3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

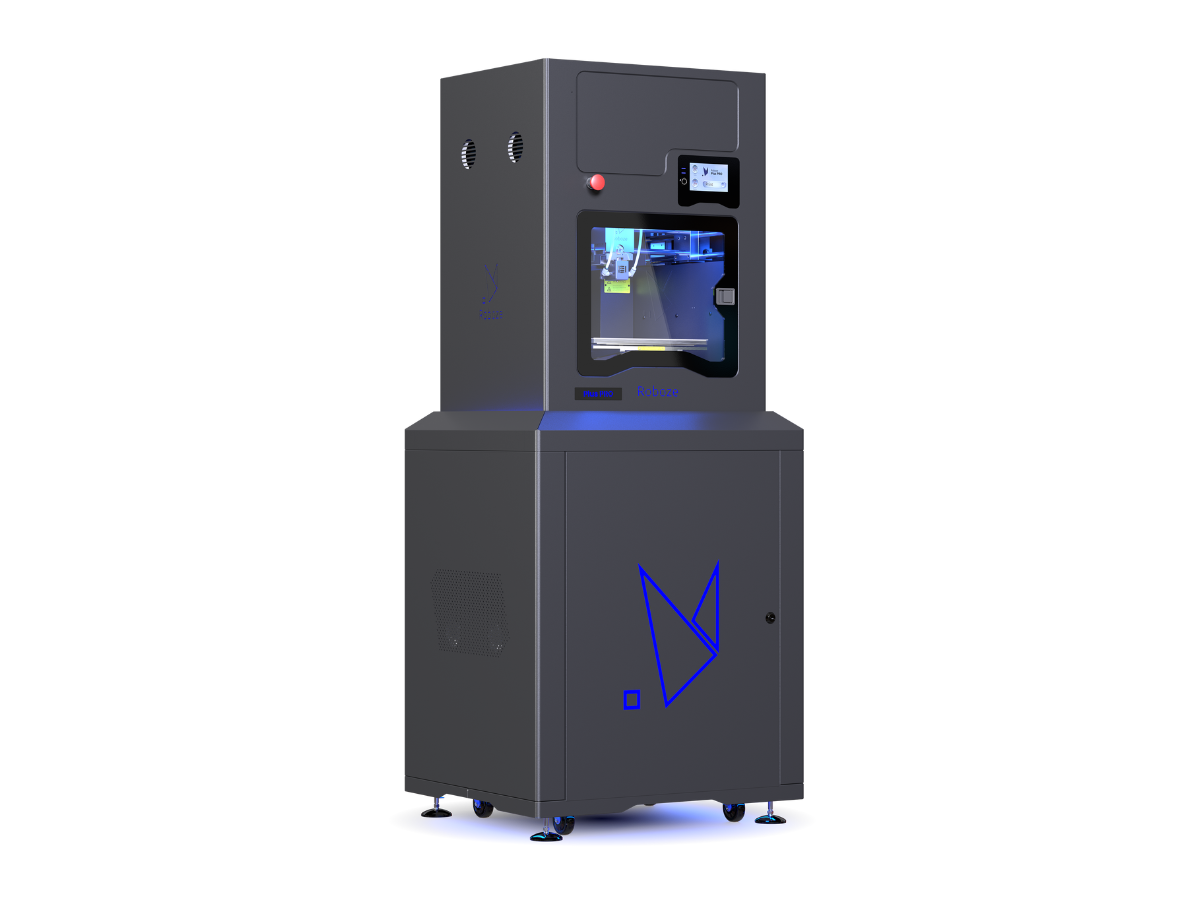

Accelerate your product development by using advanced materials. Create parts with a positioning accuracy of 15 µm with reliable quality, using the 3D printer.

The Roboze Plus PRO is an industrial high-temperature 3D printer from the Italian manufacturer Roboze. With its extruder that can reach up to 450°C and a build plate that is heated up to 150°C, the Plus PRO is compatible with superpolymers and composites such as PEEK, Carbon PEEK, Carbon PA, PEKK, ToolingX CF, PP, Flex-TPU, FUNCTIONAL-NYLON, Strong-ABS, ABS-ESD, and ULTRA-PLA.

Technical data:

Construction volume: 300 x 250 x 220 mm

Accuracy: XY:15µm ; Z:25µm

Print profiles: High-Definition profile, Ultra-High-Definition profile, Standard profile, Speed profile.

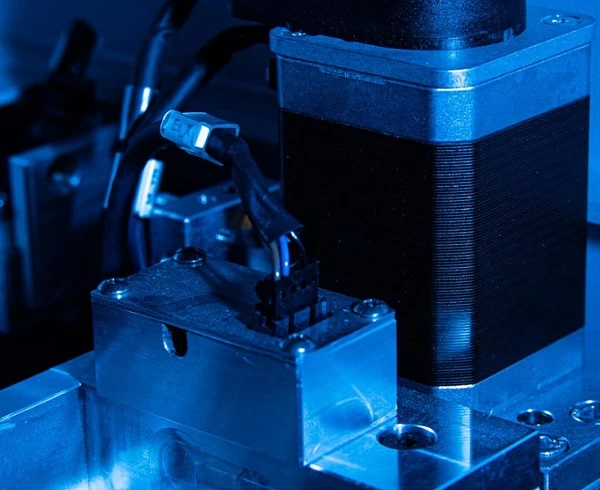

Roboze's beltless system has long been associated with accuracy and repeatability. The Roboze Plus PRO promises a pressure accuracy of XY: 15 μm.

The Roboze Plus PRO has a build volume of 300 x 250 x 220mm (11.8 x 9.8 x 8.7in), making it slightly larger than the One Pro.

The Plus PRO's extruder is capable of higher temperatures, reaching up to 500 °C / 932 °F compared to the One Pro. The print bed also reaches higher temperatures, up to 150 °C / 302 °F compared to the One Pro.

With motors equipped with encoders that automatically correct any errors, the Roboze Plus PRO ensures accuracy and repeatability in movement.

Both the One PRO and Plus PRO achieve accuracies of XY: 15 μm /5 90.55 μin and Z: 25 μm /9 84. 25 μin.

The Plus PRO has four print profiles for different applications, one more than the One PRO, - High-Definition-Professional, Ultra-High-Definition-Professional, Standard Profile, and Speed Profile.

To ensure complete control over the condition of the machine, Roboze Plus PRO is equipped with sensors for automatic material loading and detection of possible irregularities.

The Plus PRO can process polymers such as carbon PEEK, PEKK, PEEK, TOOLINGX CF, carbon PA, functional nylon, and many others.

Roboze does not use improvised techniques to adhere the parts to the plate, but polymer films that are chemically compatible with the applied materials. The film can be reused several times and can be easily modified.

The HT dryer is integrated into the PRO series industrial 3D printers. Together with the other state-of-the-art components of the machine, it is used to prepare the material before 3D printing, drying, and heating it. This ensures the surface quality and mechanical resistance of the manufactured parts.

Using ULTEM AM9085F, Roboze technology has been able to produce cup holders that save up to 71% of costs.

By using carbon PA instead of metal, a centering device was developed that reduced the number of parts in the bearing by 92%.

By using PEEK, Roboze technology, 39% of costs could be saved in the production of bus bar holders.

By using carbon PEEK instead of specially alloyed brass, gears could be produced and their weight reduced by 84%.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy