3D printers

High quality 3D printers

When you think of 3D printing, the first thing that usually comes to mind is an FDM printer that extrudes material layer by layer, but that's not the only way to make something three-dimensional. 3D Polymer Powder Printing is another popular additive manufacturing process. Unlike FDM Printing, which uses filaments, the primary printing medium in Polymer Powder 3D Printing is a polymer powder.

Selective Laser Sintering (SLS) and Binder Jetting are the two sub-technologies that make up Polymer Powder 3D Printing.

In SLS Printing, the powder is placed in the printer's powder hopper and heated to a temperature just below its melting point. When the correct temperature is reached, the build platform is covered with a thin layer of powder.

The powder layer is then selectively sintered based on the model using a CO2 laser or IR laser. Once the layer is applied, the build platform moves down and the recoater applies another powder layer. The new layer is sintered with the laser. This process continues until the desired object is finished.

The build plate is covered with a thin layer of powder, just like other powder printing processes. Instead of fusing the material via the influence of heat, as in other processes, a print head moves over the surface and virtually sprays on a binder. The powder becomes solid when the liquid comes into contact with it. The build platform moves down as each layer is completed, the recoater applies another layer of powder to the build surface, and the cycle repeats until the part is finished.

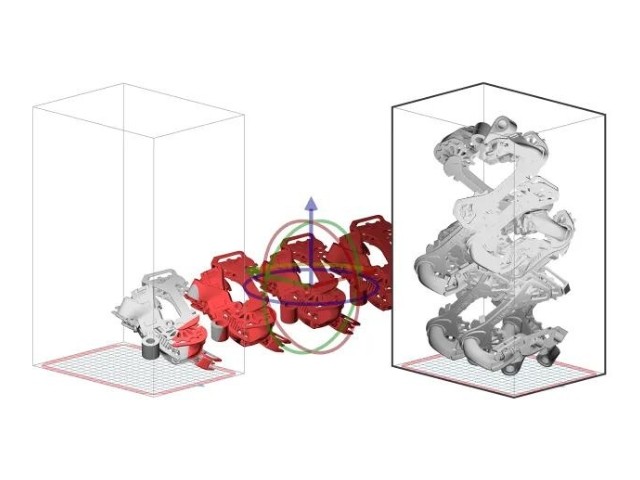

The first step involves preparing the print data with a selected CAD or 3D printer software. Subsequently, the prepared data is transferred to the 3D printer and processed.

Before a print is carried out, a sufficient and reliable supply of material is ensured. This is done by first checking that there is sufficient material available for printing, then agitating the material in the feed to remove any air that may be present.

In the third step, the actual printing of the component takes place. In a step-by-step process, the material is sintered by means of a laser beam and the desired component geometry is formed.

After the print job has cooled down, the excess powder is removed from the components. The excess powder is then reprocessed and used for the next print job.

Sandblasting the components creates a uniform and high-quality surface structure and refines the component. In addition, sandblasting ensures that there is no powder left on the components.

The components can be further processed afterwards. The components can be colored or mechanically processed, for example.

By manufacturing components with complex geometries using the Selective Laser Sintering process, considerable weight can be saved in the aerospace sector. Examples include cabin components such as ventilation grilles, which are produced in small batches using SLS.

In the automotive industry, Selective Laser Sintering is used in particular for prototyping. Prototype vehicles and pre-series models can be produced in a very short time. Both exterior elements and interior components are manufactured.

The SLS process is increasingly being used both in apparatus engineering and in prosthetics. Due to the small quantities required as well as high demands on precision and material, Selective Laser Sintering is ideally suited.

Similar to aerospace, there is a need for powder-based 3D-printed components in the defense industry, as they help reduce weight and consolidate the number of parts and designs, leading to greater efficiency.

Although 3D Powder Technology is primarily used for professional rapid prototyping, it is also playing an increasingly important role in the production of small batches and spare parts. The replacement of injection molded parts is also becoming possible.

Because of its low cost per part and durable materials, SLS 3D Printing is an economical way to produce complex, custom parts or a series of small components for end products.

Our team of experts will be happy to support you in choosing the right 3D printing technology and in selecting the right 3D printing system.

Our application team also advises you on the choice of materials. Among other things, we can provide cost and time calculations as well as sample parts. In our showroom we have the possibility to validate the project together with you!