3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Nexa3D®'s QLS 236 uses selective laser sintering (SLS) technology to produce parts with excellent mechanical and thermal properties. The system can also produce highly complex components without support structures.

The QLS 236 is the ideal system for all users who require high-quality components at low prices. Nexa3D®'s SLS system offers higher speed and access to BASF's highest-performance SLS materials and an open material platform. The industrial SLS system impresses with a powerful CO2 laser and a large installation space.

Key points:

Technology: SLS (selective laser sintering).

Usable build volume: 230 x 230 x 250 mm

Laser power: 60W CO2

Max. Printing speed: up to 22 mm/hour

A print speed of up to 22 mm per hour is possible with the QLS 236. This makes the printer perfect for the production of prototypes and small series.

Together with the high printing speed, the system has a shorter cooling time compared to other SLS machines, allowing for higher throughput while still delivering high-quality parts with optimal mechanical properties.

The QLS 236 is equipped with a 60-watt CO2 laser and has a usable build volume of 230 x 230 x 250 mm. With a more powerful laser compared to the Nexa3D® QLS 230 twice the scanning speed can be achieved.

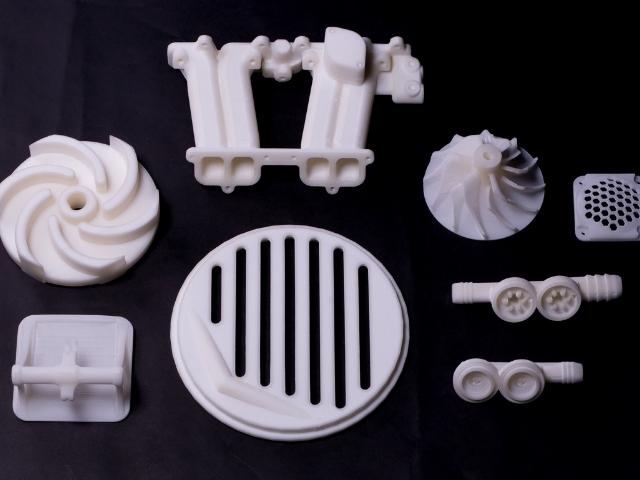

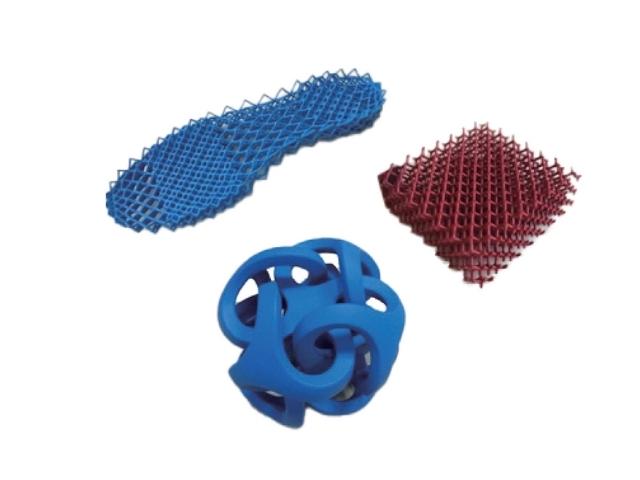

When using SLS technology, it is not necessary to print additional supports, as the thermoplastic serves as the support material. As a result, the printing process conserves resources and the print result is not compromised. In addition, many models can be stacked and printed in any orientation. This increases productivity and reduces parts costs.

The Nexa3D® QLS 236 has 6 thermal panels and its build chamber can reach temperatures of up to 220 degrees Celsius.

The modular print chamber module of the Nexa3D® QLS 236 enables effective use. You can remove the finished print job from the printer and let it cool down in the post-processing station. The removable recycling bin also makes it easy to reuse the powder.

Buildware and Nexa3Dprint® (XYZprint) AM SLS are two software programs used by the QLS 236. Buildware gives the user the ability to start the job and adjust the settings directly at the printer. Scheduling of projects and print processes as well as monitoring of running print jobs is made possible by Nexa3Dprint® (XYZprint) AM SLS.

Cold Metal Fusion from Headmade Materials® is a patented process that combines the advantages of rapid sintering with established powder metallurgy processes for the production of titanium and steel parts. Using a polymer-coated metal powder, the QLS 236 produces "green" parts in a low-temperature processing environment. The parts then go through a secondary debinding and sintering process that burns out any residual polymer and sinters the metal particles together to form the final metal components.

Rapid prototyping and low-volume applications can now be used at higher temperatures thanks to the Nexa3D® QLS 236 with polyamide 6 powder, which is particularly advantageous in the automotive and electronics industries.

To always find the ideal material for components and models, the Nexa3D® QLS 236 can use a wide range of materials. In addition, custom material profiles can be created for special applications and for new materials.

Series components that can even replace injection molded parts.

Produce complex objects quickly and cost-effectively.

HP Multi Jet Fusion technology limits the recyclability of powder material. Once the limit is reached, the powder is end-of-life and can no longer be used. This means HP MJF customers must dispose of large quantities of powder. Now, this end-of-life powder can be recycled and printed on XYZprinting SLS printers. In addition, this powder can be easily mixed with as little as 5% fresh PA12 powder for brighter parts.

Test form, fit, and function with an accurate representation of the final product.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy