3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Fill up the form below and we will send you the data sheet by e-mail.

Fill up the form below and we will send you the data sheet by e-mail.

Fill up the form below and we will send you the data sheet by e-mail.

Fill up the form below and we will send you the data sheet by e-mail.

Fill up the form below and we will send you the data sheet by e-mail.

Grippers are widely used for pick and place operations in automated production lines. Grippers have component-specific contours at their ends that enable them to pick up, grip, transport or guide components. Current grippers are machined out of Aluminium, Bronzal or special Steel alloys. This process requires long labor time for each customized geometry. Thanks to 3D Printed grippers, pick and place operations can be more efficient due to customized geometries and increased wear resistance.

Fill up the form below and we will send you the data sheet by e-mail.

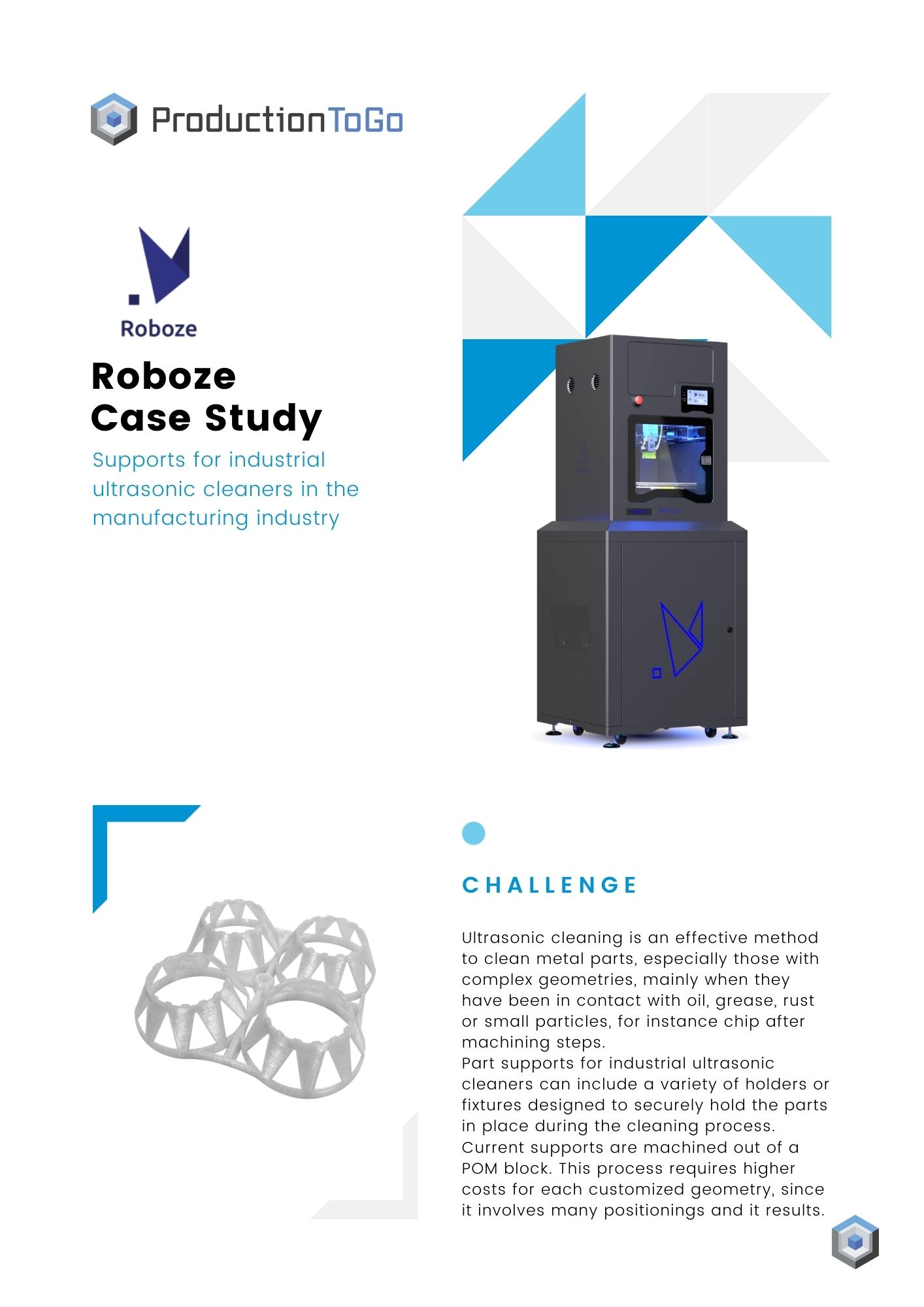

Ultrasonic cleaning is an effective method to clean metal parts, especially those with complex geometries, mainly when they have been in contact with oil, grease, rust or small particles, for instance chip after machining steps. Part supports for industrial ultrasonic cleaners can include a variety of holders or fixtures designed to securely hold the parts in place during the cleaning process. Current supports are machined out of a POM block. This process requires higher costs for each customized geometry, since it involves many positionings and it results.

Fill up the form below and we will send you the data sheet by e-mail.

Although the traditional artisanal thermoforming process is easy, it shows a huge limit: the production of the mold. Since they are hand-made by bending and welding together sheet metal and rods, manufacturing a single mold can occupy a resource up to two entire days. Batches of bent pipes can number between 10 and 30 individual pipes, meaning that each one needs its own mold. This means that for a single batch of 30 identical pipe configurations, two months of work are needed to manufacture all the molds.

Fill up the form below and we will send you the data sheet by e-mail.

|

|

Photos from the event |

|

|

On-demand webinar |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy