3D printers

High quality 3D printers

Metal 3D Printing can be divided into two broad groups. First, there are the laser-based printing processes such as Selective Laser Melting (SLM), Electron Beam Melting (EBM) and Direct Metal Laser Sintering (DMLS), as well as the sinter-based processes such as metal FDM 3D printing and Metal Binder jJtting.

The parts resulting from these processes can have undercuts and other very complex geometries that cannot be produced by conventional manufacturing (mechanical / casting).

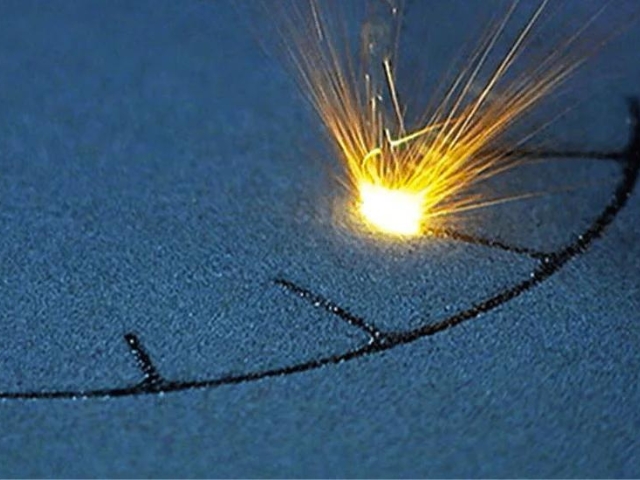

SLM printers, like SLS, use the powder bed melting process to produce objects. The metal powder is gradually melted by a laser to create the desired shape. SLM printers, unlike SLS printers, require support structures. Metals weigh more than the thermoplastics normally printed by SLS machines because they are denser and heavier. Because of the weight of metal, support structures are required to hold the printed parts in place during manufacturing.

In DMLS printing, the metal powder is heated in the pressure chamber just long enough for molecular fusion to occur, but not so long that it melts. The build platform is covered with a thin layer of powder, whereupon the laser selectively sinter each layer of the model. A new layer of powder is applied, the build platform is moved down, and the process is repeated.

In the EBM printing process, conductive metal powder is sintered by means of an electron beam that is guided through electromagnetic coils. After the powder is introduced into the printer, the internal pressure is reduced to create a vacuum. Once the ideal internal pressure is reached, the build platform is heated. Once the build platform reaches the desired temperature, a small layer of powder is applied to the build platform. When the electron beam hits the powder, a reaction occurs that causes the powder to solidify. The electron beam does this for each layer, hitting the powder only at specific locations to build the part.

In Metal Binder Jetting, a thin layer of metal powder is bonded to a print head per layer. The process is also suitable for high volume production and has excellent precision and surface finish.

Metal FDM 3D printing enables the production of metal parts without powder handling and without protective equipment. Thus, high-quality metal parts can be printed in all environments.

CMF printing and Powder Bed Fusion (PBF) printing are relatively similar, but CMF printing requires far less energy because only the binder that holds the powder together is melted, not the metal powder. This increases printing speed and eliminates the need for heat sinks.

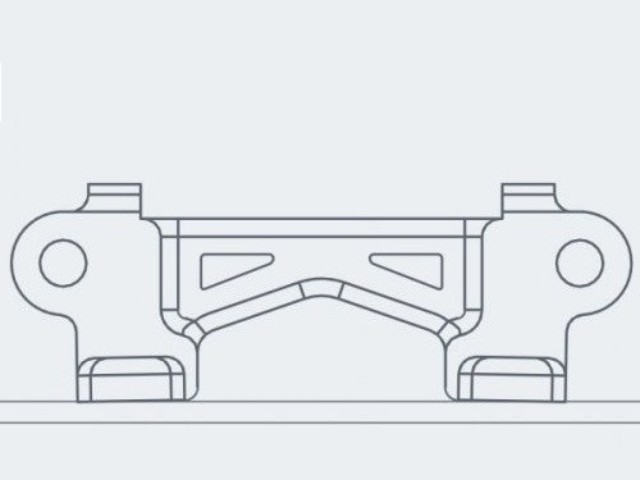

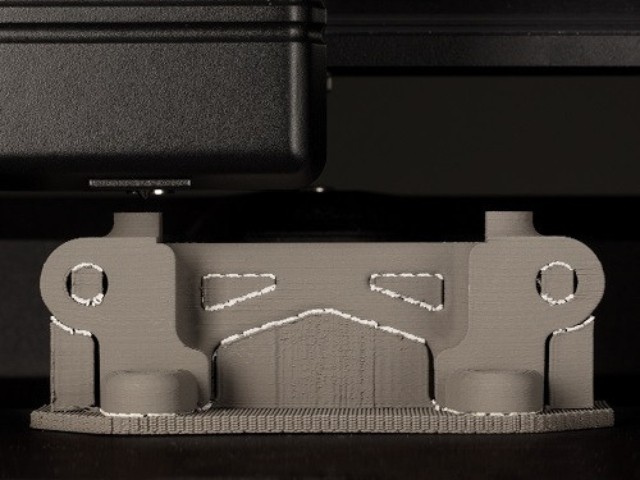

In the first step, the STL or CAD files are transferred to the software. Here, support structures are generated automatically and parameters based on the geometry and material are transferred to the print.

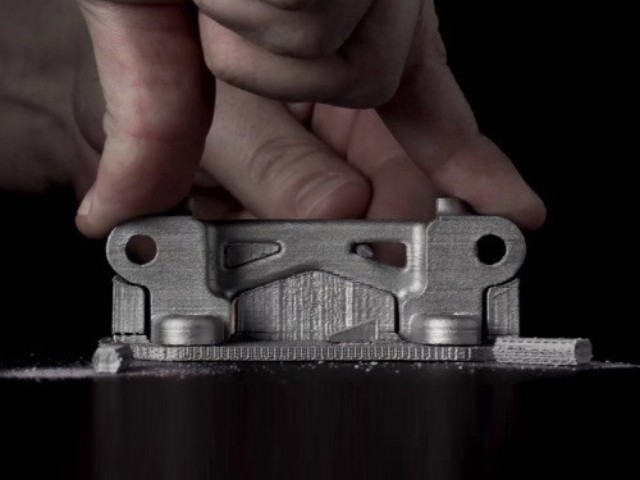

Depending on the sinter-based production technology, the green part is created here either by extrusion or by bonding metal powder. After this step, the component consists of metal powder and bonding agent.

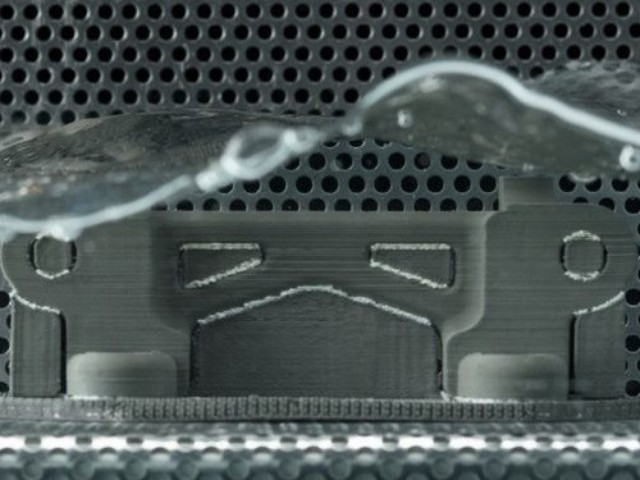

With the aid of the debinding liquid, the primary binder is released from the green part. This creates an open-pored structure throughout the part, which facilitates sintering. (Not all processes require this step.)

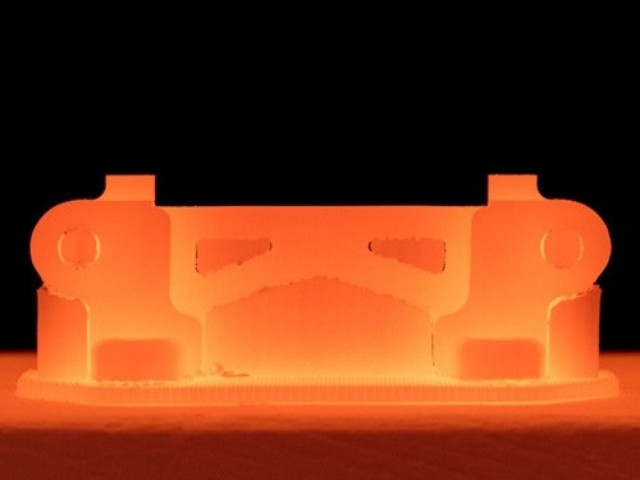

The part is then sintered near the specific temperature, which removes any remaining binder and fuses the metal particles. The finished metal part has a density of approximately 96-99.8%.

While most components can be produced without supports, certain overhangs require a support structure in the sintering furnace. These supports can be removed manually after sintering.

After sintering, the components have a hardness of approx. 250-280HB and can be further processed like a normal semi-finished product.

The production of topology-optimized components, both metal and plastic, can lead to considerable weight savings in the aerospace sector. For example, cabin components are already being manufactured additively in small batches.

In the automotive industry, metal 3D printing is used in particular for prototyping and series production. Prototype vehicles and pre-series models can be realized in a very short time. In addition, complex components can be printed in high quantities.

With countless applications in medical industry, metal 3D printing is used here for tools, implants and surgical aids, among other things. Due to the mostly small quantities, metal 3D printing is particularly important here.

Consumer product manufacturers can use metal 3D printing for rapid prototyping and testing of new designs to verify functionality and market feedback. As a flexible production line for low-volume and regionally customized products that allow greater design freedom for product customization, this process has also proven its worth.

For companies that does tooling, 3D printing can be an invaluable resource, enabling the rapid and cost-effective production of complex custom tooling and the easy replacement of tools as needed, reducing production line downtime.

By investing in metal 3D printing, educational institutions can give their students the tools to bring their work to life and help them gain important job skills.

Our team of experts supports you in the selection of materials and finds the suitable process with the optimum hardware solution for the application.

We will be happy to advise you on which material and which manufacturing process is suitable for your application. Depending on the process, materials such as stainless steel, copper, titanium, carbide, Inconel and all Ni-based alloys can be processed.