3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

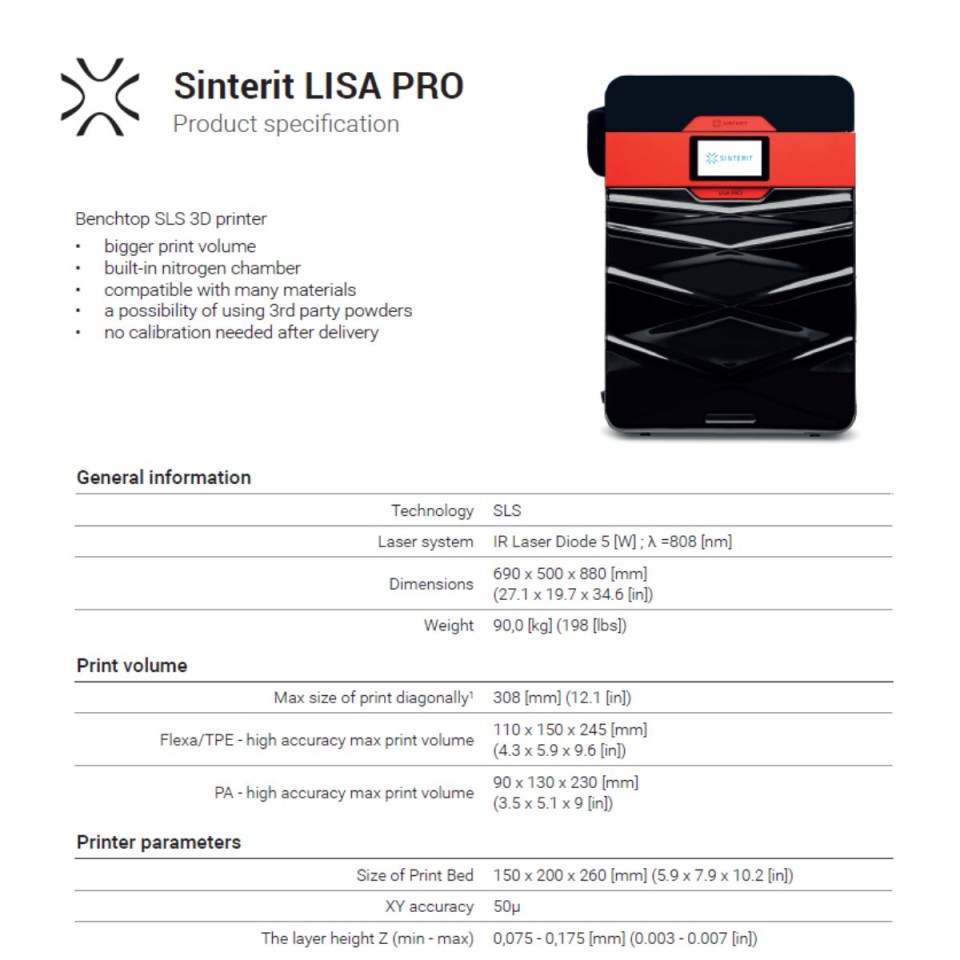

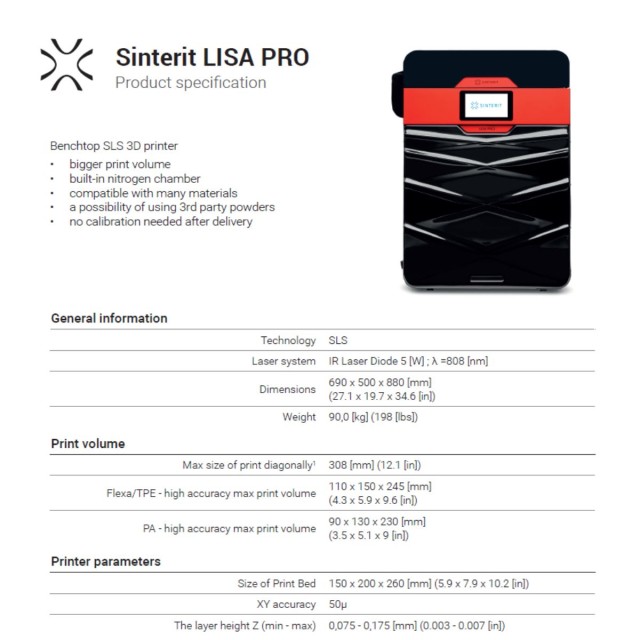

The Sinterit Lisa Pro system is the best way to learn about the potential of selective laser sintering, whether for prototyping or low-volume production, materials research, or in-house training for engineers and designers.

The Sinterit Lisa Pro 3D printing system allows the most complex designs to be created in one piece, without support structures, using selective laser sintering.

Technical data:

Build volume: 110 x 160 x 245 mm

Maximum printing diagonal: 313 mm

Building speed: 3 mm/h

Laser type: IR 5 W

For each individual Sinterit material, a pressure profile has been carefully developed to guarantee you the best possible component quality.

Nevertheless, Sinterit offers you the freedom to adapt these parameter sets individually for your application.

The Sinterit Lisa Pro offers a print bed size of 150x200x260 mm, an XY accuracy of 0.05 mm, and a Z layer height of 0.075 to 0.175 mm.

It has a print speed of up to 3 mm/h.

Using the open sintering software, you can individually set up to 32 different print parameters and create user-defined profiles.

The powerful heating system has independently adjustable heating zones.

This guarantees homogeneous heat distribution in the installation space, even at temperatures of up to 200 °C.

Choose from a wide portfolio of flexible or even extremely resistant materials for your creative creations.

You can switch between materials in half an hour.

It features an advanced 7-inch interactive LCD touchscreen, built-in camera, and WiFi/USB connectivity.

Produce stable parts for the end user or investigate the portfolio of their products in terms of feasibility using additive manufacturing.

Generate components that meet their stability or complexity requirements in countless applications.

Do away with unnecessarily expensive warehousing and produce the spare parts you need directly on-site.

Verify your design before going into production. Test form, fits, and function with an accurate model of your final product.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy