3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

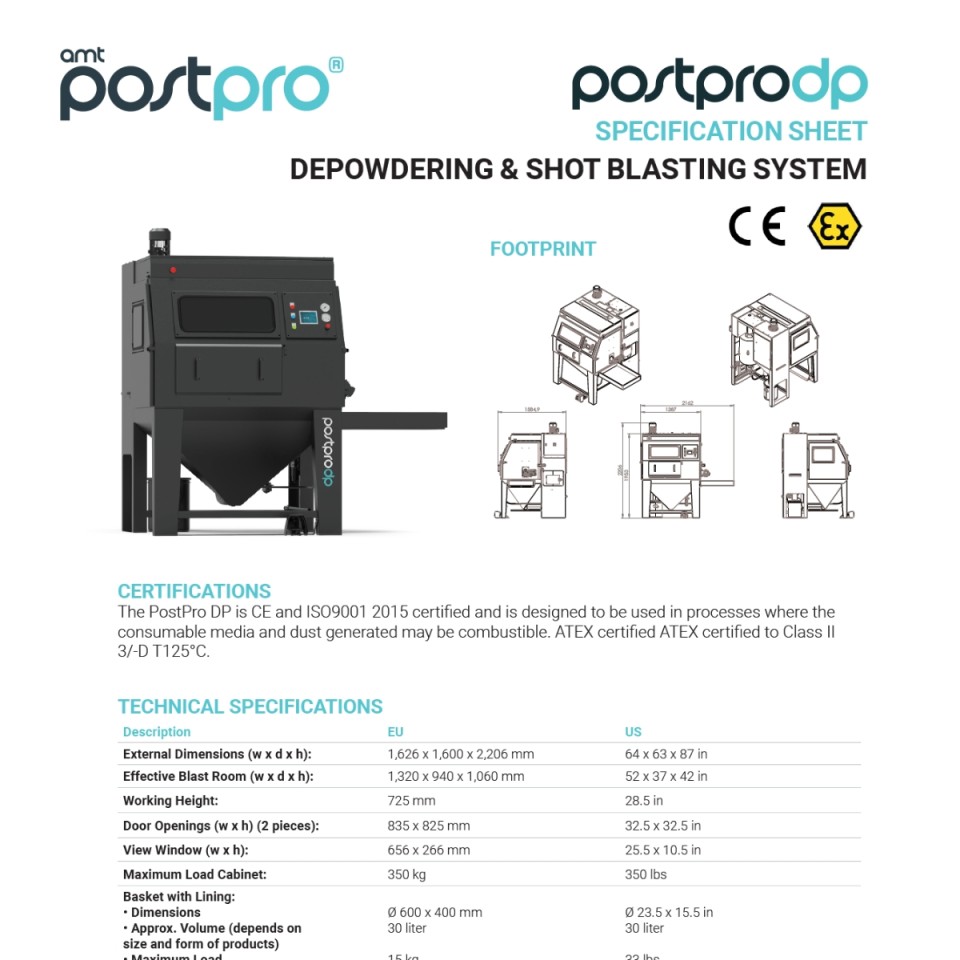

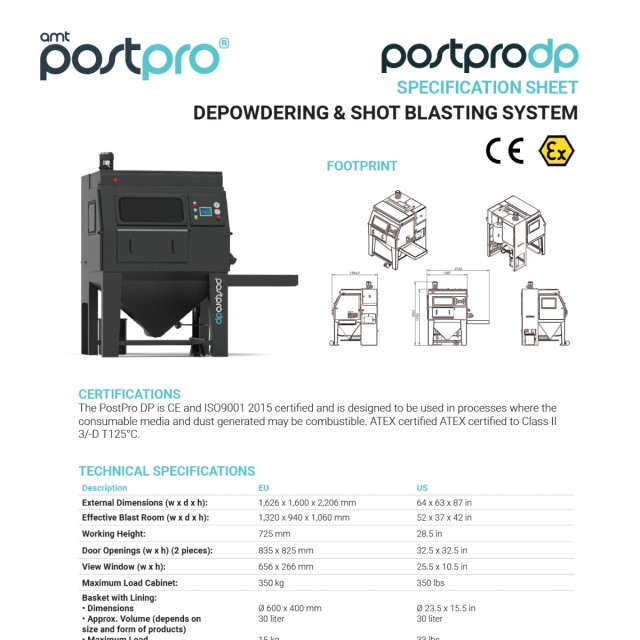

The PostPro DP is an innovative industrial automated depowdering system that optimizes the post-processing workflow for 3D printed items by efficiently removing excess powder using high-pressure compressed air and specialized media.

The PostPro DP is an advanced automated depowdering system that is specifically designed to streamline the post-processing workflow for 3D printed parts created using powder bed fusion technologies such as selective laser sintering (SLS), selective absorption fusion (SAF™), and multi-jet fusion (MJF). This method uses high-pressure compressed air in conjunction with specific abrasive media to successfully remove extra powder from printed components, leaving them immaculate and ready for immediate use or additional processing. By automating the depowdering process, the PostPro DP dramatically decreases manual labor needs while improving batch-to-batch consistency, which is critical for maintaining the integrity and quality of complicated geometries common in additive manufacturing.

The PostPro DP includes adjustable cleaning parameters, allowing operators to tailor the depowdering process to the material and shape of each item. It also has integrated ionized air technology, is ATEX certified, and is compatible with all standard engineering abrasive media, such as glass and ceramics, allowing users to choose the best media for their individual cleaning requirements. The PostPro DP stands out as a comprehensive solution that improves productivity and safety in post-processing workflows across numerous industries, thanks to its strong construction, user-friendly touchscreen interface for easy parameter adjustments, and effective dust separation filtering system.

Technical specifications:

Basket Size: Ø600 x 400 mm

Basket Volume: 30 liters

Basket Loading Weight: 15 kg

Blast Gun: Double with Ø8 mm nozzle

The PostPro DP uses a fully automated depowdering process that combines high-pressure compressed air with carefully selected abrasive media to effectively remove excess powder from 3D printed components. This automation considerably decreases the need for manual labor, hence optimizing manufacturing operations and increasing operational efficiency. The technology offers consistent and complete cleaning outcomes by following established cleaning recipes that are matched to each part's material and geometry. This is especially important for preserving the integrity and quality of complicated geometries, as any remaining powder can impair both the visual and functional aspects of the final product.

One of the PostPro DP's distinguishing advantages is its ability to tailor cleaning parameters based on specific part needs. This versatility enables operators to choose the best abrasive medium and change settings like pressure and time for maximum cleaning results. The system's adaptability is critical for tolerating a wide range of materials used in additive manufacturing, including polymers and composites. Users may achieve excellent surface finishes while keeping fine features thanks to precise control over the depowdering process, which is critical in industries such as dental, aerospace, and jewelry, where high precision is required.

The PostPro DP uses innovative ionization technology to efficiently eliminate static buildup during the depowdering process. Static charge can draw small powder particles back to cleansed surfaces, contaminating them and reducing part quality. The ionization unit generates ionized air, which neutralizes static charges and removes even the smallest particles from the components. This feature not only improves cleanliness, but it also removes the need for further cleaning procedures after depowdering, expediting the entire post-processing operation. As a result, the surface is immaculate and ready for further finishing procedures, which are crucial for producing high-quality end products.

Safety is a top priority in any manufacturing environment, especially when working with flammable powders. The PostPro DP is ATEX certified, which means it passes stringent safety requirements for use in areas where combustible dust may exist. This accreditation gives operators piece of mind when utilizing the equipment in potentially hazardous settings. Furthermore, the equipment meets CE and ISO9001:2015 standards, demonstrating its commitment to safety and quality assurance. The PostPro DP prioritizes safety through robust design and certification, allowing manufacturers to operate confidently while reducing the risks associated with dust collection.

The PostPro DP works with all typical technical abrasive media, such as glass beads, corundum, and ceramics. This adaptability enables customers to select the most effective media based on their specific cleaning requirements and component materials. Different abrasive media can produce varying levels of surface quality and cleaning efficacy; therefore, having this versatility allows manufacturers to adjust their procedures for optimal outcomes across a wide range of applications. The PostPro DP's flexibility to deal with different media types not only improves cleaning efficiency but also opens up a wider range of applications within additive manufacturing, making it a useful asset in any production environment that values quality and precision.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy