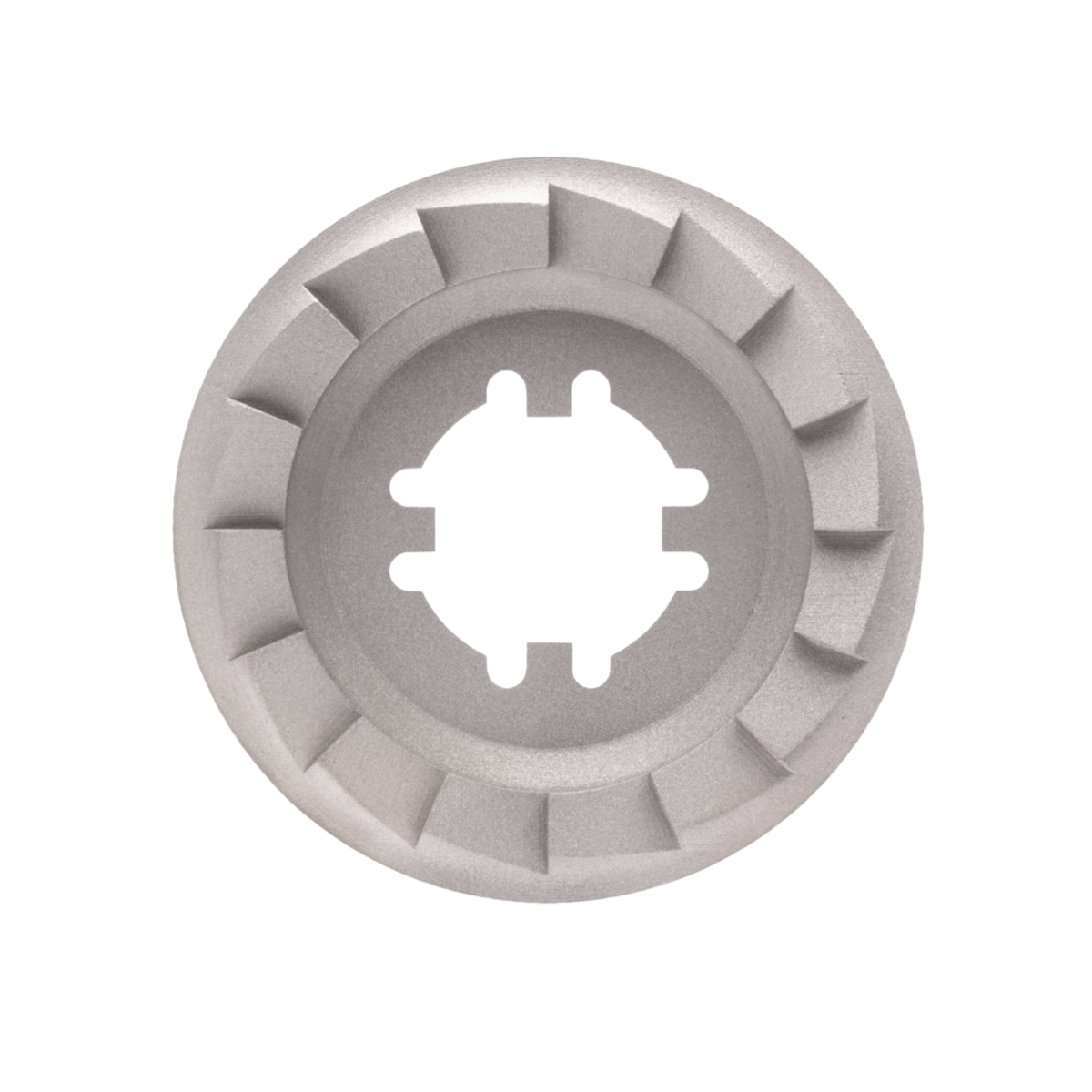

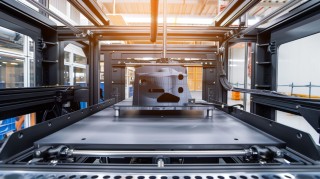

Your 3D printing service provider for professional and industrial components!

With our ISO 9001 certification in the areas of consulting, services and production of additively printed 3D components and our engineering expertise in resin, filament, powder and metal technologies, we are the ideal partner for your 3D printed components.

-

Production times of 1-4 days with next day shipping option

-

Affordable pricing

-

Dedicated material and process development team

-

Master service agreements possible

Over 80 industrial 3D-printers

SLA, DLP, High Temperature FDM

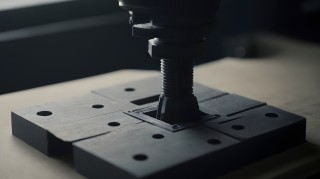

Painting, assembling, threading, vibratory grinding, coating, milling of functional surfaces, dying, chemical smoothing, etc.

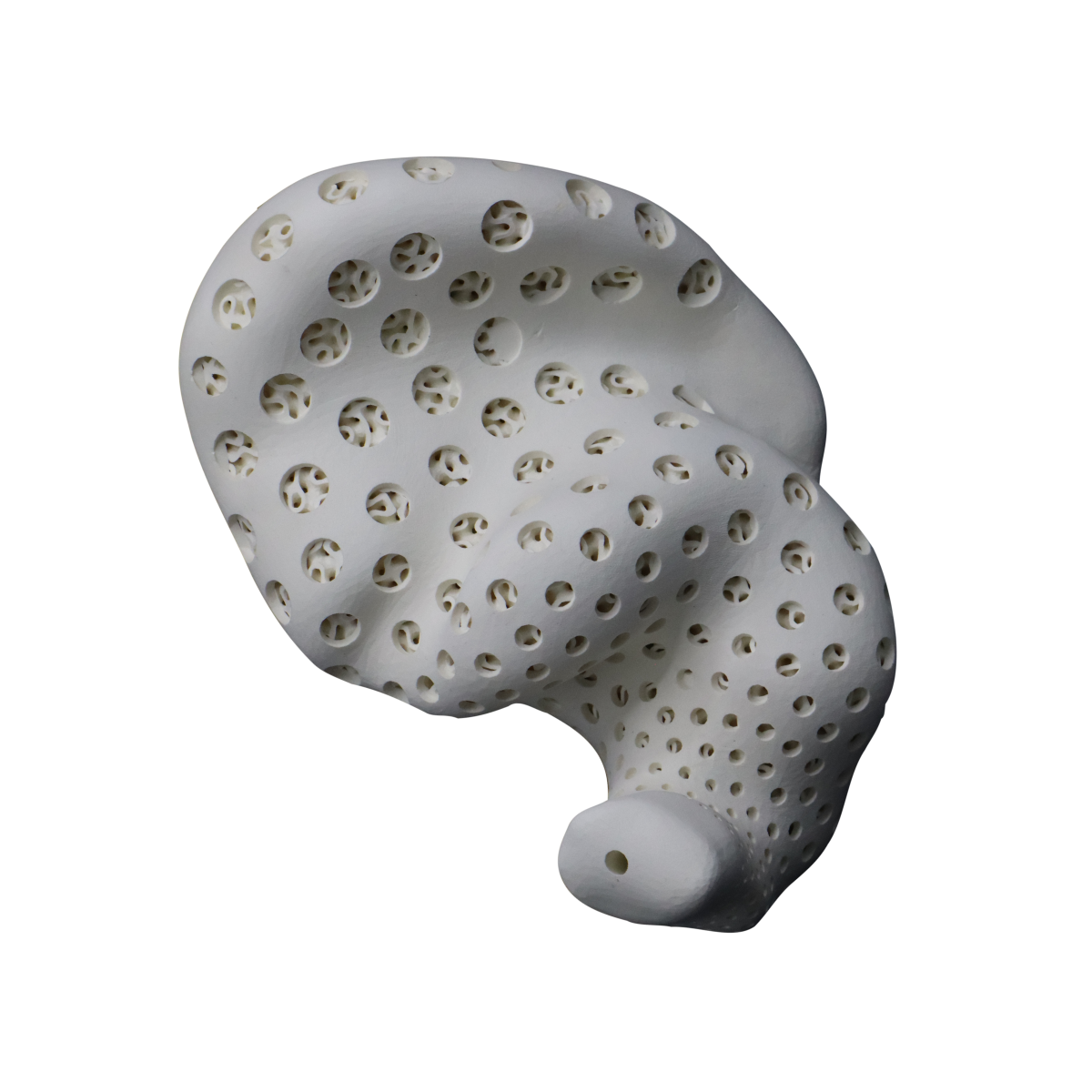

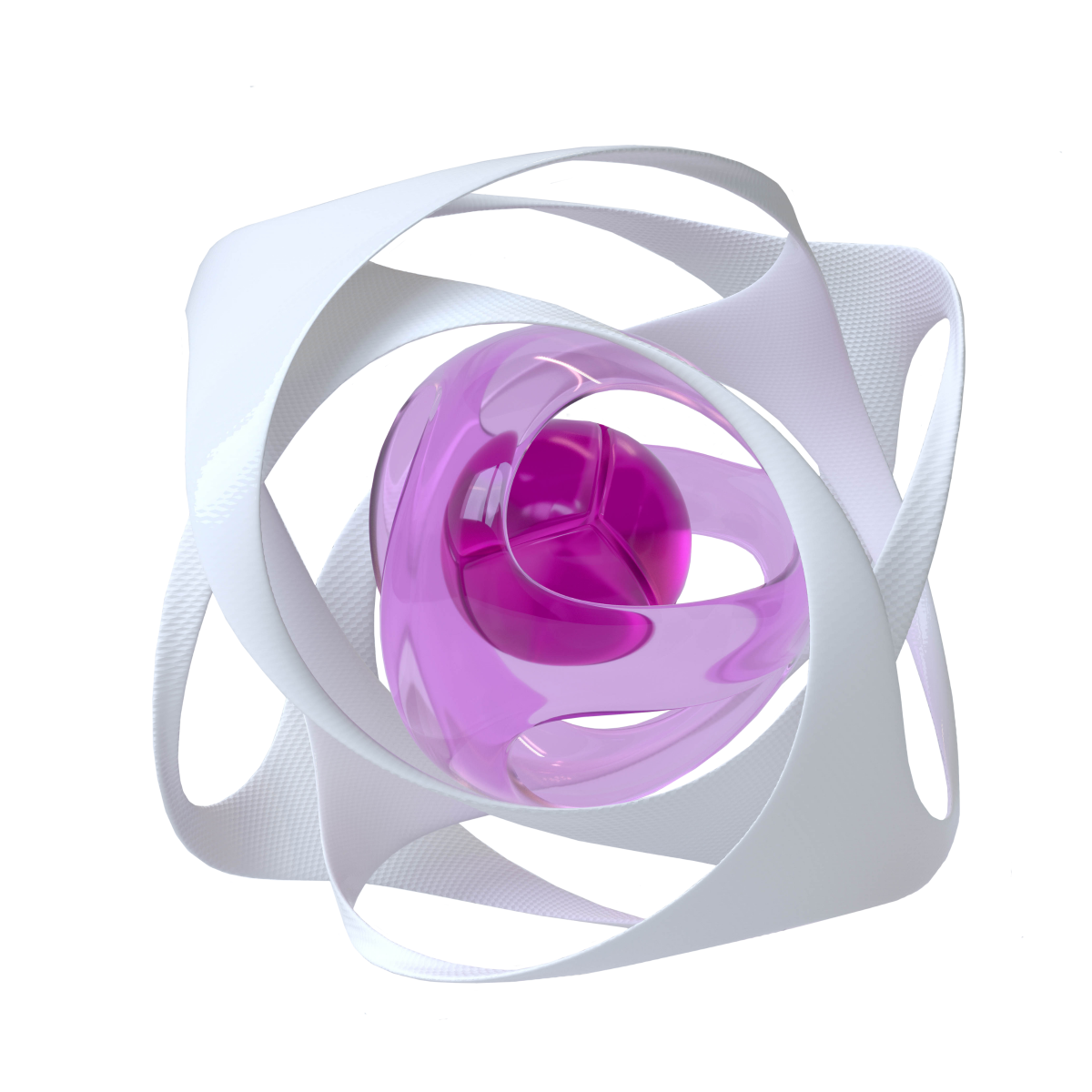

From very small to very large parts of up to 1,000 x 1,000 x 1,000 mm

Over 100 materials available

Has over 70 leading 3D printing experts in PTG group

Customer Journey Towards Additive Manufacturing

PartsToGo’s and ProductionToGo's combined mission is to expedite and safeguard the process of developing applications for additive manufacturing (AM). We provide tailored guidance to each client, empowering them to forge their unique path toward progress in this innovative domain.

PartsToGo is one of the largest 3D printing service bureaus in Europe, offering comprehensive 3D printing services to meet diverse production needs.

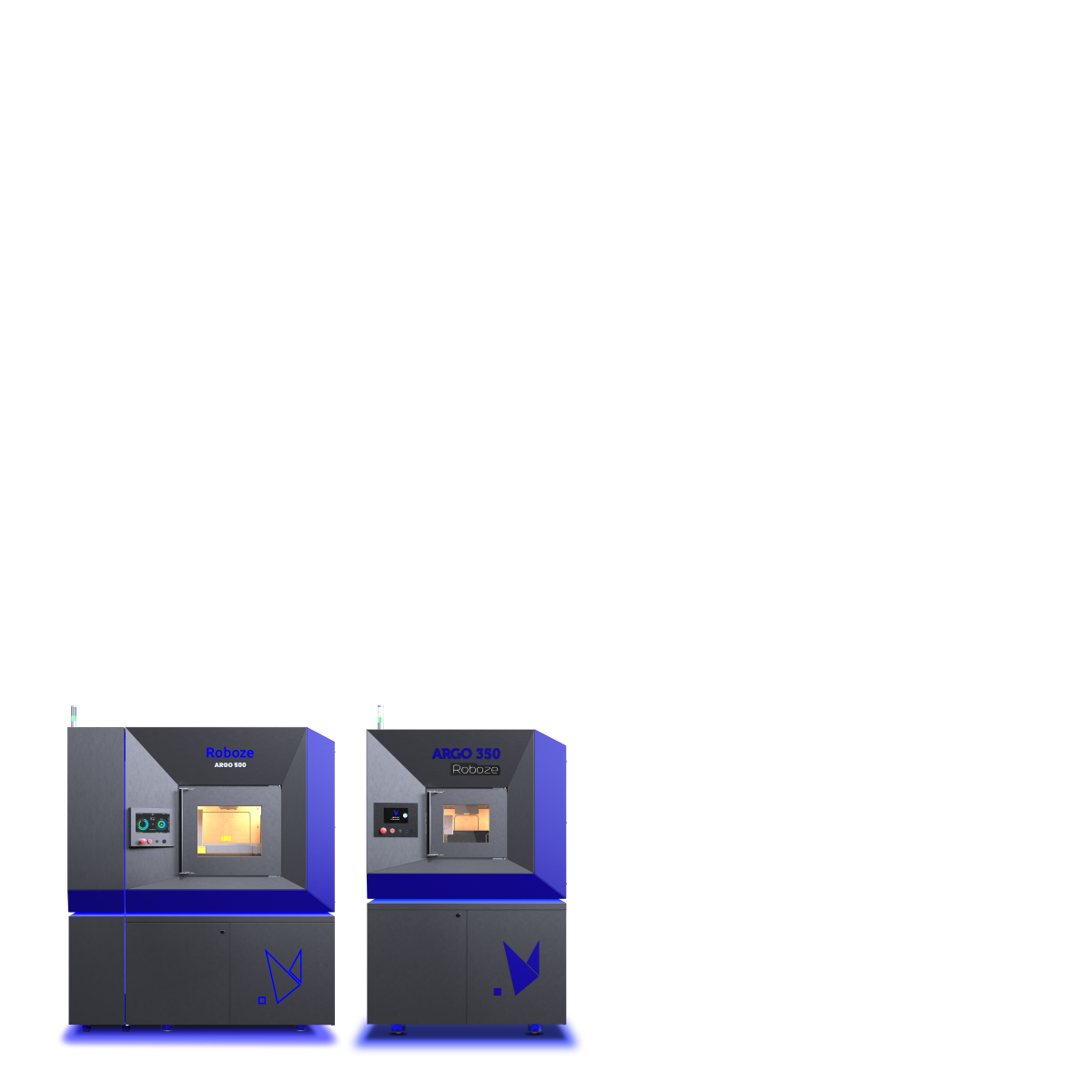

ProductionToGo is one of the largest certified 3D printing reseller of world-class industrial and desktop 3D printing solutions across Europe.

- 1

- 2

- 3

- 4

- 5

-

1 - 2 Days

Application Screening

We discuss your project needs and expectations while evaluating its 3D printability.

- DISCUSS CUSTOMER NEEDS AND EXPECTATIONS

- CONDUCT PRINCIPAL AM FEASIBILITY EVALUATIONS

- INTRODUCE POSSIBILITIES AND TECHNOLOGIES

-

30 - 90 Days

Application Development

We work together to consolidate quality and performance expectations, define the required 3D printing technology and material, and develop the necessary processes.

- CONSOLIDATE QUALITY AND PERFORMANCE EXPECTATIONS INTO KPIS

- DEFINE TECHNOLOGY AND MATERIALS

- DEVELOP PROCESSES

-

7 - 14 Days

Application Verification

We create benchmark parts and optimize processes through KPI analysis, show proof of capability and establish total cost of ownership (TCO).

- CREATE 3D PRINTED BENCHMARK PARTS VIA PARTSTOGO.

- OPTIMIZE PROCESSES WITH KPI ANALYSIS ON ALL LEVELS (DESIGN, TECHNOLOGY, MATERIAL).

- ESTABLISH PROOF OF CAPABILITY AND TCO.

-

30 - 60 Days

Pilot Production

We run the first production sequence to validate part properties and come to a point where you decide to either make or buy.

- RUN FIRST PRODUCTION SEQUENCE

- PROVE MANUFACTURING CAPABILITY

- PREPARE SUPPLY CHAIN INTEGRATION TO MAKE OR BUY

-

30 - 180 Days

Supply Chain Integration

Purchase Parts via PartsToGo:

- DEFINE QUALITY THROUGH REQUIREMENTS AND FUNCTIONAL SPECIFICATIONS

- PROVIDE CLEAR COST AND TIME STRUCTURES

- MANAGE PART PRODUCTION AND DELIVERY

AND / OROwn the process via ProductionToGo:

- INTEGRATE AM PROCESSES INTO EXISTING STRUCTURES.

- DESIGN, PREPARE, AND OPERATE GUIDELINES.

- IMPLEMENT PROCESS BEST PRACTICES WITH MULTILEVEL AND INDIVIDUAL SKILLSET TRAINING.

- CONDUCT ONGOING OPERATIONS

Gain a competitive edge by understanding the transformative impact of 3D printing across diverse applications.

Understand the properties you need for your parts.

Certified Quality Control

-

ISO9001 certification

-

Quality assurance check of every component

-

Advanced quality assurance possible if required

-

Scanning and advanced mechanical testing possible

-

Over 70 leading 3d printing experts in PTG group

-

Dedicated material and process development team

-

Experienced application engineers for the most complex projects