3D printers

High quality 3D printers

Additive Manufacturing is increasingly finding its place in this progress. Whether it's advancements in patient safety and well-being, advancements in surgery preparation and simplification for surgeons, or advancements in precision-fit implants and organs - 3D printing is at the forefront.

Additive Manufacturing is not just limited to one area of medicine. Dentistry, neurosurgery, veterinary medicine, and even forensics are now using 3D printing and its advantages.

I would like to dedicate this blog post to the greatest benefits of 3D printing within medicine. Since I am not a medical professional, my descriptions of medical procedures will be laymen at best. Nonetheless, I hope to accurately report on the possibilities of additive manufacturing within medicine.

But now, after this long preface, to the advantages!

Implants, no matter what kind, are expensive. Even uniform implants can cost thousands of euros to manufacture. If individual implants are required, the costs increase rapidly.

In addition to the costs, there are sometimes long waiting times. While standard implants can still be obtained quickly, waiting times of several weeks to several months are planned for individual implants.

For many patients, these waiting times are associated with great pain. In emergency situations, uniform implants are then often used to skip the waiting time - but in the worst case, this can lead to complications and thus further pain for the patient.

Additive Manufacturing provides a remedy for these problems. It enables implants to be manufactured much more quickly and cost-effectively. This manufacturing can also be moved directly to hospitals to avoid long delivery times. As a result, emergency operations with precisely fitting implants can be performed far more quickly, which can save patients' lives.

Titanium is most commonly used for implants. This metal offers excellent strength, durability and biocompatibility. Apart from this however, thanks to the wide range of materials, there are many other materials from which implants can be made. PEEK and silicone can now for example also be used to manufacture implants.

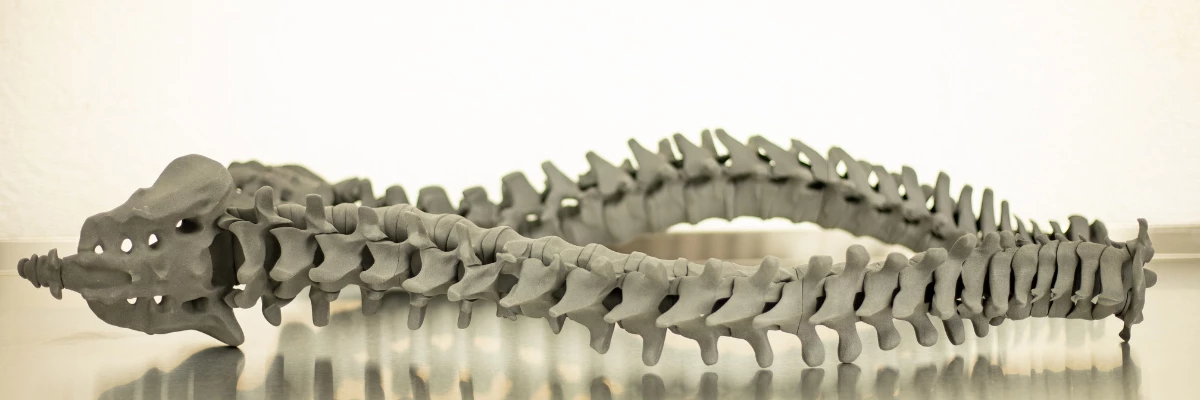

3D printing is suitable for a wide range of different implants. Teeth, knee joints, cruciate ligaments, and parts of the pelvic bone and sternum are now among the standard applications for Additive Manufacturing in the field of implants.

In addition, jaw and even skull implants are now possible with the help of Additive Manufacturing. Just a few months ago for example, a PEEK skull implant was successfully transplanted into a patient at Salzburg University Hospital.

3D printed implants are also creating new opportunities for the animal world. From prosthetic legs for dogs to a new beak for parrots, Additive Manufacturing is opening up new possibilities in veterinary medicine as well.

Implants are becoming increasingly important. The average age is rising, people are getting older and so are their bones, teeth and joints. In the last 20 years, the number of dental implants needed alone has risen from about 380,000 to about 1.3 million in Germany. In 2021, there were a total of 172,011 knee implants in German hospitals, and even the number of under-60s with knee implants is steadily increasing.

The fast and cost-effective production of implants of all kinds will therefore become increasingly important in the future. At the same time, Additive Manufacturing will continue to develop to provide medicine with more materials, more purposes and more possibilities.

One development I would like to focus on in particular is research into materials with antimicrobial, ergo infection-fighting, properties for Additive Manufacturing. Researchers at the UK's University of Bath, in collaboration with Ulster University, issued a press release in early April presenting their latest findings on this research.

Briefly summarized: The material manages to kill 70% of the bacteria in just 15 minutes, even at high concentrations of aggressive E. coli bacteria.

Such an antimicrobial material can dramatically reduce the risk of infection, both reducing treatment time and costs by reducing the need for costly follow-up surgery due to infection and increasing patient comfort.

In addition to reducing costs and time, Additive Manufacturing also increases patient safety. However, not only in terms of antimicrobial material. An important aspect of patient safety is the preparation of surgeons for an operation - and here, too, Additive Manufacturing can provide assistance.

The third leading cause of death in the United States is medical errors. As advanced as technology may become, until surgeries are completely taken over by robots, there will always be human errors in medicine that cost patients their lives.

In surgery, it doesn't take major lapses; all it takes is a small moment of carelessness or an unforeseen bleed to cause a life-threatening complication.

Of course, 3D printing can't magically set the error rate to zero. It can never ensure that all doctors are prepared for every possible difficulty at all times. But Additive Manufacturing can make surgeon preparation and even training easier and more realistic.

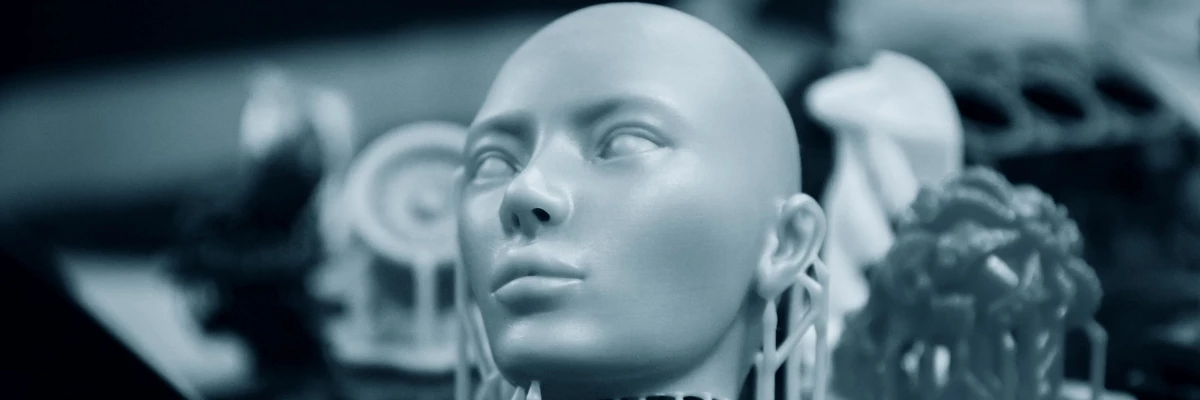

3D printing allows surgical models to be produced with high speed and precision. The increased speed helps giving surgeons more time to prepare, while the increased precision makes preparation more realistic, reducing errors and allowing surgeons to anticipate the unexpected sooner.

In many cases, these surgical models can even be adapted directly to the patient's own characteristics. The size, shape, weight and many other factors of these models, whether organs, joints or bones, can be reproduced as a digital model based on CT scans and then printed out on a 3D printer.

However, realistic models not only help surgeons who are already practicing - surgeons in their studies also benefit from them. Until now, students have mainly used organs, joints, bones, etc. from deceased patients, but these were very expensive and difficult to obtain. 3D printing enables the rapid, accurate and cost-effective replication of all these practice models to continue to provide students with a realistic study experience, but without the horrendous costs previously associated with them.

Last but not least, these models also help patients and relatives before the operation. Using these models, surgeons can show their patients in detail how the operation will proceed, what problems might arise and how these problems can be overcome. For some patients and family members, this pre-operation demonstration can give them peace of mind - even if others, like me for example, would faint just from being shown.

Additive Manufacturing is becoming more detailed, more precise and faster. New technologies are being developed, new printers are coming onto the market, new materials are being produced - permanently.

For surgeons, whether practicing or aspiring, this means a higher level of detail with minute subtleties for practice and preparation. And the closer to reality the practice model is, the more likely errors can be prevented.

Today, many clinics and hospitals are already using 3D printing to prepare for surgery. From Leipzig University Hospital to the Hôpital Marie-Lannelongue near Paris to Seattle Children's Hospital, 3D printing is already helping many surgeons around the world.

Over time, this technology will become more widespread, allowing even more surgeons to prepare their operations on realistic models, saving patient lives worldwide.

Maybe, actually hopefully, Additive Manufacturing will even manage to drastically change the statistics of causes of death by massively reducing medical errors. I can't predict it, but there's no doubt it's possible.

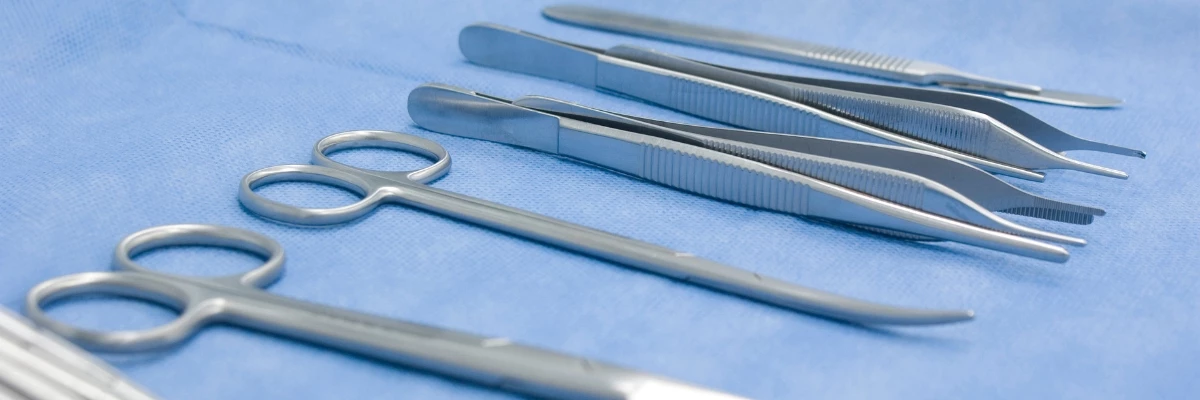

Medical instruments are essential in every hospital. Scalpels, drill templates, retractors, curettes and all the other wondrous devices that make surgical procedures possible.

These instruments are mostly produced in very small numbers. This is mainly due to the different dimensions in which all these instruments are required. Due to this low production number, the instruments are often relatively expensive - a single retractor, for example, can cost over 15 euros - and due to the many different dimensions, a total of many individual instruments are still required, which multiplies the costs.

In addition to cost, availability can also become an issue. During the Corona pandemic, there were some shortages of medical instruments because most of their production was outsourced to Asia, and developing countries have shortages of medical instruments even in the absence of a global pandemic.

Additive Manufacturing can't make either problem disappear into thin air - but it can help mitigate them!

Before we get to cost and availability, I'd like to highlight another huge advantage of Additive Manufacturing for medical instruments - increased customization.

Additive Manufacturing enables new geometries that would be impossible with conventional manufacturing. This allows certain instruments to be refined, other instruments to be joined, and almost all instruments to be customized to the physician and the patient. This allows more options for physicians and surgeons to perfectly adapt their instruments to the circumstances without incurring massive additional costs.

The cost of medical instruments, whether custom or universal, can be massively reduced through Additive Manufacturing. In a 3D printer, several different components can be produced in a single printing process, ergo also different dimensions from the same instrument. This reduces not only the costs but also the manufacturing time enormously.

Reducing manufacturing time is also important to increase availability. Thus, in the event of possible bottlenecks, the required instruments can simply be manufactured in-house, which also saves storage capacity.

This self-manufacturing can also help hospitals in developing countries. Instead of long waiting times for delivery and very high cumulative costs, a one-time investment in a 3D printing system is all it takes to produce instruments quickly, easily and cheaply yourself.

Even though the Corona pandemic seems to be in the past by now, we should not forget our lessons from it. One of the most important lessons is undoubtedly that production needs the fastest possible response capability in emergency situations!

Masks, test sticks, protective equipment and much more were in short supply from one day to the next. Since most of the production of this medical equipment no longer takes place in Europe, the worldwide travel restrictions, especially at the beginning of the pandemic, were devastating.

Additive Manufacturing can be very effective in curbing the recurrence of such situations in the future. Even in the Corona days, test rods and masks were manufactured using Additive Manufacturing to compensate for supply shortfalls.

In those 3 years, yes it has actually been that long since the Corona pandemic began, 3D printing has proliferated, in part because of the pandemic. Far more medical facilities are now using a 3D printer to support their manufacturing of medical instruments.

This widespread use means that Additive Manufacturing can provide far more help in emergency situations to circumvent supply bottlenecks. Of course, it would simply be better not to have emergency situations with supply bottlenecks - but everything is going haywire at the moment anyway, so better to be unnecessarily prepared once too often than to end up regretting a lack of preparation. Especially in medicine.

The ever-increasing complexity of components that can be produced by 3D printing will also play a major role in the future of medical instruments. As a result, more and more different types of instruments can be produced through Additive Manufacturing. The development of completely new instruments through Additive Manufacturing and their great design freedom will also certainly play a role in the future.

However, what many researchers and medical professionals are focusing their attention on much more as far as the future is concerned, is the production of fully functional organs through 3D printing. What continues to sound like a distant future to some ears has been extensively researched and developed for a long time, and the results are truly amazing.

According to a press release from the German Foundation for Organ Transplantation (DSO), the number of organ donors declined in 2022. While there were 933 in 2021, there are 64 fewer in 2022. At the same time, about 8,500 people are waiting for a donor organ that can at least improve, and in many cases save their live.

Organ donation rates are far too low to help everyone in need. Last year, 2,695 people were helped by the transplantation of one or more organs. In correlation to the numbers on the waiting list, obviously too few.

There are various reasons for people to decide against organ donation. And even if they choose to do so, there are many requirements that must be met for organ donation - the most important of which is that the patient must die in the intensive care unit, as he or she must continue to be ventilated in order to continue to supply the organs with oxygen.

Organ donations are also essential for medical research. Such organs can be used to conduct tests for drugs that accelerate the approval process for effective cures.

Donors are missing, organs are missing. Unfortunately, Additive Manufacturing can do nothing about the missing donors - but it can do something about the missing organs, at least in the future.

3D printing organs sounds surreal to many ears - probably rightly so. Having a fully functional organ produced by machine seems like the creative brainchild of a science fiction author. But research into making 3D printing of organs a reality is progressing in leaps and bounds.

Boston University for example has already developed a miniature replica of a human heart that can be manufactured using Additive Manufacturing. Known as miniPUMP, this miniature heart, which consists of human heart and stem cells and microscopic 3D-printed acrylic parts, can beat independently thanks to its living tissue - just like a real human heart.

In Brazil, miniature replicas of a liver were produced completely additively. According to the researchers, these miniature organs, which are made of human blood cells, are capable of performing all the functions required by humans.

Active research is also being conducted in relation to the Additive Manufacturing of kidneys. For example, the U.S. company United Therapeutics and the Israel-based biotechnology company CollPlant are working together to enable perfect reconstructions of kidney tissue through 3D printing. In the first step, such kidney tissue could spare people with kidney failure dialysis; in the second step, it could enable complete replicas of kidneys.

Research into Additive Manufacturing of organs is still at the beginning of a long journey. It will be some time before we can transplant the first fully functional organ.

Nevertheless, the projects already in place, of which there are many more than I have listed, give hope. Hope to multiply the available organs to fundamentally change both medical research and organ donation statistics.

When exactly this will happen, however, is still written in the stars. Estimates of when this goal can be achieved vary widely. From a few years to several decades. But no matter how long it takes - hope remains.