3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

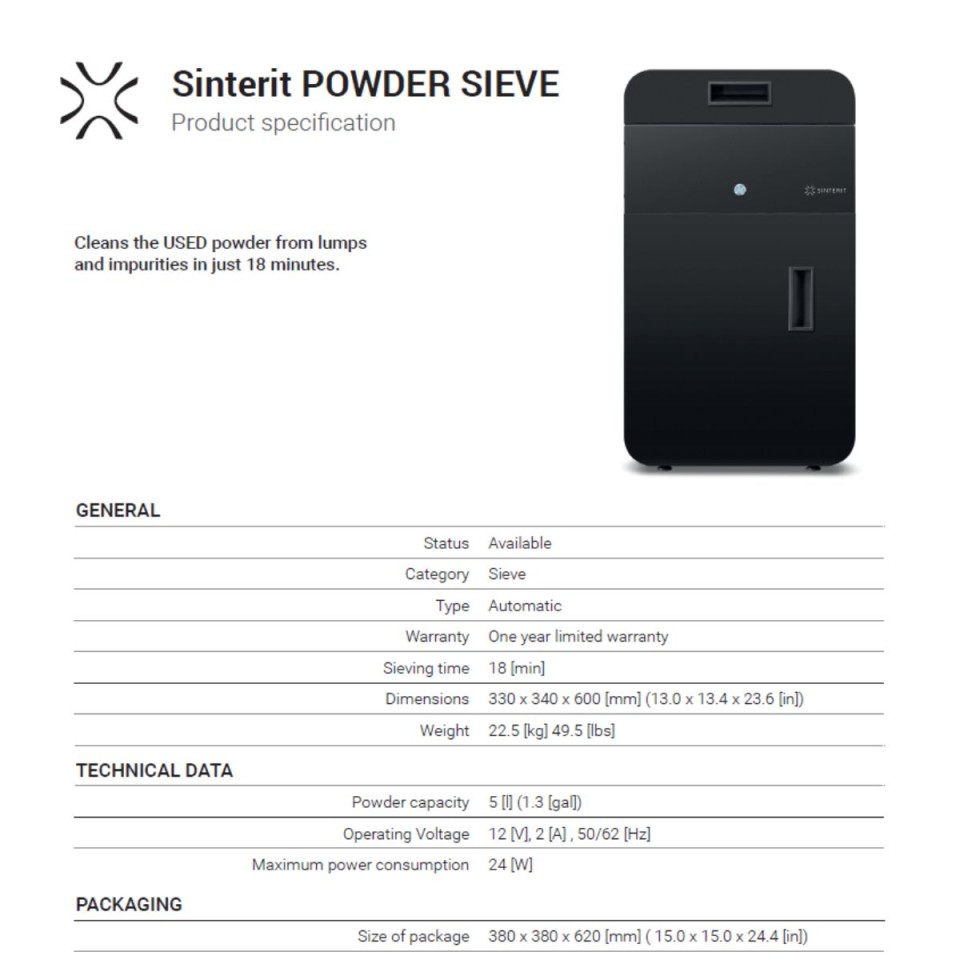

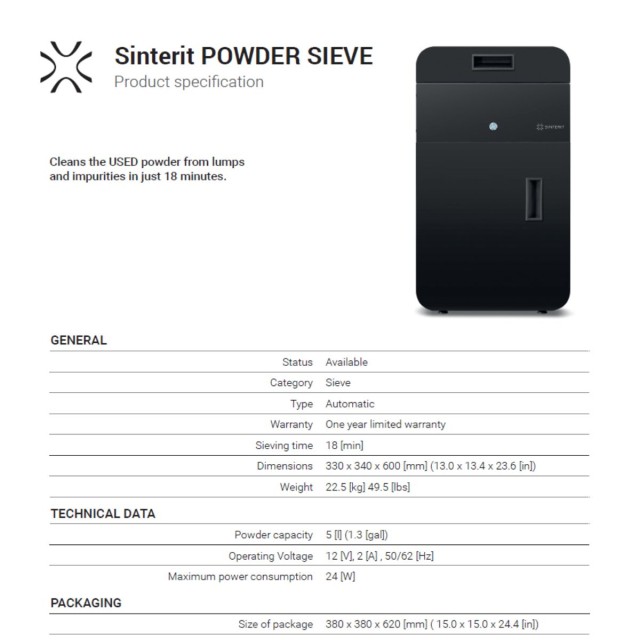

The automatic powder sieve is used for mixing since lumps of several centimeters to a few millimeters in size can occur during the printing process, sieving is essential for uniform powder quality.

For the production of new "reprocessed" powder (such as Sinterit PA12 Starter), the unit can be used to sieve previously used but unsintered powder. This allows the reuse of the material.

After printing, the powder is recovered and mechanically sieved to remove lumps and other impurities. This helps to ensure that the resources used in the production process are optimally utilized.

The equipment consists of a vibrating screen, which is driven by a vibration motor. If necessary, the screen can be removed for cleaning and used to filter various plastics. The one-button operation is very simple and is used to start/stop the sieving process. The process ends automatically after about. 18 minutes.

Just press the button after putting the used powder into the machine. The use of the powder sieve is simple; after pressing the button, the machine performs the task.

Reuse the material after cleaning to print new models by mixing it with fresh powder. Remove lumps and other impurities from the powder recovered after a print (unsintered powder from the print bed with the powder remaining in the source and overflow container).

An industrial quality device and a size of 60 x 34 x 30cm with a capacity of 5 liters of powder volume. The small powder sieve is the ideal complement for the Lisa 3D printer from Sinterit.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy