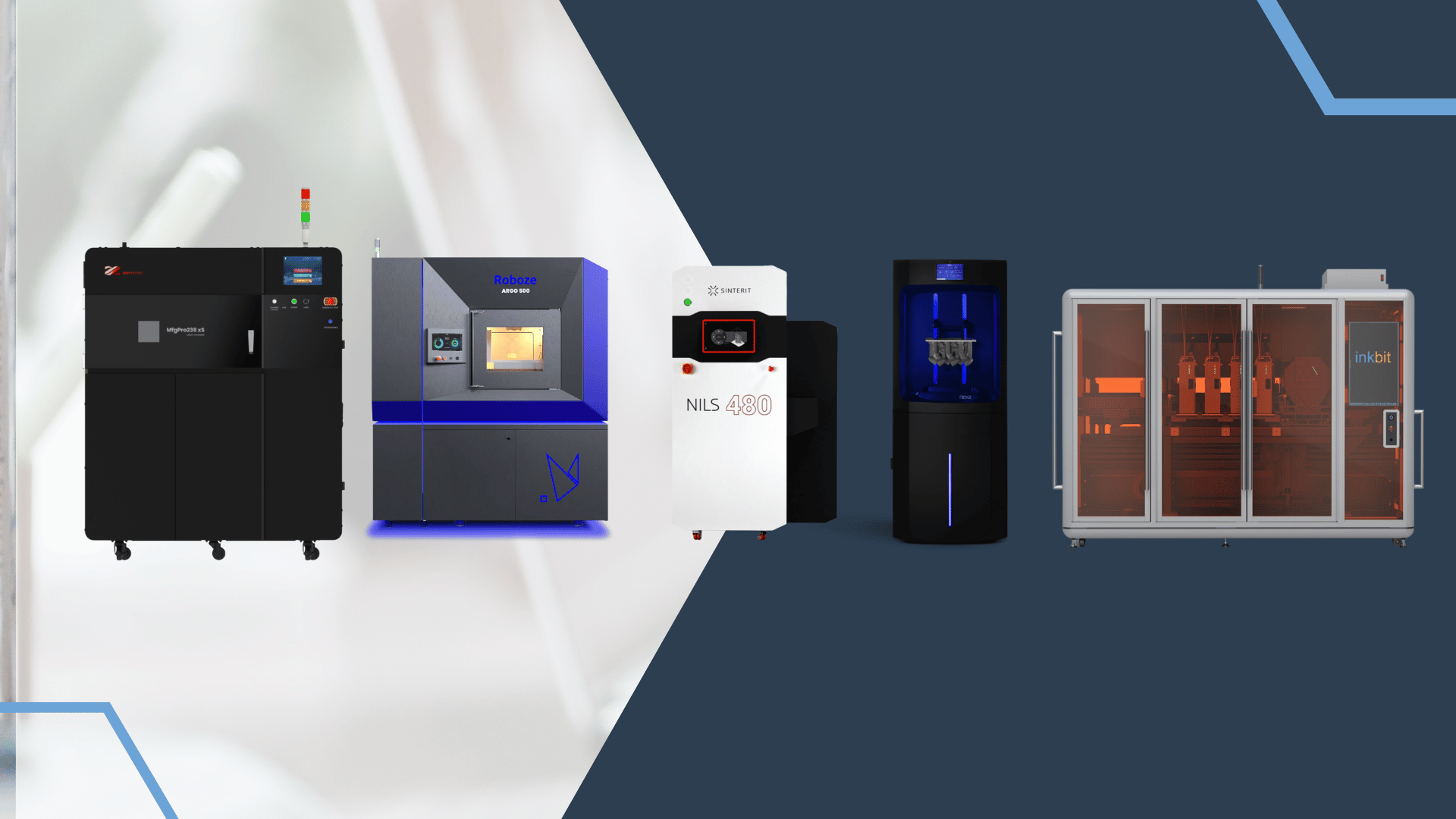

3D printers

High quality 3D printers

|

OPEN HOUSE: ProductionToGo Benelux |

Photos from the event |

|

Nexa3D® Road Show – Cologne (Germany) |

|

|

Nexa3D® Road Show – Munich (Germany) |

|

|

The road to making the right decision for an industrial 3D printer in 2023 |

On-demand webinar |

|

Hoe de effectiviteit van een 3D-printer nog verder vergroot kan worden |

Read more |

|

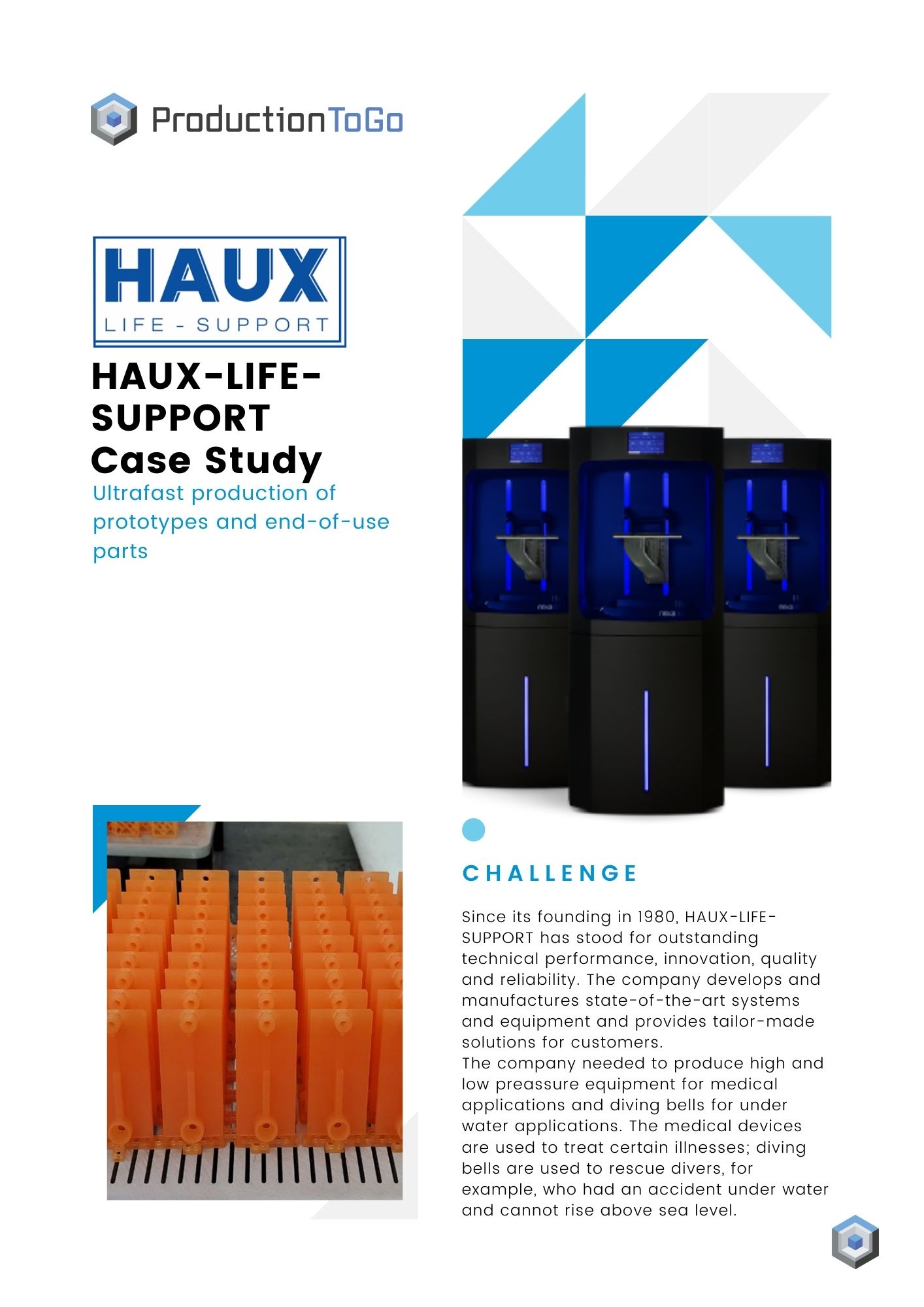

Additive Manufacturing in Medicine - How 3D Printing can save Lives |

Read more |

|

Additive Manufacturing with Resin - Introduction |

Read more |

|

The possibilities of Additive Manufacturing in the industry |

Read more |

|

How Additive Manufacturing is revolutionizing the automotive industry |

Read more |

|

Product development with the help of 3D printing |

Read more |

|

3D printing and the benefits for aviation |

Read more |

|

Mobility of the future - Additive Manufacturing in the automotive industry |

Read more |