3D printers

High quality 3D printers

This blog post is not intended to be an all-encompassing collection of knowledge for Additive Manufacturing with filaments, but rather a brief compendium of the most important features and functionality of this technology.

3D printing with filaments is not the oldest, but clearly the best-known Additive Manufacturing process. If you enter the keyword "3D printing" in any search engine, you will primarily find results on filament 3D printers, whether it’s information, images or shopping ads.

This is partly due to the fact that almost the entire hobby segment in 3D printing consists of filament 3D printers. Nowadays there are also some resin 3D printers for the hobbyist market, but there is no thought of filament Additive Manufacturing being displaced in this segment.

However, it would undoubtedly be inappropriate to assign filament 3D printing exclusively to the hobby segment. The popularity of this technology is not only because it virtually fills the hobby segment alone - Additive Manufacturing with filaments also offers unique advantages and many different areas of application in the professional and industrial segment.

Before we get to that I'd like to briefly explain the process behind 3D printing with filaments first. Because despite the widespread awareness of this technology, it can still be a bit ambiguous to some people how to additively produce a complete part. We will now clear up this ambiguity!

First of all, what is a filament in 3D printing? A filament is a thread-like thermoplastic that can deform within a certain temperature range, which varies depending on the type of thermoplastic. When heated, the filament melts, and when cooled, it solidifies again. This deformation is reversible in thermoplastics - the filament can therefore undergo this process several times as long as it does not overheat.

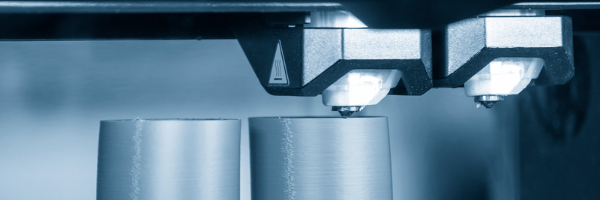

This deformation of the filament plays an essential role in 3D printing with filaments. The filament is fed into the build chamber of the respective printer, where it is heated to its melting temperature and then extruded layer by layer onto the build plate through one or more metal nozzles.

To protect the components from slipping and to ensure maximum stability, the build plate or the entire build room should be heated. Even temperature distribution on the build plate or in the build room is of utmost importance to prevent warpage!

This process is called either Fused Deposition Modelling (FDM) or Fused Filament Fabrication (FFF). Both terms refer to the same process, but Fused Deposition Modelling and the associated acronym are protected trademarks of the American-Israeli company Stratasys®.

Obviously Stratasys® is not the only manufacturer of filament 3D printers. The filament 3D printer market almost certainly has the largest selection of manufacturers within Additive Manufacturing. For this blog post, however, I'll limit myself to the major manufacturers of professional and industrial filament 3D printers.

Since the company name has come up several times now, the American-Israeli company Stratasys® should also start this listing of filament 3D printer manufacturers.

The company, founded in 1989, has both PolyJet, SLA and FDM machines in its product range. Filament 3D printers include, for example, the professional F123 series and the industrial Fortus 450mc.

Raise3D, which was founded in 2015 and is currently headquartered in the United States, has a large portfolio of professional filament 3D printers.

This portfolio includes the professional Pro2 and Pro3 series and the professional E2CF.

Markforged®, based in the United States, was founded in 2013 and was the first producer of 3D printers capable of printing continuous carbon fiber reinforcements.

Outside of that, Markforged® is known for its wide range of different filament 3D printers - including the professional Mark Two™ and the industrial X7™ and FX20™ 3D printers.

Founded in 2011 in the Netherlands, Ultimaker, which merged with U.S.-based MakerBot® in August 2022, already has a sizable portfolio of filament 3D printers, despite being founded not too long ago.

These include the professional S Series and the professional Method Series, originally developed by MakerBot®.

INTAMSYS, short for INTelligent Additive Manufacturing SYStems, was founded in Shanghai in 2016 and now has two additional locations, Germany and the United States, to support global sales of its filament 3D printers.

These 3D printers include the professional FUNMAT HT and the industrial FUNMAT PRO 610HT, among others.

Founded in Italy in 2015, Roboze's mission is to take polymer processing to a new level. The company achieves this with several professional and industrial filament 3D printing systems.

Professional equipment includes the Pro series, while industrial requirements are covered by the ARGO series.

A big advantage of this category of Additive Manufacturing is also the reason why it is so widespread in the hobby segment - the low acquisition costs. For hobby use, you can sometimes find decent filament 3D printers for just over 100 euros, and even professional 3D printers can be found for as little as 5,000 euros, which is unbeatably cheap compared to other categories of 3D printing.

The material costs also hold up very well in terms of price, at least on average, compared with other categories. For example, while 1 kg of resin often costs over 50, and not infrequently even over 100 euros, filaments are usually available for under 50 euros per kg. However, this does not include high-performance filaments such as PEEK, which are much more expensive.

Around the materials, the extraordinarily large selection must also be mentioned. There are an indescribable number of filament types, from ABS to PET and PEEK to TPU. This large selection of materials enables components with a wide variety of properties. Whether chemical resistance, heat resistance, elasticity, ESD capability, break resistance or much more - there are filaments that have these properties.

Another advantage that explains the widespread use of filament 3D printers is their ease of use. With few exceptions, such as ABS, no toxic materials, no mandatory post-processing outside of support removal, and easy material handling make Additive Manufacturing with filaments the most user-friendly process within 3D printing.

Last but not least, the high speed of filament 3D printers must also be emphasized. Even professional printing systems can now boast speeds of up to 350 mm/s, which can massively reduce production time, whether in the professional or industrial sector - although it must be mentioned that higher speeds always have an impact on surface quality.

Like any other production method, filament 3D printing also has some disadvantages. The extent to which these come into play is very individual, but it is nevertheless essential to know them so as not to be blindsided after the purchase.

Probably the biggest disadvantage of this manufacturing method is the lower surface quality, at least compared to other 3D printing technologies. In the vast majority of cases, the surface quality is rather rough, which can be improved with a little sandpaper, but this takes considerably more time.

The level of detail also lags behind other technologies in Additive Manufacturing with filaments. Unfortunately, this disadvantage cannot be corrected by post-processing, which is why filament 3D printing is simply not suitable for components that require very high detail accuracy.

Despite the ease of use of filament 3D printers, there is always one problem - clogged nozzles. Cleaning them is not particularly complex, but it leads to a complete production stop every time. Depending on the frequency, this can cost quite a bit of money as well as nerves.

The last disadvantage I would like to mention is the rather limited design freedom. While with other Additive Manufacturing methods, especially metal 3D printing, the design freedom knows virtually no limits, with filament 3D printing you have to live with a major restriction - the wall thickness must always be above one millimeter in order to obtain a stable end product. This makes components that require a wall thickness below this minimum impossible with filament 3D printing.

3D printing with filaments is now present in many industries, where it takes on a wide variety of tasks - from prototypes to series components.

One of the most important applications of Additive Manufacturing with filaments is in the aerospace sector. With the ability to produce lightweight and low-cost components using industry-certified materials such as ULTEM or PEEK, filament 3D printing manages to reduce costs for both construction and operation, thanks to reduced fuel consumption through lighter components, within the aerospace industry.

The automotive industry also uses Additive Manufacturing with filaments. It can be used to produce prototypes very cost-effectively and quickly, allowing a wide range of iterations to be produced and tested in a much shorter time.

Thanks to ESD filaments, the electronics industry is now also benefiting from 3D printing with filaments. These enable cost-efficient production of components, faster customization and compliance with ESD standards.

But it is not only industry that is coming into contact with filaments more and more frequently - in our everyday lives, too, we can find more and more products that originate partly or completely from Additive Manufacturing with filaments. Decorations, coat hooks, vases, sporting goods and much more that we use more or less every day can now be produced using filament 3D printing.

Hopefully this blog post was able to make it clear that the popularity of filament 3D printing is not solely due to its great use in the hobby printer sector, but also thanks to its unique features and the ability to produce quality products at a much lower cost and less time.

However, this high profile now does not mean that this technology can rest on the laurels it has already received. Other Additive Manufacturing processes are becoming more and more well-known and quick progress is taking place throughout Additive Manufacturing.

In filament 3D printing, this progress is primarily material-related. High-performance materials that can at least improve, if not eliminate, some of the drawbacks of this manufacturing technology are becoming more common, and more 3D printers capable of processing these materials are appearing on the market.

If you are interested in marveling at the latest information on filament 3D printing with your own eyes, I can recommend a visit to a showroom.

Otherwise, I hope that this introduction to filament Additive Manufacturing has been able to help you get an overview of this technology and its possibilities.