3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

The Sinterit NILS 480 is a new industrial-standard SLS 3D printer with a high level of automation and the best return of investment on the SLS technology market.

The Sinterit NILS 480, specially developed for industrial applications, is the new top model from Sinterit.

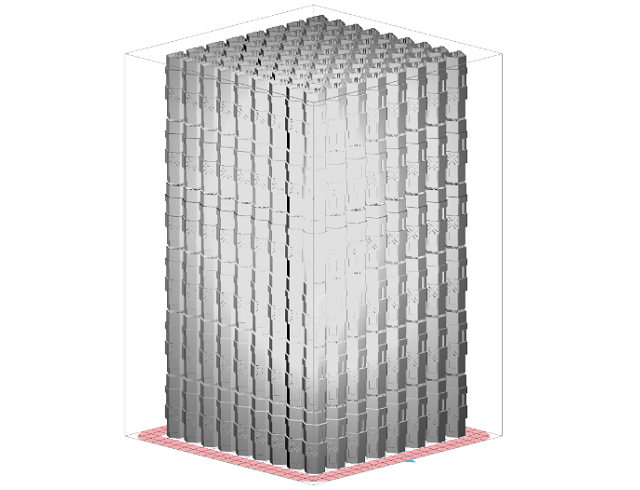

Use the freedom of SLS technology to generate complicated components without support structures. Create your designs without having to consider the geometric limitations of conventional manufacturing processes.

With Sinterit's extensive powder selection and the large build volume of the NILS 480, you can innovate and push the boundaries of additive manufacturing.

Print at unprecedented speeds thanks to the new galvo laser system.

The separation of the process and cooling chamber avoids long and unnecessary waiting times. The subsequent print job can now be started immediately.

Technical data:

Build volume: 200 x 200 x 330 mm

Maximum print diagonal: 435 mm

Building speed: 10-14 mm/h

Laser type: IR 30 W

The Sinterit Recoater is an innovative solution designed for millions of repetitions, making the Sinterit NILS 480 a process-safe industrial production system.

The Sinterit NILS 480 is equipped with a powerful 30 watt IR laser. The new galvo laser scanning system significantly reduces build times so that even large build jobs are completed within 24 hours.

Automated movement to the integrated cooling chamber enables continuous printer operation.

While the already finished components are cooling under defined conditions, actual production is already continuing in the process chamber.

Subsequent print jobs are already stored in the queue and are automatically fed for the printing process.

The Sinterit NILS 480 has the largest work area of any Sinterit SLS 3D printer.

It has a work area of 200 x 200 x 330 mm and, because of this size, can produce significantly more parts at a lower cost per piece.

Thanks to a closed powder management system and the new powder hopper design, filling the machine is "touch-free".

The user no longer comes into direct contact with the sintering powder.

Up to three printing processes can now be implemented with the existing material before refilling becomes necessary.

Once a print process is complete, the entire build job is automatically pushed into the integrated cooling chamber to cool down to the removal temperature under defined conditions.

Now the next printing process can start immediately without any time delay.

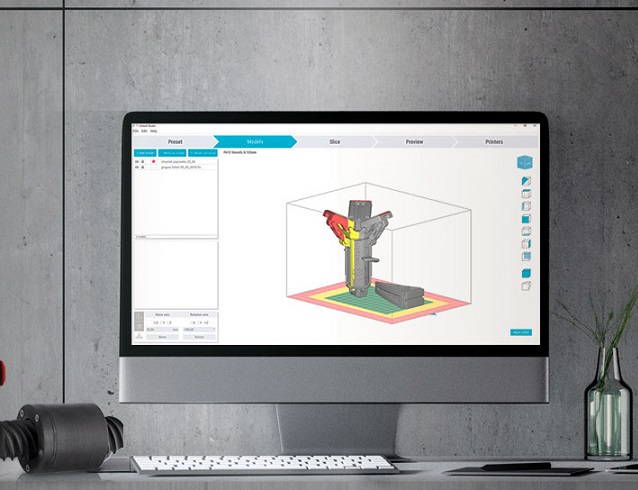

The clear, interactive 15.6-inch touchscreen lets you control the entire printing process.

Alternatively, the printer can of course be integrated into your existing network to manage all processes directly from your workstation.

For each Sinterit material, a pressure profile has been carefully developed to guarantee you the best possible component quality.

Nevertheless, Sinterit offers you the freedom to adapt these parameter sets individually for your application.

Produce stable parts for the end user or investigate the portfolio of their products in terms of feasibility using additive manufacturing.

Generate components that meet their stability or complexity requirements in countless applications.

Do away with unnecessarily expensive warehousing and produce the spare parts you need directly on-site.

Verify your design before going into production. Test form, fits, and function with an accurate model of your final product.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy