3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

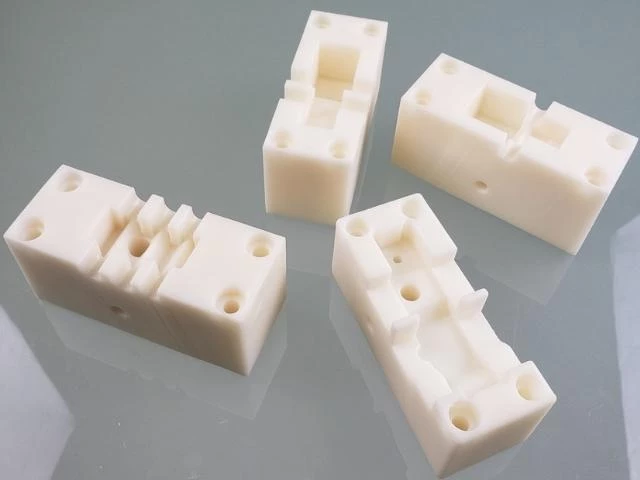

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

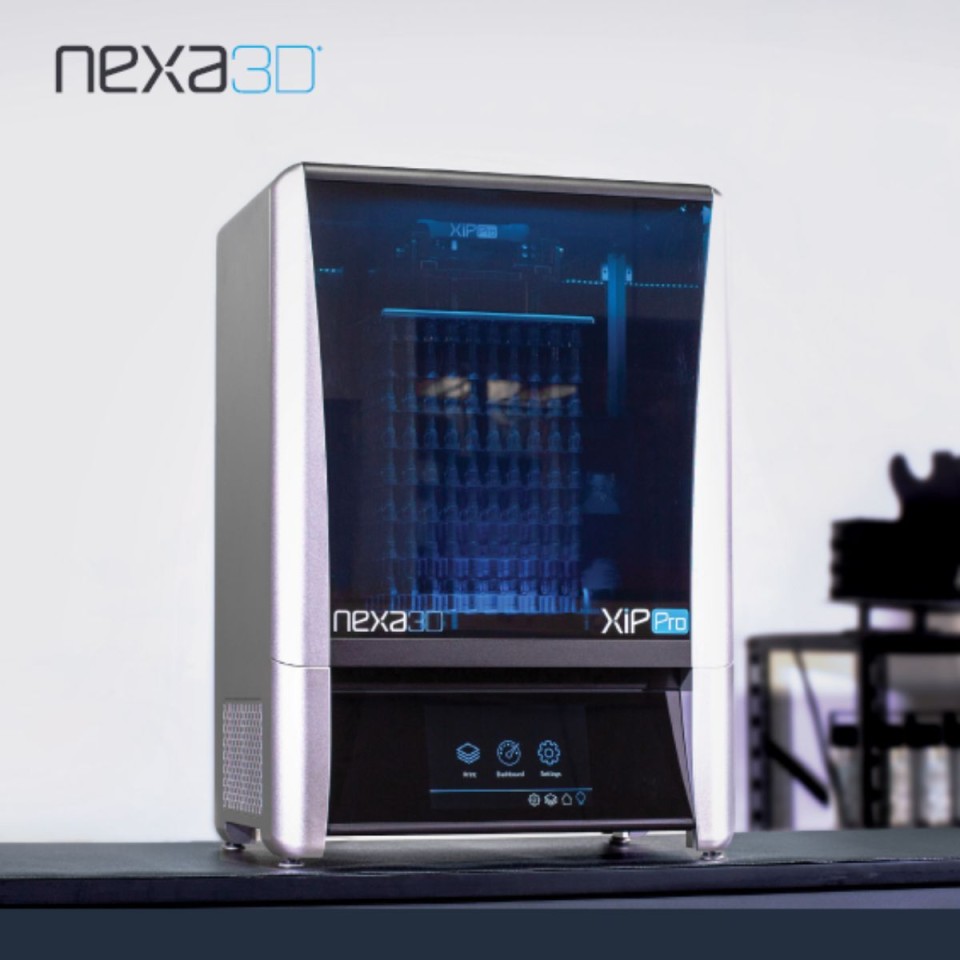

Take control of your supply chain and warehousing. The XiP Pro's ability to produce custom parts within hours allows for reduced operating costs and environmental footprint. Say goodbye to costly warehousing and disrupted supply chains.

The Nexa3D® XiP Pro is the next generation of industrial resin 3D printers and delivers the highest throughput with low operating costs, as well as the largest build volume and fastest print speed in its class. The unmatched productivity of the XiP Pro enables you to produce functional prototypes and end-use parts at unprecedented production conditions. The modern, LCD-based VAT photopolymerization process uses the patented Lubricant Sublayer Photocuring (LSPc) technology to deliver high levels of detail, excellent dimensional accuracy and excellent surface quality.

Technical specifications:

Build volume: 292 x 163 x 410 mm

Technology: LSPc® 7K

Vertical speed (when the build platform is full)*: 24 cm/h

XY resolution: 46 µm

Z resolution (layer thickness): 25 µm - 200 µm

The XiP Pro can fill its 19.5 L build volume at a speed of 24 cm/h in under two hours. Using LSPc® (Lubricated Sublayer Photocuring) technology, the XiP Pro is able to offer unrivaled speed with no loss of part quality or performance. By stacking smaller parts, the complete construction volume of the XiP Pro can be optimally used.

The Nexa3D® XiP Pro features a powerful light engine with a Monochromatic 7K LCD screen and a self-lubricating membrane that delivers unprecedented resolution, consistency, and detail, enabling the printing of beautiful, dimensionally accurate parts.

For fine details, smooth surfaces and improved precision, the XiP Pro has a pixel size of 46 μm and its Anti-aliasing technology delivers even better surface quality and a sub-pixel resolution of 23 μm.

The solid billet aluminum unibody frame delivers strength, durability and z-axis stability for maximum accuracy and reliability - all in a compact format that fits into any environment.

The Nexa3D® XiP Pro features an advanced set of sensors including environmental monitoring that helps deliver consistent results from print to print. In addition, it is equipped with an adaptive print speed control that optimizes the process parameters based on the geometry of the parts and the resin used. The closed-loop of the z-axis, including smart-homing, collision avoidance and debris detection, allows safe and precise printing and exact control of the layer height, even with viscous resins.

The Nexa3D XiP Pro is able to make the most out of a number of different types of resins. From durable and strong resins such as the xABS, xPP, and xCE, flexible resins such as xFLEX475 and xFLEX405, clear and modeling resins such as xMODEL15 and xMODEL17, high heat resins such as xPEEK and xCERAMIC, a range of validated dental resins and for almost everything else because of its open material platform.

NexaX Pro is the powerful and easy-to-use print preparation software that makes the XiP Pro what it is. You can import, analyze or repair one or more files, arrange your parts on the build tray or vertically and use custom material profiles to expand your portfolio of materials. Once done, you can send your print jobs to the printer remotely and monitor the print status from anywhere.

xWASH and xCURE ensure high-throughput post-processing and uncomplicated washing and curing of large print jobs from your XiP Pro. With an average total post-processing time of 40 minutes, all you have to do is start the process and your print job is done.

Analyze parts for the ideal printing process and use the material selector and build simulator to identify key geometries, material properties and areas for cost reduction.

Use LSPc® (Lubricant Sublayer Photo-curing) technology and print your part at lightning speed with the Nexa3D® XiP Pro.

To wash off the excess resin, the printed parts are cleaned using either the Nexa3D® xWash or another washing station.

In order for the specified material properties to be achieved, the printed parts must be post-exposed either with the Nexa3D® xCure or another post-curing device.

Produce complex objects quickly and cost-effectively, whether in small series or as one-offs.

With the Nexa3D® XiP Pro, manufacturing and assembly processes become simpler and more reliable, cycle times are reduced and employee safety is improved.

Review your design before going into production. Test geometry, fit and function with an accurate representation of the final product.

Create dental and orthodontic models, flexible bite splints, splints and bleaching trays, custom impression trays, drilling templates, surgical guides and other dental applications.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy