3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

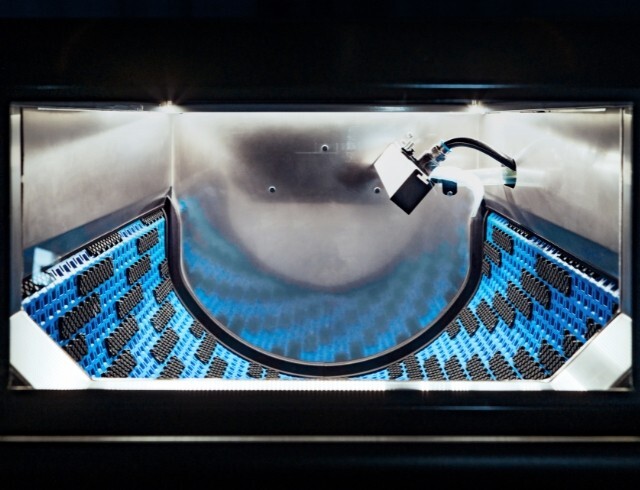

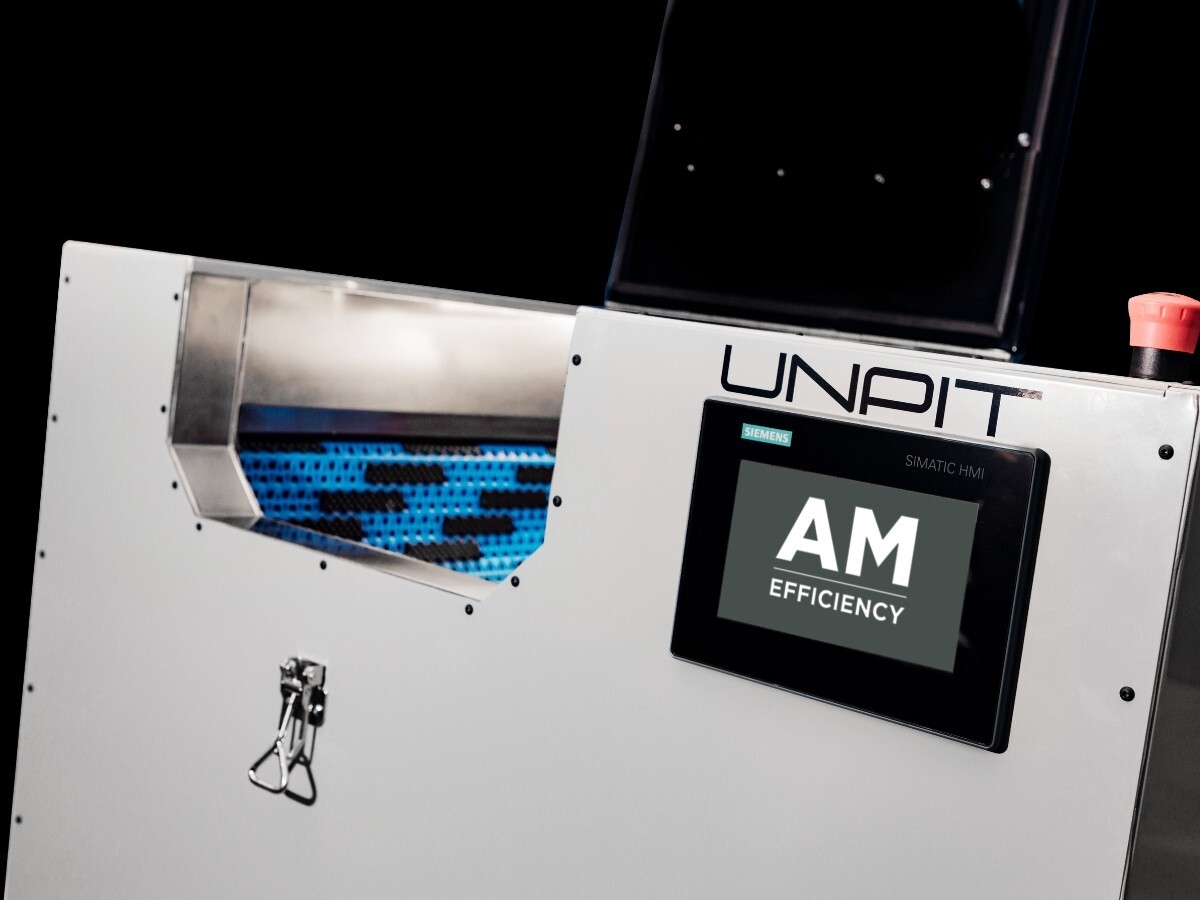

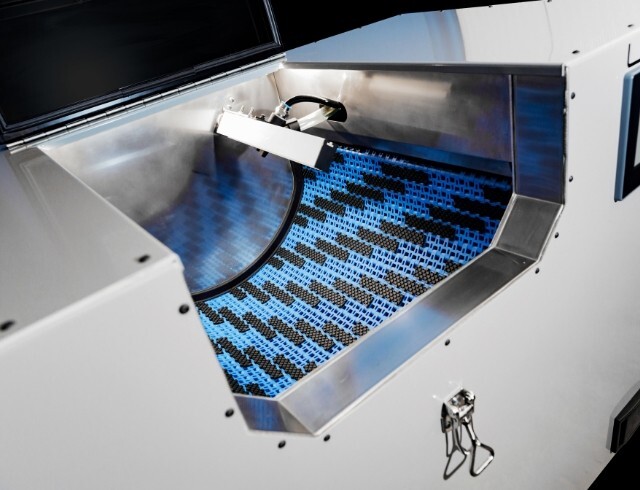

The “UNPIT - AM Part Processing” automates the complete post-processing workflow of 3D printed powder parts, including uncaking, depowdering, cleaning, and powder recovery, in one smooth process. It is designed to prioritize efficiency, creativity, and sustainability.

The UNPIT, manufactured in Sweden, exemplifies AM Efficiency's commitment to innovation, efficiency, and environmental responsibility in the 3D printing sector. The UNPIT streamlines the post-processing workflow, allowing users to maximize productivity and consistently produce high-quality final components without manual intervention.

UNPIT is a revolutionary automated post-processing solution created exclusively for entry-level Selective Laser Sintering (SLS) 3D printers. This novel 4-in-1 system combines unpacking, depowdering, cleaning, and material recovery into a single, compact machine, transforming the additive manufacturing workflow. It is designed to perform the full post-processing cycle automatically, which considerably reduces labor and time requirements.

The UNPIT's automation not only improves efficiency, but it also addresses ergonomic problems by removing physical handling of parts and powder particles. Its high material recovery rate enables virtually 100% recycling of wasted powder, promoting sustainability and cost savings in the additive manufacturing process.

Technical Specifications:

Max Cake Height: 400 x 250 mm

Air Pressure: Minimum 4 Bar, Maximum 8 Bar

Air Consumption: Approx. 250 liters per minute

Sound Level: Approx 70 dB

The UNPIT transforms the post-processing phase of additive manufacturing by seamlessly combining four crucial phases into a single automated machine. This four-in-one solution starts with unpacking, in which the 3D printed powder parts are separated from most of the “cake”. It then proceeds to depowdering, which involves carefully removing extra powder from the parts' surfaces and intricate cavities to ensure a clean finish. The cleaning stage follows, fully preparing the pieces for immediate usage or subsequent processing. Finally, the material recovery process takes wasted powder and prepares it for reuse in subsequent print runs. This extensive automation considerably speeds the operation, saving time and labor typically required for post-processing 3D printed powder parts.

The UNPIT's user-friendly design simplifies an otherwise complex and labor-intensive operation. Operators merely need to transfer the "cake" - the produced pieces still wrapped in powder - directly from the 3D printer to the UNPIT. The machine takes over after just selecting the suitable program adapted to the exact pieces or materials. This simple interface eliminates the need for substantial training or specialized expertise, making complex 3D printing post-processing available to a wider variety of consumers. The UNPIT's capacity to manage the full post-processing sequence automatically simplifies processes while also ensuring consistency between batches, lowering the risk of human error.

The UNPIT system significantly improves workplace safety. Traditional post-processing processes can involve repetitive actions and continuous exposure to small powder particles, which might pose health problems over time. The UNPIT avoids ergonomic dangers by automating the physical processes of post-processing. This reduction in manual handling not only protects workers from potential musculoskeletal problems, but it also reduces their exposure to potentially hazardous powder particles assisting businesses in complying with occupational health and safety standards.

The UNPIT's material recovery capabilities mark a big step forward in additive manufacturing resource efficiency. With its high recovery rate, which supports nearly 100% material recycling with almost no waste, the system effectively collects excess powder that would otherwise be discarded, preparing it for prompt reuse in following print runs. This closed-loop approach to material handling not only avoids waste but also saves money, particularly when dealing with expensive or specialized powders. The capacity to effectively recycle materials contributes to the overall sustainability of the 3D printing process, in line with rising environmental concerns and regulatory requirements. Furthermore, the constancy of the recovered material contributes to maintaining print quality across several jobs, guaranteeing that recycled powder fulfills the same criteria as virgin material.

The UNPIT is designed with compatibility in mind, and it offers amazing adaptability, especially for users of entry-level Selective Laser Sintering (SLS) 3D printers. This broad compatibility assures that its advanced post-processing capabilities can be used by a wide spectrum of additive manufacturing operations without requiring significant equipment adjustments. The UNPIT's ability to adapt to different materials and part geometries makes it useful for a wide range of applications, from prototype to small-scale production. Its adaptability extends to diverse batch sizes and part complexities, resulting in a scalable system that can expand with a company's 3D printing requirements.

Fill out the form below, and we will email you the datasheet.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy