3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

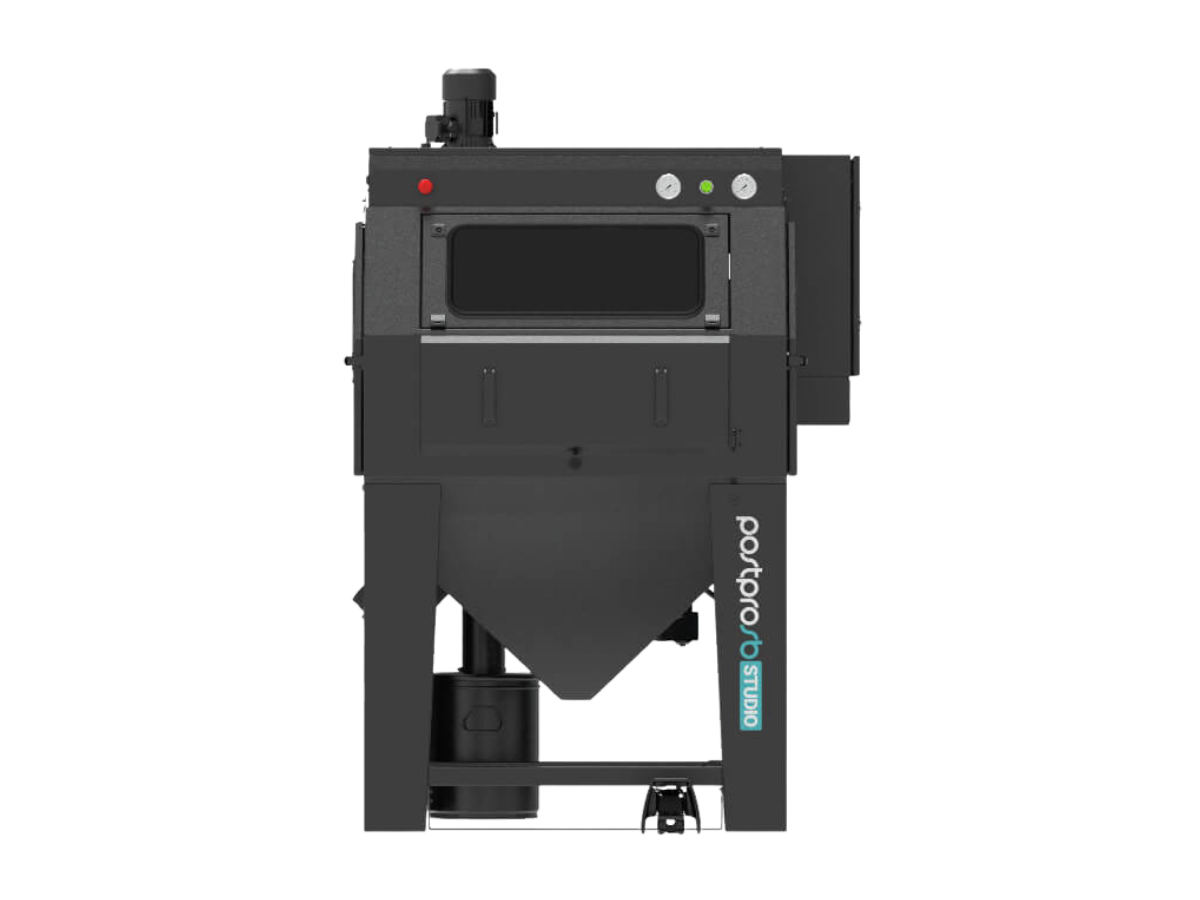

The PostPro SB Studio is an advanced automated surface blasting system designed to enhance the finishing quality of 3D printed parts by efficiently removing excess powder and improving surface smoothness.

The PostPro SB Studio is an innovative automated surface blasting device that is specifically developed to improve the finishing quality of 3D printed products. This unique equipment uses mechanical methods, such as shot blasting, to efficiently remove surplus powder and increase surface smoothness without using chemicals. The PostPro SB Studio automates the surface finishing process, which saves manual labor and the variability associated with traditional hand-finishing processes. This functionality is especially useful in high-volume production scenarios where consistency and quality are crucial, allowing producers to obtain a polished surface that matches demanding industry specifications.

The PostPro SB Studio's ability to handle a wide range of part shapes and sizes makes it appropriate for a variety of applications across industries. The system's architecture enables for quick modifications to fit various components, ensuring that each element receives the best treatment during the finishing process. Furthermore, the user-friendly interface allows operators to simply configure parameters and monitor the cleaning cycle in real time.

The PostPro SB Studio also prioritizes safety and environmental stewardship by removing the need for toxic solvents during the finishing process. This feature not only eliminates hazardous waste, but also facilitates compliance with health and safety requirements, making it a more sustainable solution for businesses.

Technical specifications:

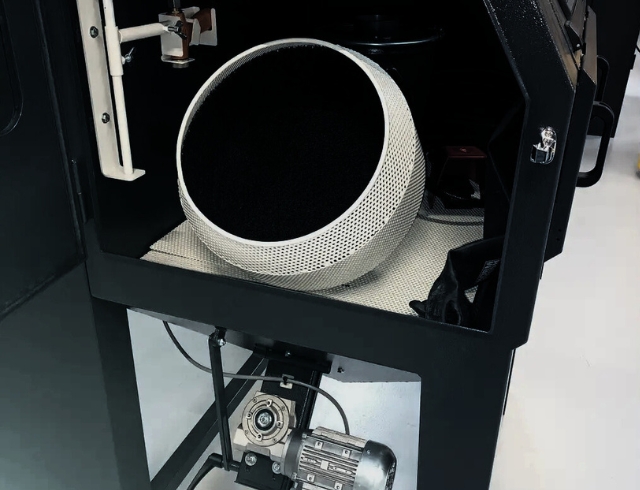

Basket Size: Ø450 x 210 mm

Basket Volume: 10 liters

Basket Loading Weight: 10 kg

Blast Gun: Single with Ø8 mm nozzle

Air Consumption: 1000l/min at 6 bar

The PostPro SB Studio employs innovative automated surface finishing technology, which is critical for improving the quality of 3D printed parts. By using mechanical methods such as shot blasting, the system successfully eliminates superfluous powder from the surface of parts, considerably improving their aesthetic and functional qualities. This automation reduces the need for manual work, which can be time-consuming and unreliable, lowering labor costs and the risk of human error. Furthermore, the automated procedure ensures that each part receives the same treatment, resulting in consistent surface finishes across batches. This is especially significant in areas that require precision and quality, such as aerospace, automotive, and medical applications.

One of the most notable features of the PostPro SB Studio is its ability to process a variety of part geometries and sizes. The system is designed to accept both tiny and medium-sized components, making it appropriate for a wide range of applications across industries. This versatility allows producers to easily process a wide range of items without requiring considerable reconfiguration or downtime between operations. The flexibility to handle many types of parts enables producers to respond swiftly to changing production demands or customer specifications. This feature not only improves operational efficiency, but it also fosters creativity by allowing the manufacture of complex geometries that necessitate specific finishing methods.

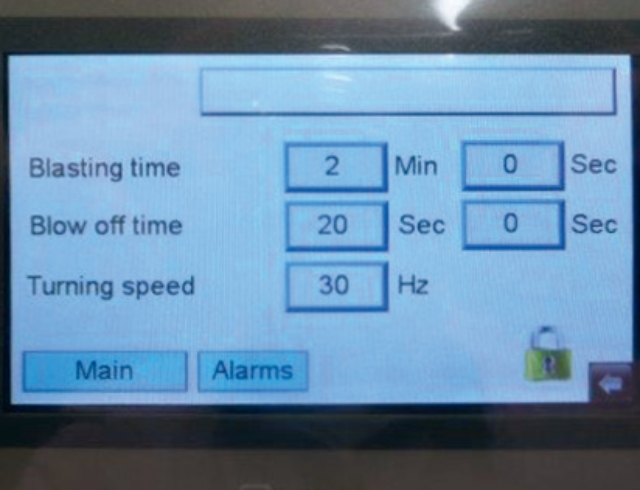

The PostPro SB Studio features an intuitive user interface that dramatically improves the entire user experience. The touchscreen control panel enables operators to simply browse through many settings and parameters, making it simple to configure and monitor the finishing process. The interface gives real-time input on operational status, allowing users to make fast adjustments as needed. This ease of use shortens new operators' training time, allowing them to become adept rapidly while reducing the possibility of errors during operation. The user-friendly interface boosts productivity by streamlining setup and monitoring operations, allowing manufacturers to manage their post-processing workflows more efficiently.

The PostPro SB Studio is notable for its devotion to ecologically friendly operations. Unlike traditional surface finishing systems, which frequently rely on chemical solvents or abrasive materials that are hazardous to both health and the environment, the PostPro SB Studio only uses mechanical processes. This removes the need for hazardous chemicals, resulting in significant waste reduction and simplified compliance with health and safety requirements. Manufacturers can improve their corporate social responsibility activities while still producing high-quality products by adopting a more sustainable approach to surface finishing. This emphasis on environmental sustainability benefits manufacturers while also aligning with rising customer demand for eco-friendly industrial practices.

The PostPro SB Studio includes a powerful dust management system that successfully captures and contains particulate matter created during operation. This technology is critical to maintaining a clean working environment because it prevents dust accumulation within the chamber, which can impede visibility and pose health risks to operators. The efficient dust control function comprises high-performance filtration devices that reduce airborne particles during operation. By maintaining appropriate air quality and cleanliness in the workstation, this feature not only improves operator safety but also adds to increased productivity by allowing users to focus on their duties without being distracted by dust.

The PostPro SB Studio is designed with quick-clean maintenance capabilities to allow for efficient waste disposal from the system. The sealed dust bin enables workers to effortlessly remove gathered dust and powder without causing a mess or exposing themselves to potentially hazardous chemicals. This practical design ensures a safer work environment by keeping contaminants contained during maintenance chores. Quick-clean capabilities also ease standard maintenance processes, decreasing downtime related with cleaning and upkeep. By optimizing waste management operations in this manner, the PostPro SB Studio promotes compliance with health and safety laws while improving overall operational efficiency in production environments.

Fill up the form below and we will send you the data sheet by e-mail.

(This post processing machine has the same data sheet and specifications as the PostPro DP Studio)

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy