3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

The Inkbit Vista™ printing system features impressive dimensional accuracy and highly functional material properties, and is designed for high throughput at production scale.

The Inkbit Vista™ printing system is designed for mass production of 3D printed polymer components. It utilizes Vision-Controlled Jetting (VCJ) technology, which provides high-resolution print quality and allows users to print components with high precision and dimensional accuracy in large quantities.

Inkbit Vista™ manufactures parts with support structures made of wax that can be easily thermally dissolved after the printing process. This gives you unmatched design freedom and the shortest production times.

Key advantages:

- High dimensional accuracy

- Functional materials

- High quantities

- Short production times

- The best 3D printed components that can be produced according to the current state of technology

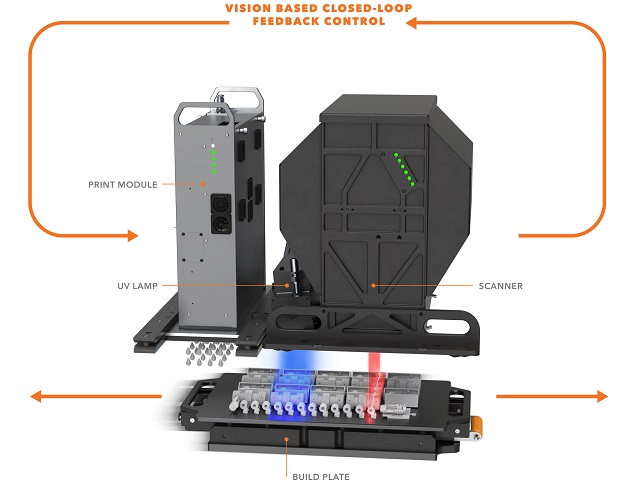

VCJ is a 3D printing process that uses InkJet printheads to deposit the material and optimizes the control of the printheads using high-quality scanners and image processing. After each layer is deposited, Inkbit Vista creates a topographic map of that layer using a proprietary 3D scanning process. The geometry of the initial part and the scan data of each layer are combined to optimize the application of the next layer. Thanks to real-time dynamic layer generation, parts are always produced quickly and accurately.

Closed-loop feedback control based on image processing ensures that printed parts always correspond exactly to the original CAD design.

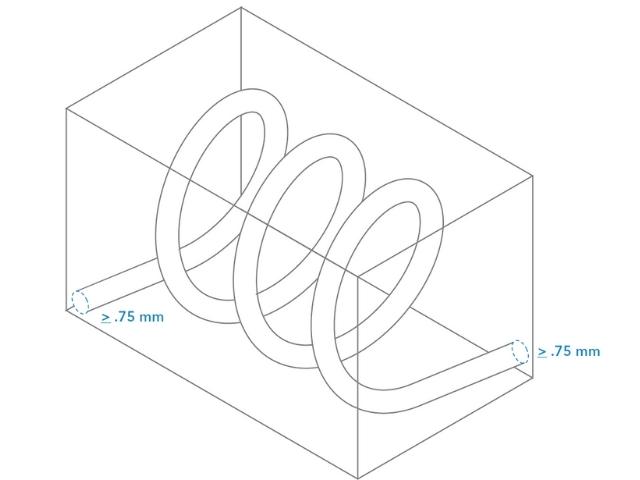

The Inkbit Vista™ printing system can print any geometry as long as it fits within the build volume of 490 x 245 x 200 mm, whether it is a single part or an entire series.

Resins developed by Inkbit have excellent mechanical, chemical and thermal properties. These persist over a long service life. Many of the limitations that exist with conventional additive manufacturing technologies are eliminated by VCJ, allowing Inkbit's production system to process materials with the desired properties for the end application. Inkbit is able to develop materials that meet a wide range of consumer requirements, including elastomers that can be stretched by up to 180% or high-performance polymers that can withstand temperatures of up to 130 °C.

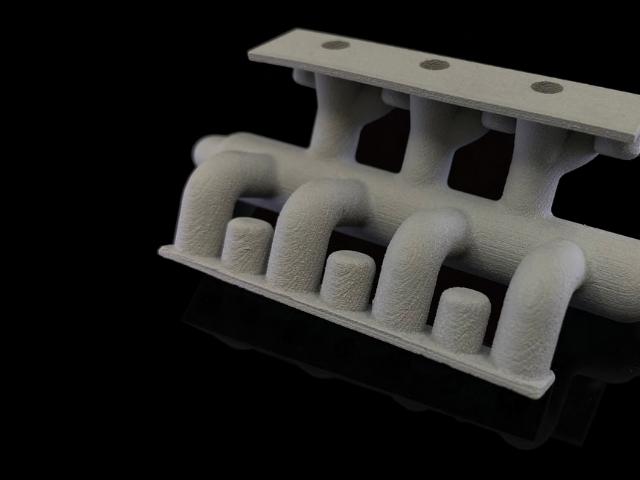

By using fusible wax as a support material, designers are not limited to straight channel geometries. For example, serpentine, intersecting or spiral canals can be produced. Thus, there are no limiting constraints on the design process.

Production applications requiring low cost per part are enabled by the automatable post-processing and the recyclable support material.

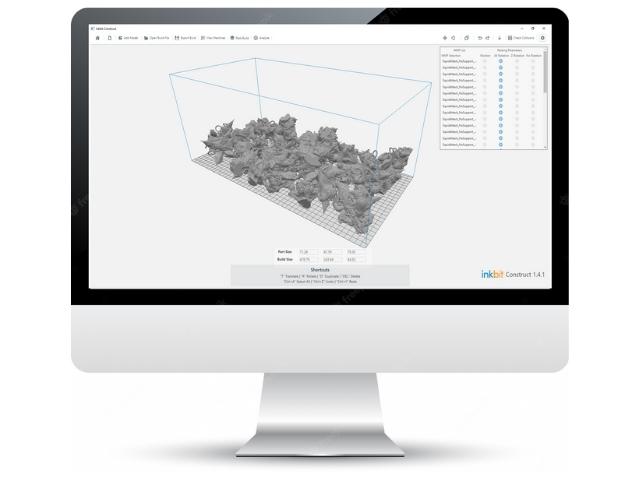

Inkbit's "Construct" software includes a proprietary nesting algorithm that enables fast and efficient print job preparation even for many models (>100) with high facet counts (>10M).

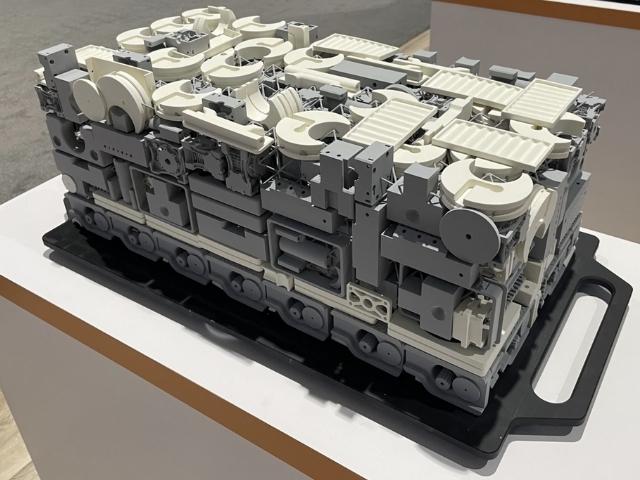

VCJ has the unique ability to produce parts with minimal pitch (<1mm), enabling printing with very high packing densities (>30%).

The Inkbit Vista™ printing system can image usable threads up to M2 and high-precision fits.

VCJ can also produce components from up to three different materials in the same print job. This allows applications with different material requirements to be processed overnight in a single print job.

The Inkbit Vista™ printing system has minimal space requirements. The production system requires no dedicated space and can be unloaded and restarted in as little as 2 minutes, providing high uptime.

Rethink the way industrial automation equipment has been designed and manufactured. With the Inkbit Vista™ printing system, simplify and redesign traditionally machined and molded assemblies to improve performance and reliability. Integrate pneumatic circuits and create soft contact surfaces.

The design of manifolds for fluid handling is complex and subject to many constraints. The Inkbit Vista™ printing system enables the geometric freedom of 3D printing while providing highly chemical resistant materials with greater durability than other additive manufacturing solutions on the market.

Do you need soft components? Eliminate injection molding tooling costs and save time by printing directly on the Inkbit Vista printing system with functional elastomer materials. Inkbit Vista™ prints soft, silicone-like parts with intricate and complex features at production speed.

Unleash engineering creativity with production-scale additive manufacturing on the Inkbit Vista™ printing system. Inkbit Vista offers unparalleled production capacity and higher part quality with fast and automated post-processing. Inkbit's materials remain consistent over long periods of time, enabling long-life production applications.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy