3D printers

High quality 3D printers

Digital dentistry is driven by Dental 3D Printing. It is known for its reliability and high quality. A lot has changed since the first desktop 3D printers were made available for dentistry. A few years ago, only the largest dental labs could afford 3D printers, but today they are a staple in labs and practices of all sizes. The light or laser used in dental 3D printers polymerizes a liquid with the computer-controlled precision needed to make small things with fine detail.

Stereolithography (SLA), Digital Light Processing (DLP), Lubricant Sublayer Photo-curing (LSPc®) and Material Jetting (PolyJet and MultiJet Modeling) are the most popular 3D printing technologies commonly used in the dental industry today. Each technology can deliver the accuracy and precision required for dental applications, but the quality of different machines and systems can vary.

A laser beam is used to selectively expose liquid resin throughout the print area, thereby curing it. SLA printers offer large build volumes and a variety of materials for a wide range of applications. The resin tank and cartridge can be easily interchanged to use different materials. Desktop SLA printers are a good choice for dental labs and practices to get started with 3D printing in dentistry due to their small footprint, straightforward process and affordable price.

Digital Light Processing (DLP) uses the same chemical process as SLA printers, but instead of a laser to solidify the resin, a digital projector is used as the light source. DLP printers are much more expensive than desktop SLA printers, although they offer a smaller footprint, a simple workflow, and a wide range of material options. DLP products typically have poorer surface quality and are more likely to have voxel lines, layers made up of tiny rectangular building blocks caused by digital screens.

LSPc® technology starts with a uniform light source. Using a UV light array and a high-contrast mask responsible for projecting the 3D slices onto the tray where the photopolymerization process takes place layer by layer, a uniform, distortion-free image is created in all areas of the build plate, ensuring part-to-part uniformity and accuracy.

Material Jetting (PolyJet and MultiJet Modeling) Inkjet printers are similar to these 3D printers in that they spray layers of liquid resin onto a build plate and immediately cure these layers. In 3D printing, this is done by light. A few years ago, material beam technologies dominated dentistry, but their growth was limited by the high price and bulky size of the devices. The surface finish of objects produced with this technology is generally poorer than with SLA, DLP or LSPc® and therefore requires extensive post-processing.

For the production of high-precision dental prosthesis models. Print precise models or dies. Check fits and get accurate crown margins. Deliver high-quality results in the shortest possible time.

All products in the range are designed for dental splints. KeysplintHard provides therapy for bruxism and cases where immobilization of teeth is required. (Rigid). KeysplintSoft is for the treatment of bruxism with rather slightly flexible indications. (slightly flexible)

For high quality surgical drill guides that are autoclavable and biocompatible. Ideal for surgical drill guide for placing implants.

Print custom impression trays for implants, dentures, crowns and bridges, and other comprehensive cases. Digitally manufactured custom impression trays provide consistent, accurate impressions for high quality dental work.

For reliable casting without ash content in the fabrication of crowns, bridges and RPDs. The material burns out completely and has been tested by dental technicians for many years.

We are expanding access to digital dentures with an efficient, cost-effective manufacturing solution. The long-term biocompatible resins enable dental technicians to produce 3D-printed complete dentures precisely and reliably.

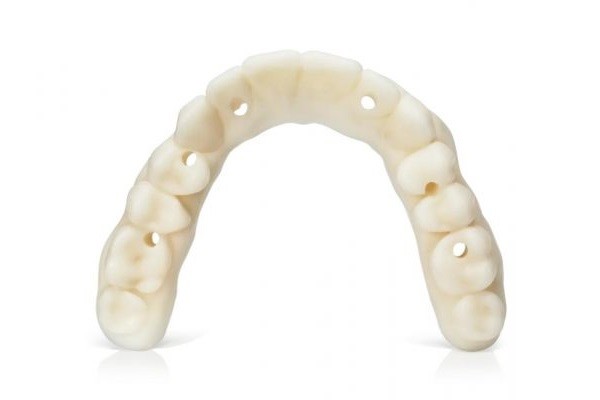

Ideal for up to seven-unit bridges and available in 4 VITA shades. 3D printing provides excellent marginal adaptation, strength and esthetics. The material can be cemented with conventional temporary cement. Dentures fabricated with Temporary CB Resin can remain in the mouth for up to 12 months.

For 3D printing of permanent single crowns, inlays, onlays and veneers. The low water absorption and smooth surface ensure that restorations made of Permanent Crown Resin hardly age or discolor and hardly accumulate plaque.

3D-printed transfer trays for the indirect bonding technique reduce chair time and increase patient comfort by allowing simultaneous placement of all brackets.

Flexible yet firm gingival mask that simulates the look and feel of gum tissue. Integrate Gingiva Masks into your digital restoration planning.

Our dental team will be happy to assist you in selecting the right 3D printing system. In addition, we will be happy to provide further information on the individual indications.

Our application team will also advise you on the choice of material. Among other things, we can provide cost and time calculations as well as sample parts. In our showroom we have the possibility to validate the project together with you.