3D printers

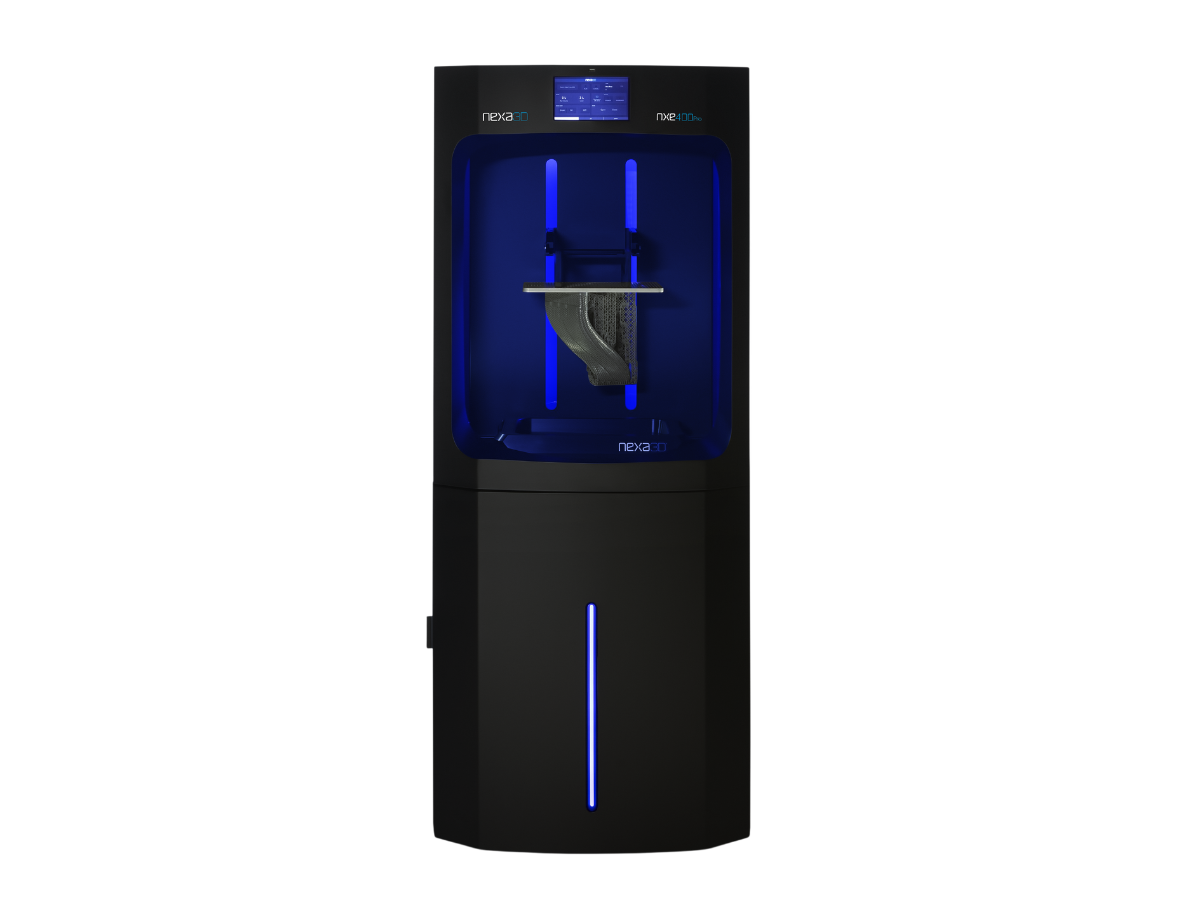

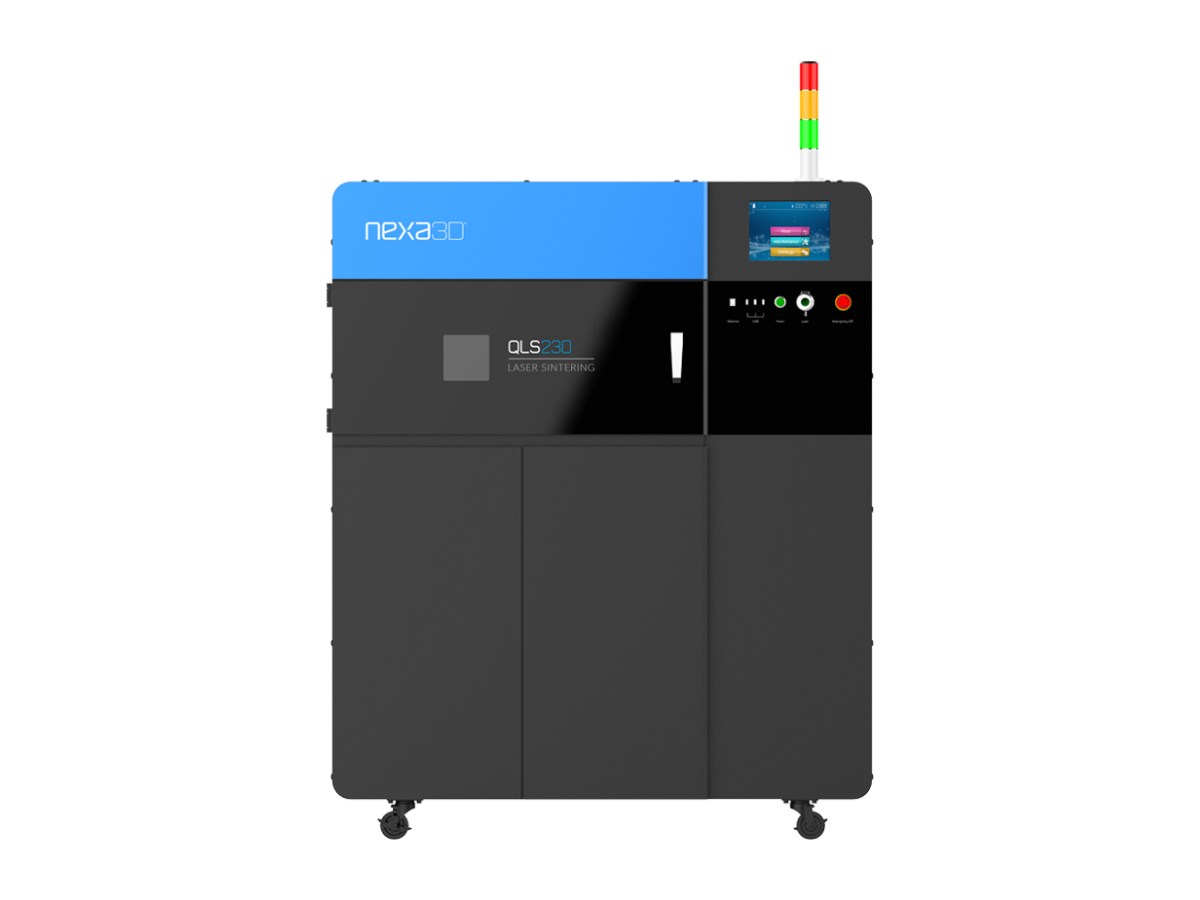

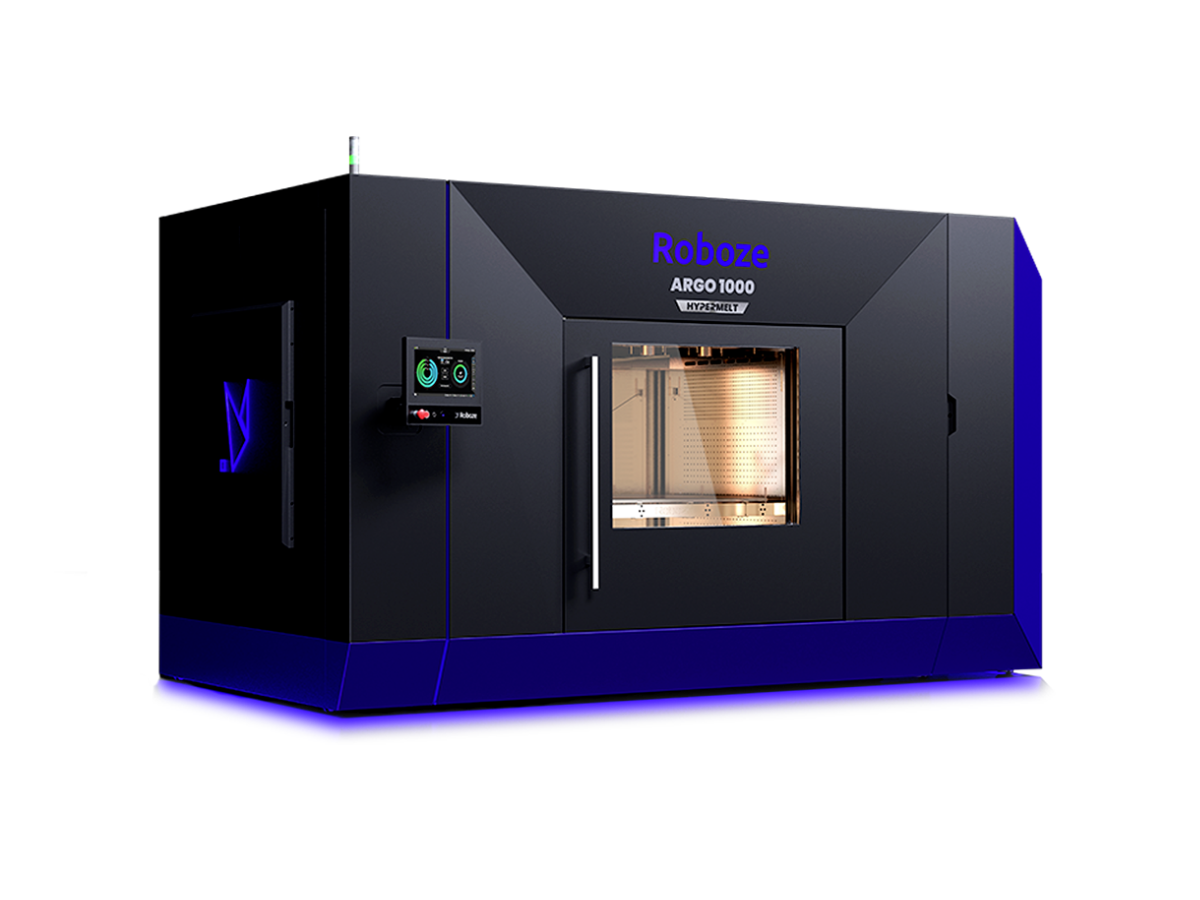

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send EmailWhile 3D printing was previously used primarily for prototyping, the new 3D production systems are finding more and more applications in series production. Newly developed 3D printers and printing materials now enable the production of hundreds of thousands of components. Additive series production increases flexibility in the manufacturing process and makes it possible to make customer-specific adjustments. No investment in an injection mold is necessary, thus the capital investment for new products can be greatly reduced.

The first step is a technical evaluation of your CAD data by one of our application engineers. In this step we discuss your application and the requirements and make a pre-selection of the printing material and the printing technology.

Before carrying out the test print, we will provide you with a cost and time calculation. Possible post-processing steps can be calculated and discussed here. Together we validate the commercial side of your project in this step.

In the third step, we produce some sample parts for you. You can then use the parts to validate the technical aspects of the project and perform all the necessary tests. A production system can then be installed at your site.

Due to the wide range of materials available for the various 3D printing processes, we can find a suitable material for almost any application. We will be happy to advise you on which material is suitable for your production.

Here you will find a short selection of potential materials:

Resin, ABS, PC, PEEK, PA12, PA11, PA6, PBT, PP, TPU, Carbon Fiber, Ultem, ...

Good mechanical properties, excellent precision, clean surfaces.

High complexity possible, very stable components, good heat resistance.

Cost-effective alternative, wide range of materials, simple process.

Cost-effective alternative, wide range of materials, simple process.

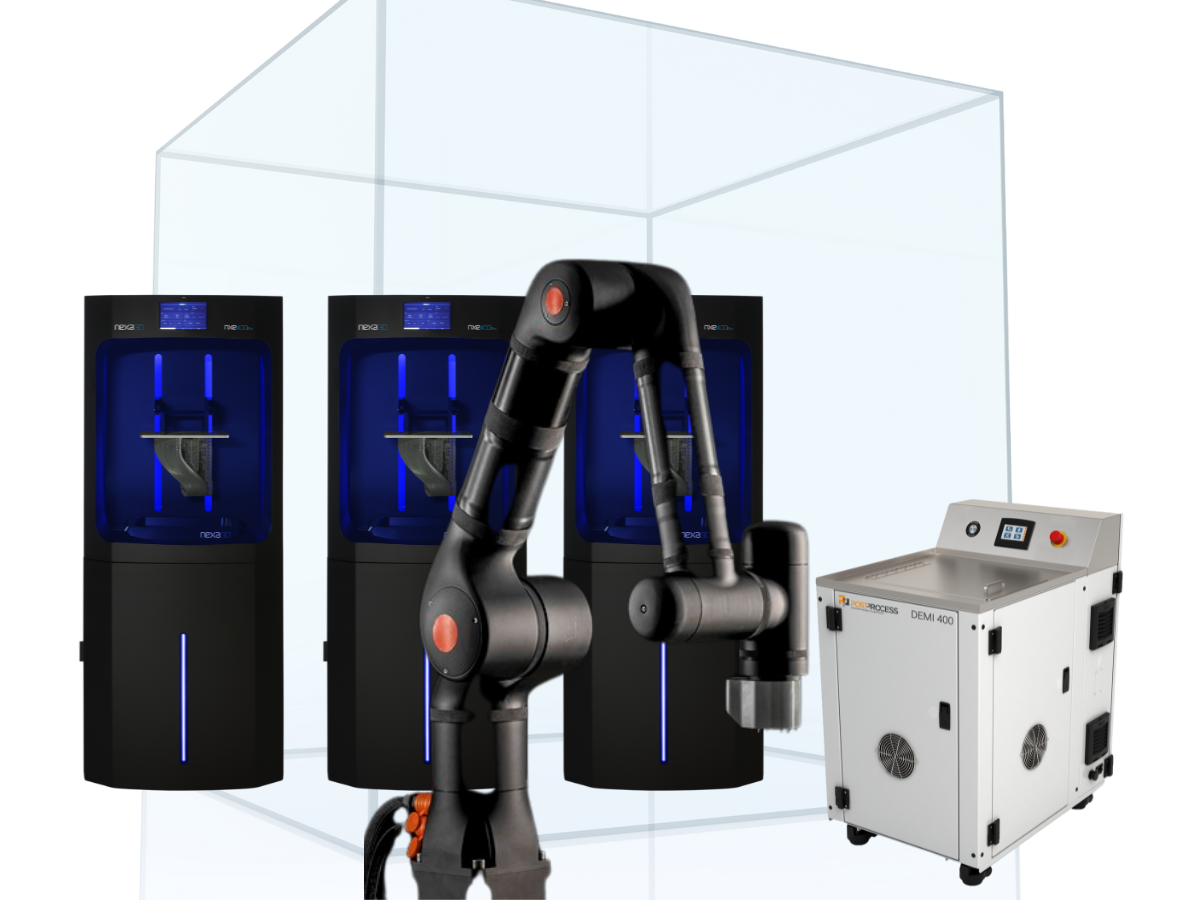

Fully automated production cell for series production of 3D printed components.

We supply fully automated production systems for the series production of your product. Using the latest automation technology, we increase production capacity while reducing the cost per part.

Contact us for more information!

Our team of experts, especially our application specialists, will support your project in all individual steps. Together with our software team, we also have the possibility to accompany you during the design process to optimize the components for 3D printing.

Do you have an interesting application?

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy