3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

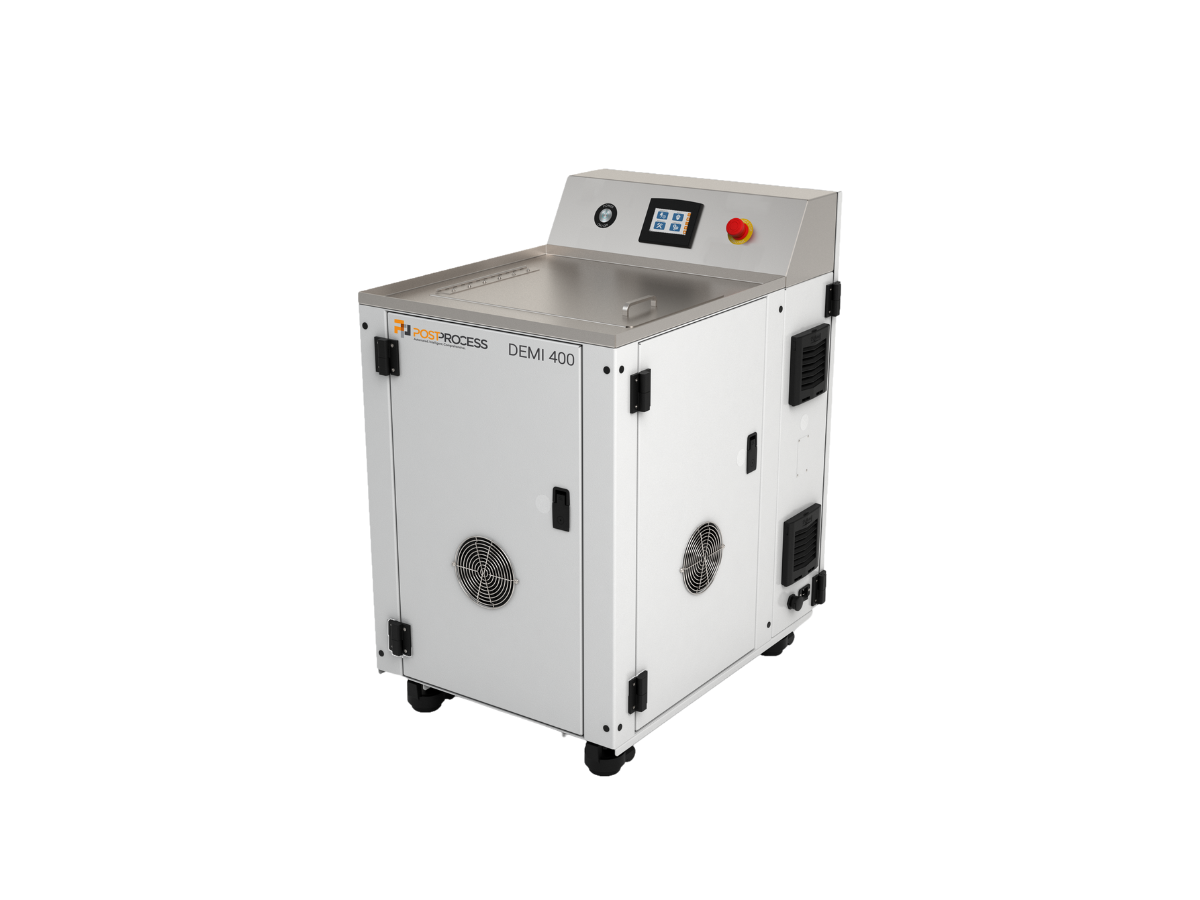

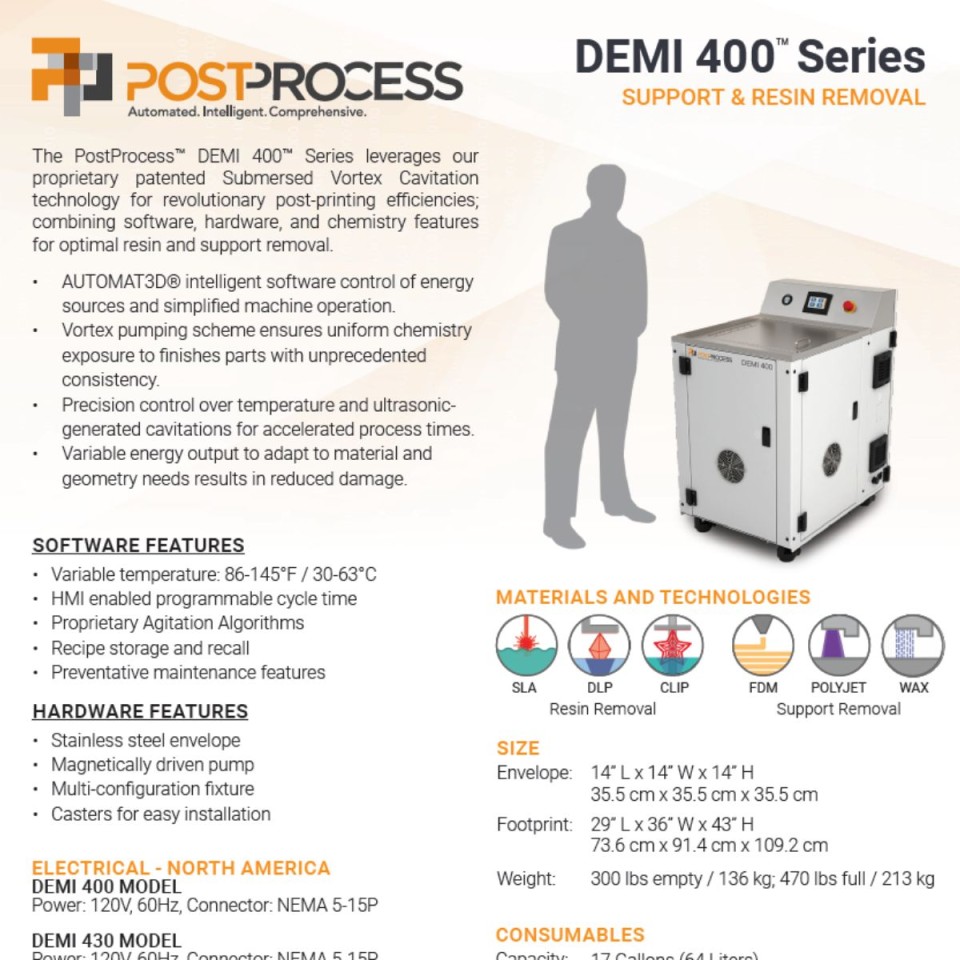

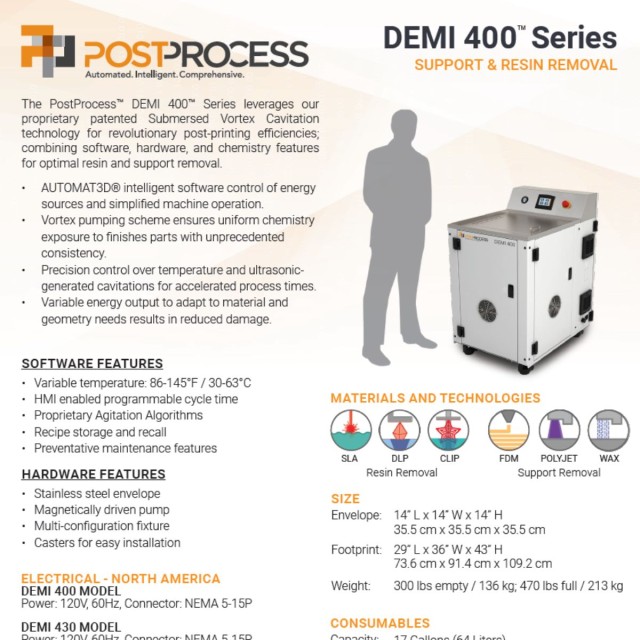

For SLA, CLIP and DLP technologies, the PostProcess™ DEMI 400™ Support & Resin Removal Submersion Device enables automatic removal of PolyJet and FDM supports and excess resin.

PostProcess Technologies' Submersed Vortex Cavitation (SVC) technology is already integrated in the DEMI 400 version to ensure a uniform cleaning effect.

The DEMI 400 provides a precise, automated post-process solution for additive manufacturing operations.

A uniquely,e software-controlled process control in conjunction with special cleaning agents, ensures highly efficient cleaning of components.

Technical data:

Basin size: 355 x 355 x 355 mm.

Capacity for consumables: 64 liters

Variable temperature: 30-63°C

PostProcess SVC solutions use a sophisticated pumping system to rotate the part while it is immersed in the cleaning agent. The vortex component of SVC technology ensures that the part is uniformly exposed to the cleaning agent and cavitation from the ultrasound, regardless of density or geometry and its effect on the buoyancy of the part.

PostProcess uses cavitation generated by ultrasound as an additional source of mechanical energy to improve cleaning. The ultrasound creates compression and expansion waves in the cleaning fluid by emitting sound waves with varying frequencies and amplitudes. On the surface of the part, the movement of the liquid causes cavitation and the formation of small bubbles. As the substrate is weakened by the chemical, these bubbles agitate it, accelerating the reaction.

Post Process' unique chemistry is a key factor in the effectiveness of SVC technology.

The three main cleaning agents in the SVC line were all developed by Ph.D. chemists specifically for cleaning additive materials.

Here, each printing process has its own special cleaning agents, which have been optimized for the materials used.

PostProcess cleaning solutions dissolve the substrate or uncured resin for each of these technologies without damaging the build material.

.

In a conventional system, the carrier material disintegrates and falls to the bottom of the machine. The efficiency of the shaft generated by the converter would then be compromised by this deposited material. By placing them on the side of the machine, PostProcess SVC machines have reduced this problem and ensured optimal efficiency throughout the cycle.

The purging algorithm, which carefully controls the energy, speed and direction of the system, ensures that the cleaning time is minimized.

The AUTOMAT3D software varies the rinsing intensity, temperature and process time to achieve ideal cleaning in the shortest possible time.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy