3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

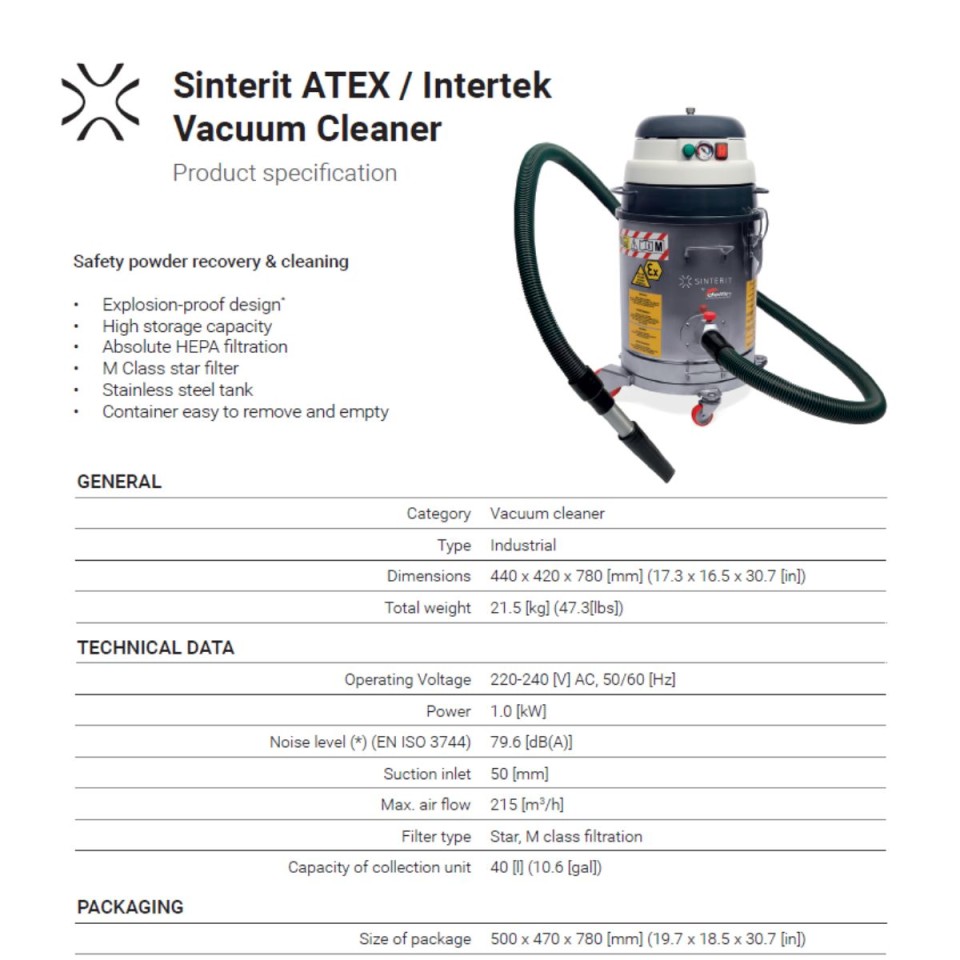

Supporting tool designed for the cleanest possible powder recovery.

When processing powders for selective laser sintering, the Sinterit ATEX-compliant vacuum cleaner for plastic dust ensures an ideal workflow. With the associated cyclone separator, the powder can be collected, which is then mixed in the powder sieve or prepared for the subsequent printing process.

With the two nozzles, the floor and, if necessary, the work surfaces can be cleared of dust deposits. Explosion protection is provided for the exhaust system.

Technical data:

Suction opening: 50 mm

Maximum air flow rate: 215 m3/h

Filter type: star, M-class filtration

Collector capacity: 40 liters

Certification: ATEX Z22 / NRTL D2C2

Clean your printer in ten minutes and collect powder residues. Reduce costs and time. In less than 10 minutes, your printer is ready for the next print. Use the Sinterit ATEX vacuum with powder separator to quickly produce unsintered powder for the next print in addition to cleaning tasks.

Reduce your workload by using a single device to collect powder and clean your workplace. The Sinterit separator automatically conveys the collected powder into the designated container without human intervention. Then you can simply pour the powder into the Sinterit Sieve. Alternatively, you can secure the container and store the powder for later use.

Clean your desk with the ATEX Vacuum in a few easy steps. Recover 100% of your powder and clean up your office. The powder spilled while cleaning the prints can be picked up by the ATEX Vacuum both from the workshop and from the surface of the prints. And it's completely safe to do so.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy