3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

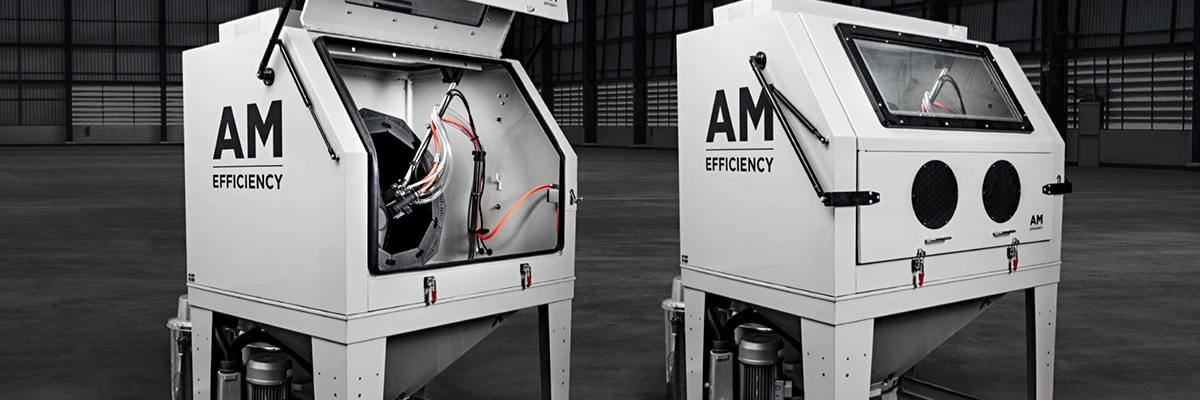

AM Efficiency, based in Västervik, was founded in Sweden in 2019 by Ulf Qviberg. The Swedish company offers several solutions for the post-processing of powder-based components, all of which feature a high degree of automation and outstanding results.

With over 15 years of experience in 3D printing, Qviberg had become familiar with a variety of technologies. He had noticed that, especially with powder-based printing processes, different machines always had to be used for the comparatively large number of post-processing steps, which was associated with high costs, a lot of space and increased workload.

AM Efficiency's systems solve all these problems. The CCP series combines three processes – cleaning, polishing and coloring – in a compact system, and the brand-new UNPIT, which has been specially developed for entry-level SLS systems, takes care of unpacking, de-powdering and cleaning components, while also ensuring improved material recovery management to optimize recycling and thus protect the environment and save money.

We also recognized the difficulties in the post-processing of powder-based components early on and the partnership with AM Efficiency was therefore an easy decision for us after we were convinced of the extraordinary efficiency of their systems.

Together with AM Efficiency, we continue to work on new solutions that will make the post-processing of powder components even faster, more efficient and easier, while also improving powder recovery, in order to move a good deal closer to our vision of more climate-friendly production.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy