3D printers

High quality 3D printers

The filaments used in 3D printing are thermoplastics, which are plastics that melt when heated and solidify when cooled. The printer's extruder assembly moves as the filament is fed into a heating chamber, where it is heated to its melting temperature and then extruded through a metal nozzle, which follows a predefined path to build up the printed object layer by layer. Although many 3D printers have only one extruder, there are several dual-extruder versions that can print an object in different colors or with different types of filament.

Fused Filament Fabrication (FFF) or Fused Deposition Modeling (FDM) are two terms used to describe the plastic filament printing process. A special feature of Fused Deposition Modeling is that complex geometries can be produced from well-known thermoplastic materials such as ABS, PC, PEEK and PA. In addition, it is possible to fabricate support structures for overhangs using a support material. The support material can then be dissolved downstream.

The appropriate 3D printer software is used to prepare the data. The software generates any necessary supports and creates the G-code. The prepared data is then transferred to the 3D printer and processed.

Before printing can be started, the material supply must be checked. This step ensures that there is sufficient print material for the printing process.

In the third step, the actual printing of the component takes place. During this process, the extruder traverses the cross-section of the component and deposits the material through the die. The process is repeated for each individual layer.

Any necessary supports are then removed. Depending on the support material, the supports can be removed either by hand or in a water bath.

The components can be further processed afterwards as desired and if necessary. The components can be painted or mechanically processed, for example.

By manufacturing components from high-performance plastics such as ULTEM and PEEK, even the most demanding applications can be implemented. The Fused Deposition Modeling process allows you to process certified materials for aerospace applications.

In the automotive industry, the Fused Filament Fabrication process is used in particular for prototyping. Prototype vehicles and pre-series models can be realized in a very short time. FDM also offers the possibility of printing large components.

The FDM process is increasingly being used both in apparatus engineering and in the production of implants. In addition, auxiliary elements and spare parts can be printed from certified materials.

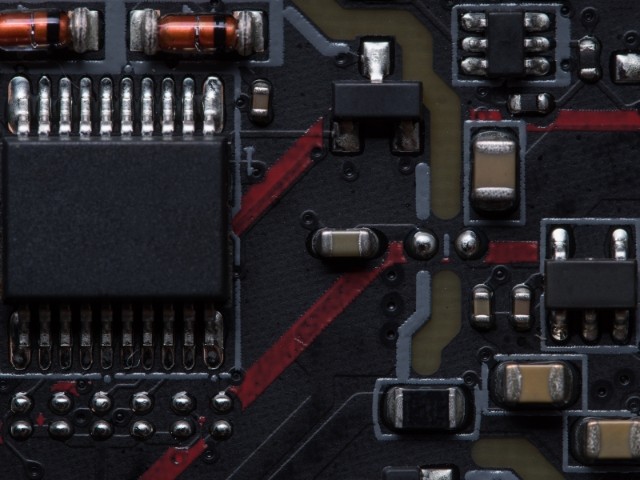

The use of ABS-ESD, a polymer of ABS with carbon nanotubes, provides excellent printing characteristics and outstanding ESD properties for use in critical applications requiring electrostatic discharge protection.

Typical consumer products made with 3D filament printing include eyeglass frames, shoes (sandals, insoles, midsoles) and sporting goods. They take advantage of 3D filament printing for customization and optimization of product features.

Cost-effective materials and short print times make filament 3D printing ideal for the iterative design process. 3D-printed prototypes can be used to visualize concepts or test the functionality of technical parts.

Our team of experts will be happy to support you in choosing the right 3D printing technology and in selecting the right 3D printing system.

Our application team also advises you on the choice of materials. Among other things, we can provide cost and time calculations as well as sample parts. In our showroom we have the possibility to validate the project together with you!