who frequently work with variable part sizes, since it allows for quick transitions between different production runs while retaining peak performance.

The ability to manually blast parts guarantees that large or unusually shaped components can be processed efficiently, saving downtime and increasing total throughput in the manufacturing line. In addition to manual blasting capabilities, the PostPro SB PRO is ergonomically constructed, allowing operators to work comfortably and productively. The manual blasting area's vast size enables for easy access and manipulation of larger pieces, which are sometimes difficult to handle in standard systems. Operators may easily change the blasting angle and parameters, optimizing the cleaning process for each unique part geometry.

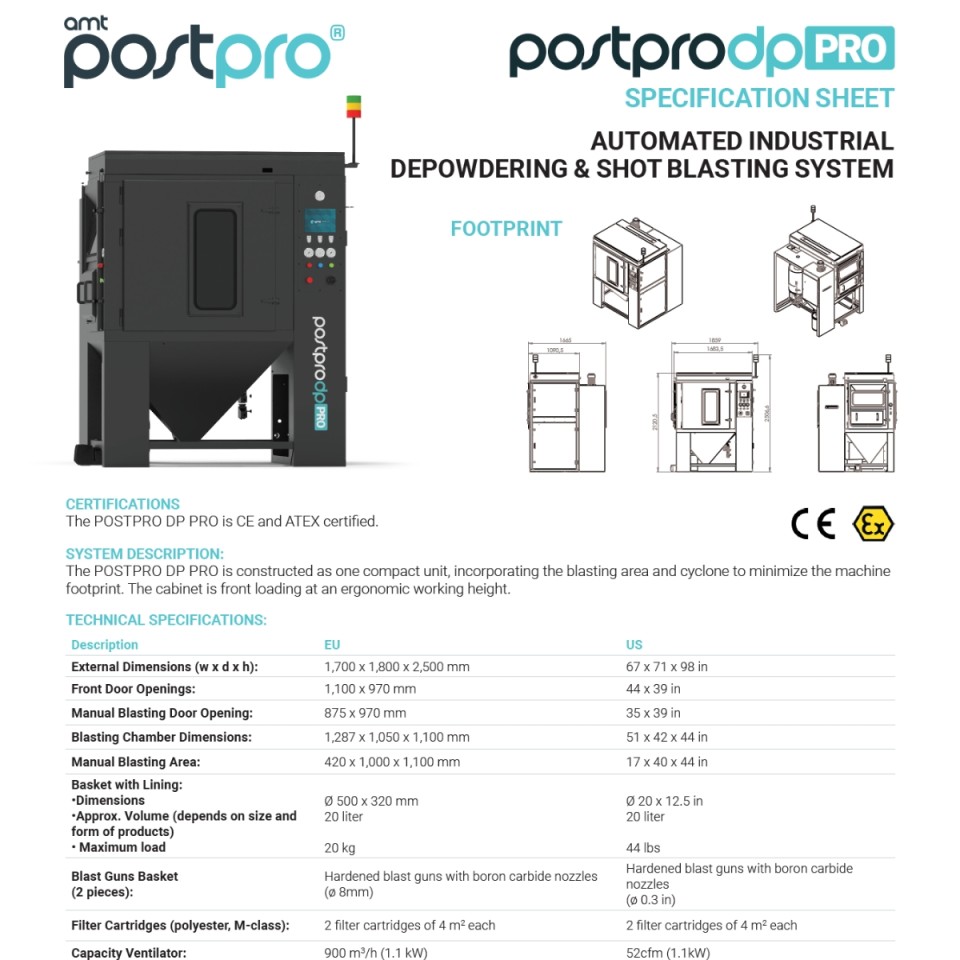

Technical specifications:

Blasting Chamber Dimensions: 1287 x 1050 x 1100 mm

Manual Blasting Area: 420 x 1000 x 1100 mm

Basket With Lining Dimensions: Ø500 x 320 mm

Basket Volume: 20 liters

Basket Loading Weight: 20 kg

Blast Gun (Basket): Double with Ø8 mm nozzle

Blast Gun (Manual): Single with Ø8 mm nozzle

The PostPro SB PRO uses automated surface blasting technology to effectively remove surplus powder from 3D printed components. This procedure uses compressed air and specialized blasting media to clean the parts thoroughly without causing damage. By automating this essential post-processing step, the system considerably minimizes the need for personal intervention, which can frequently create variability and inconsistency in the final findings. The flexibility to set particular recipes for different materials and geometries guarantees that manufacturers can consistently produce high-quality finishes, making the PostPro SB PRO a must-have tool for firms looking to improve production efficiency.

The PostPro SB PRO stands out for its specialized manual blasting area, which allows operators to clean larger components quickly and efficiently without interfering with the automated blasting process. This adaptability is especially useful for manufacturers who handle a wide range of product sizes and forms, as it allows for quick alterations without extensive reconfiguration. The manual blasting area is ergonomically constructed for easy access and manipulation of parts, allowing workers to work comfortably while maintaining high output. This feature improves operational flexibility while also reducing downtime, allowing manufacturers to respond quickly to changing production demands.

The PostPro SB PRO has a simple user interface that simplifies operation and improves overall user experience. The touchscreen control panel enables operators to quickly browse through many settings and parameters, making it simple to set up and monitor the blasting process. This user-friendly design shortens the training period for new operators, allowing them to quickly become proficient in utilizing the system. Furthermore, real-time monitoring tools give customers with quick feedback on operational status, allowing them to make changes as needed to improve performance. This emphasis on usability boosts productivity and guarantees that manufacturers can effectively manage their post-processing activities.throughout the blasting process.

The PostPro SB PRO promotes environmental sustainability by eliminating the need for hazardous chemical solvents in its functioning. Instead, it only uses mechanical methods for surface cleaning, which greatly reduces hazardous waste formation and simplifies compliance with health and safety laws. This eco-friendly technique meets the expanding industry demand for sustainable manufacturing practices while still producing high-quality products. Mechanical cleaning solutions allow manufacturers to embrace greener practices without sacrificing performance or quality.

The effective dust management system of the PostPro SB PRO, which collects and holds particulate matter produced during operation, is a key component. This solution improves visibility during the finishing process while guaranteeing that the working area stays safe and clean for operators. This feature helps create a healthier work environment and reduces the health hazards connected with airborne particles by reducing dust formation within the chamber. Effective dust control ensures a safer environment for all employees engaged in post-processing operations by increasing operational efficiency and adhering to best standards for workplace safety.

Easy waste removal from the system is made possible by the PostPro SB PRO's quick-clean maintenance features, which were designed with operator convenience in mind. Operators can effectively remove accumulated dust and powder without making a mess or coming into contact with potentially dangerous chemicals thanks to the sealed dust container. By guaranteeing that contaminants are safely contained throughout maintenance procedures, this useful design creates a safer working environment. These quick-clean capabilities enable adherence to health and safety laws in manufacturing environments and improve overall operational efficiency by streamlining waste management procedures. The PostPro SB PRO's ease of maintenance further establishes it as a dependable option for companies seeking to maximize their post-processing capabilities while putting sustainability and safety first.

Fill up the form below and we will send you the data sheet by e-mail.

(This post processing machine has the same data sheet and specifications as the PostPro DP PRO)

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy