3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

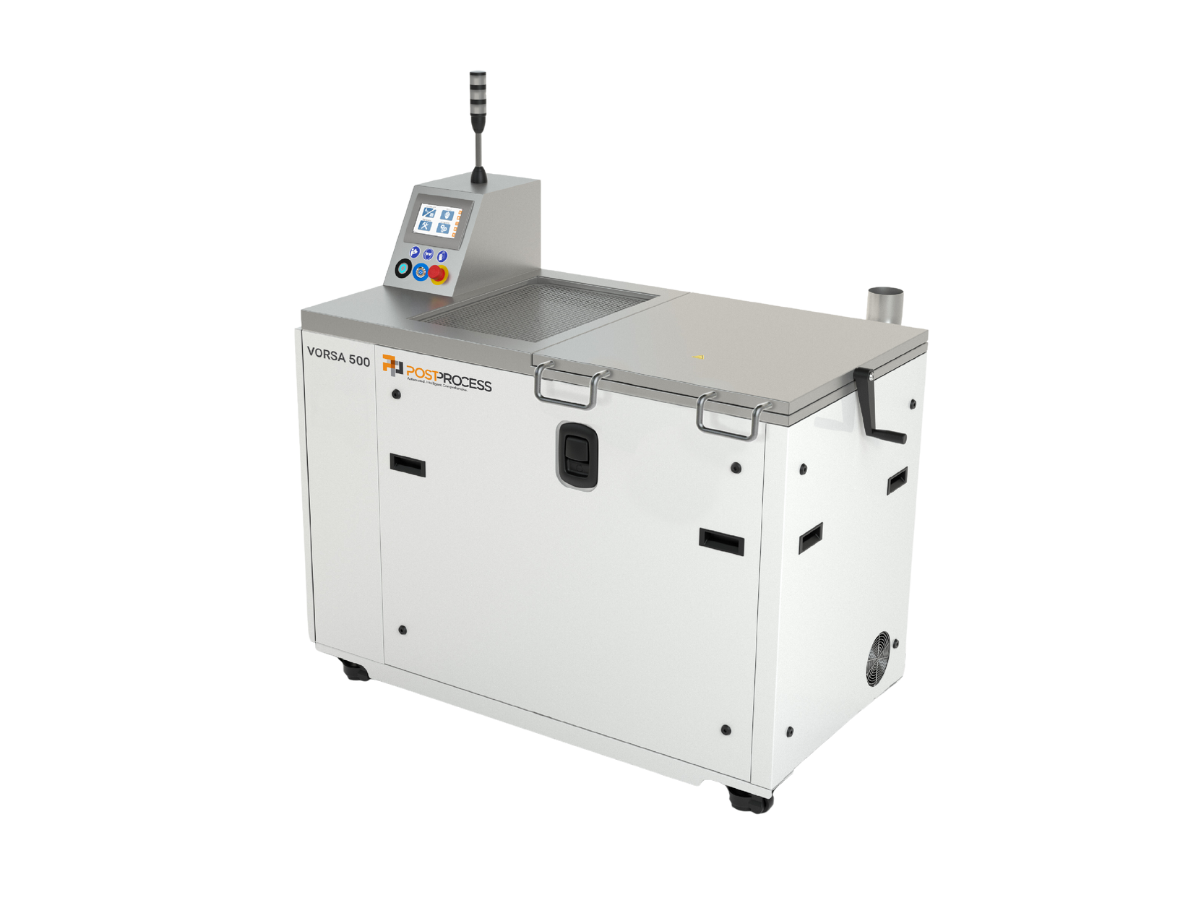

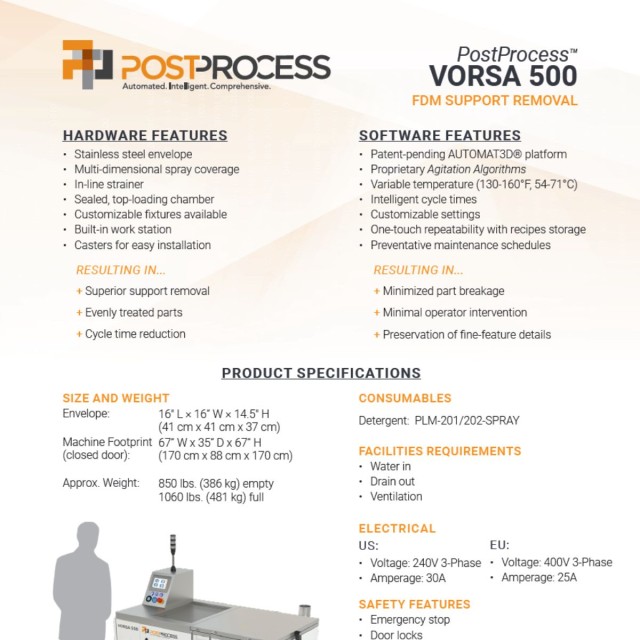

The revolutionary new VORSA™ 500 is a full-stack support removal solution. The VORSA™ 500 is powered by the AUTOMAT3D® software platform and features unique Volumetric Velocity Dispersion technology and game-changing chemistry.

The PostProcess VORSA™ 500 uses the Volumetric Velocity Dispersion (VVD) method to dissolve supports quickly and effectively in a multi-directional spray of detergent. Rather than depending on extensive soak durations, when agitation can knock around sensitive parts and sparse infills might be prone to liquid infiltration, the VVD technique washes away the support material gently and consistently.

The VORSA™ 500 system is completely automated, with pre-programmed and self-programmed recipes tailored to various support types and part geometries. And, it just so happens that its envelope capacity is large enough to accommodate a full-size Stratasys® Fortus® 450mc build.

Technical specifications:

Chamber Size: 410 x 410 x 370 mm

Maximum Liquid Tank Capacity: 98 liters

Variable temperature: 54-71°C

The VORSA™ 500's ample stainless steel chamber size of 410 x 410 x 370 mm enables for a higher throughput of parts to be cleaned during each cycle. Full chamber coverage enables processing bigger batch sizes while delivering consistent, high-quality outcomes for all parts, regardless of geometry.

PostProcess has the industry's quickest cycle speeds (1-2 hours), lowering support removal processing times by more than 50% when compared to submersible tank systems. The VORSA™ 500's multidimensional spray technology allows for exceptionally short dry times while maintaining part integrity because parts are not saturated with detergent.

Fast cycle times with virtually no damaged components are ensured by PostProcess' proprietary Volume Velocity Dispersion (VVD) technology, which consists of a sequence of high volume and velocity jet streams spraying bidirectionally connected with a perpendicular linear motion for mechanically aided support removal. Parts experience a powerful yet gentle, all-encompassing flow of detergent thanks to the high-volume (200 GPM), low-pressure system (35 PSI). The consistent force felt by the part once applied decreases the chance of injuring parts. The portion remains immobile as a result of the bi-directional jetting action, avoiding any potential accidents that a circulation tank could cause.

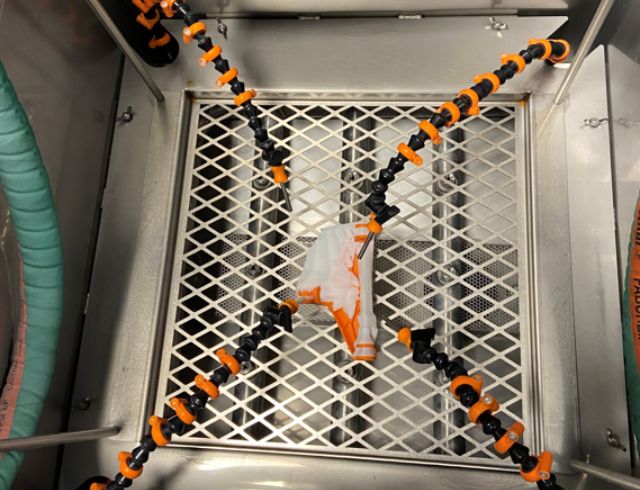

On the VORSA™500, flex nozzles are used to improve support removal rates on internal channels for a limited number of parts. In each corner of the processing chamber, four flex nozzles have been fitted.

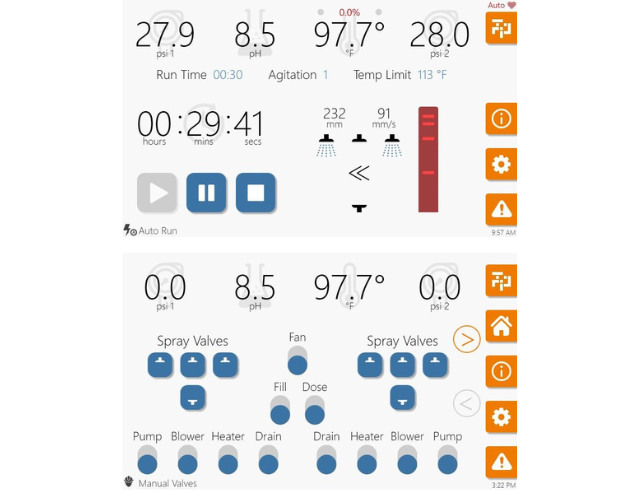

The VORSA™ 500 is intended to be totally autonomous and configured to remove supports, but it can also be operated manually. The pump, blower, heater, and drain valve can be managed independently. When experimenting with new geometries or parameters, manual operation may be recommended.

With pre-programmed formulas, AUTOMAT3D® removes the guesswork from post-printing and lowers operator labor time. The VORSA™ 500 consistently removes FDM support by controlling agitation intensities, temperatures, process times, and more.

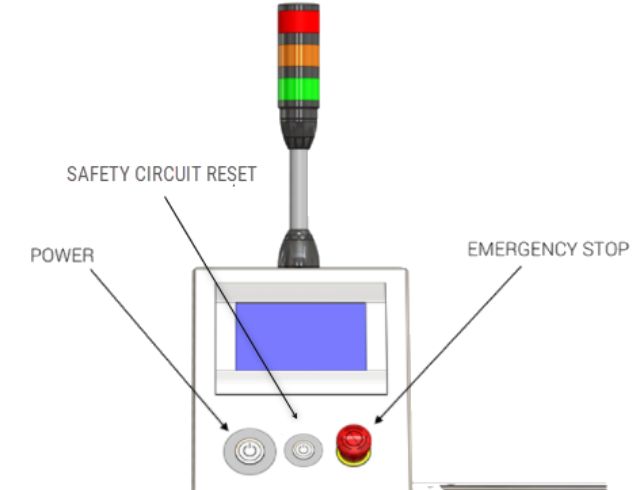

When a warning condition is activated, the system alerts the operator to a problem that must be addressed as soon as possible. It is not necessary to stop the cycle immediately. However, warnings will eventually cause alarms, which must be addressed in order to avoid causing damage to the VORSA™ 500 or your parts. The VORSA™ 500 comes with Low Tank Level, Pressure High and Low, Detergent Life Expired and Tank Temperature Setpoint Exceeded warnings and Emergency Stop, Chamber and Tank Door Open/Lock Failure, Pressure Critically High/Low, Maintenance Due, Dosing Error and Motion Error Alarms among many others.

Fill up the form below and we will send you the data sheet by e-mail:

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy