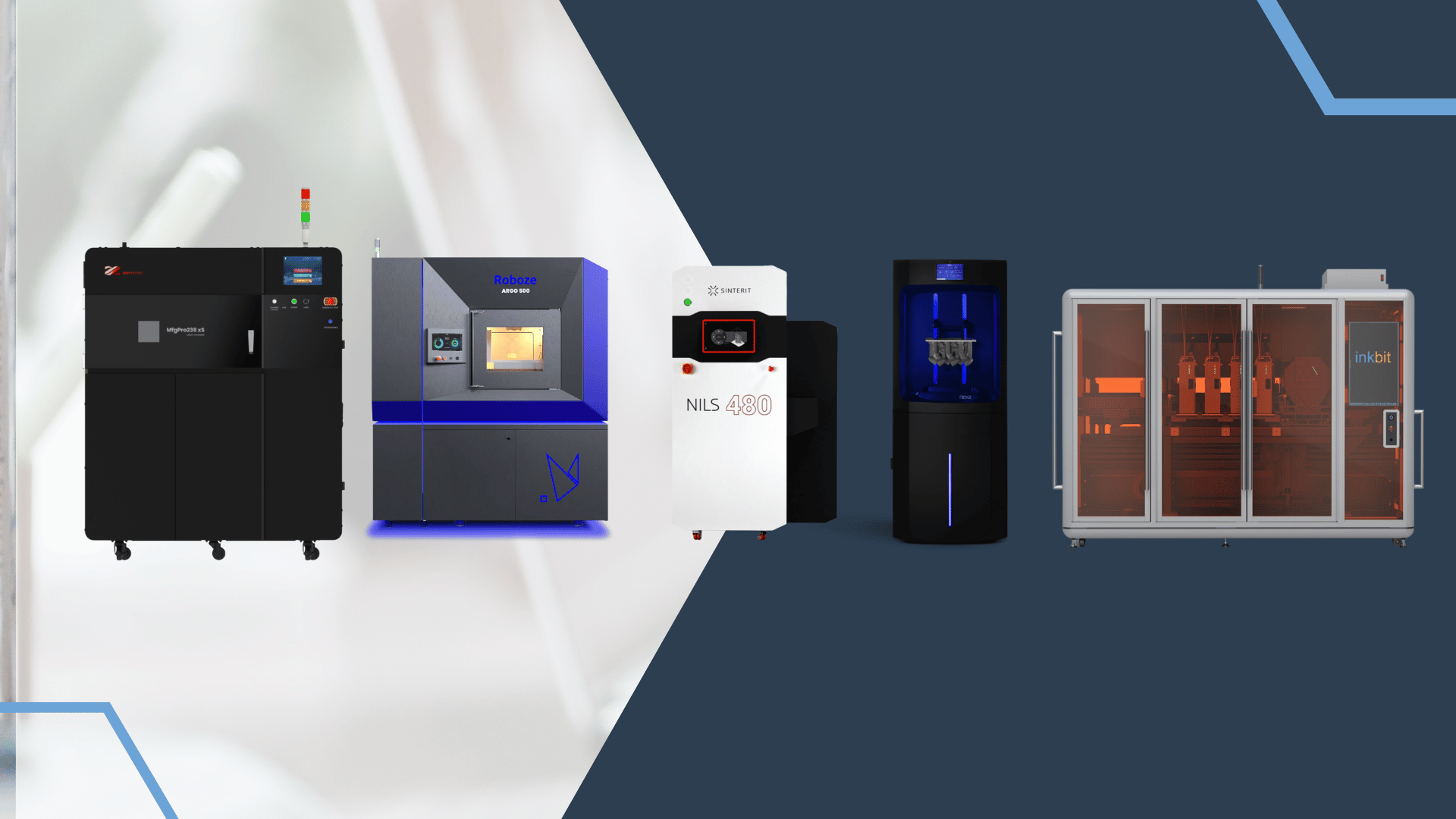

3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Fill up the form below and we will send you the data sheet by e-mail.

During the first few weeks of the COVID-19 pandemic, 3D Printing Tech received a call from a local Doctor and Lab Owner with a simple question, “Can you 3D print nasal swabs for COVID testing?” A group had formed involving a number of high profile universities and medical systems with the initiative of designing a 3D printed nasal swab.. SLA, MJF, and even FDM/FFF were methods others were pushing for the swabs, but 3D Printing Tech, fully understanding the scalable capabilities of SLS printing, decided to push forward in that direction.

Fill up the form below and we will send you the data sheet by e-mail.

Azoth has developed a new way of manufacturing indirect materials through their TAKE ONE MAKE ONE system. Building on lean manufacturing principles, TOMO™ aims to fully optimize the inventory management process by eliminating waste and reducing the cost to carry inventory. With TOMO™, a digital copy of the physical inventory is created which Azoth uses to manufacture custom parts on-demand via 3D printing. In other words, when a user takes one product out of inventory Azoth manufactures one to replace it. This system drastically decreases inventory levels and allows engineers to iterate their designs with little to no obsolescence.

Fill up the form below and we will send you the data sheet by e-mail.

A robot requires fitted tools to complete the duty for which it is called upon. These tools are called end of arm tools, which in many cases are multiple pneumatically actioned claws or grippers, attached to a bracket of the required shape. Interest was shown to reduce the weight of gripper brackets that are to be utilized by the robots. An optimized part was produced in a SLA printer, but the resulting component wasn’t as rigid as what was hoped for. A solution was sought after to maintain the lightweight design, but to ensure a component with similar stiffness to that of the initial part.

Fill up the form below and we will send you the data sheet by e-mail.

Global supply chains had been interrupted for weeks. Millions of urgently needed protective equipment for medical staff, such as FFP2/FFP3 breathing masks, had been ordered worldwide, but doctors in Germany had not received all orders. This certainly created insecurity among doctors, surgeons and nurses. What will happen to patients, when we are no longer able to carry out operations due to the lack of suitable breathing masks and filters? What will the situation be like in Germany in a few weeks’ time? On April 3, 2020, Dr. Markus Pietsch from Helios medical center in Hildesheim dealt with those thoughts.

Fill up the form below and we will send you the data sheet by e-mail.

HELLA Automotive has been developing and manufacturing vehicle lighting for over 100 years. Recently, they began developing an LED headlamp replacement for police and emergency vehicles, and identified two problems with existing replacements that were on the market: 1. The warning lights on emergency vehicles do not function when the flashing lights are enabled. 2. The procedures for installing the alternative headlamp can lead to costly mistakes for the installers, such as drilling errors and poor silicone seals that can damage the vehicle.

Fill up the form below and we will send you the data sheet by e-mail.

Like many Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF) users, JawsTec had to forgo usage of 30% of their thermoplastic powder, while also bearing the cost of its storage and disposal in accordance with regulations. This waste of end-of-life powder not only raised the company’s operating overhead and impacted profit, but also represented a significant environmental issue for a company committed to sustainable manufacturing. JawsTec was looking to raise their additive manufacturing output, streamline costs and enhance company sustainability by significantly lowering the waste ratio of sintering powders used.

Fill up the form below and we will send you the data sheet by e-mail.

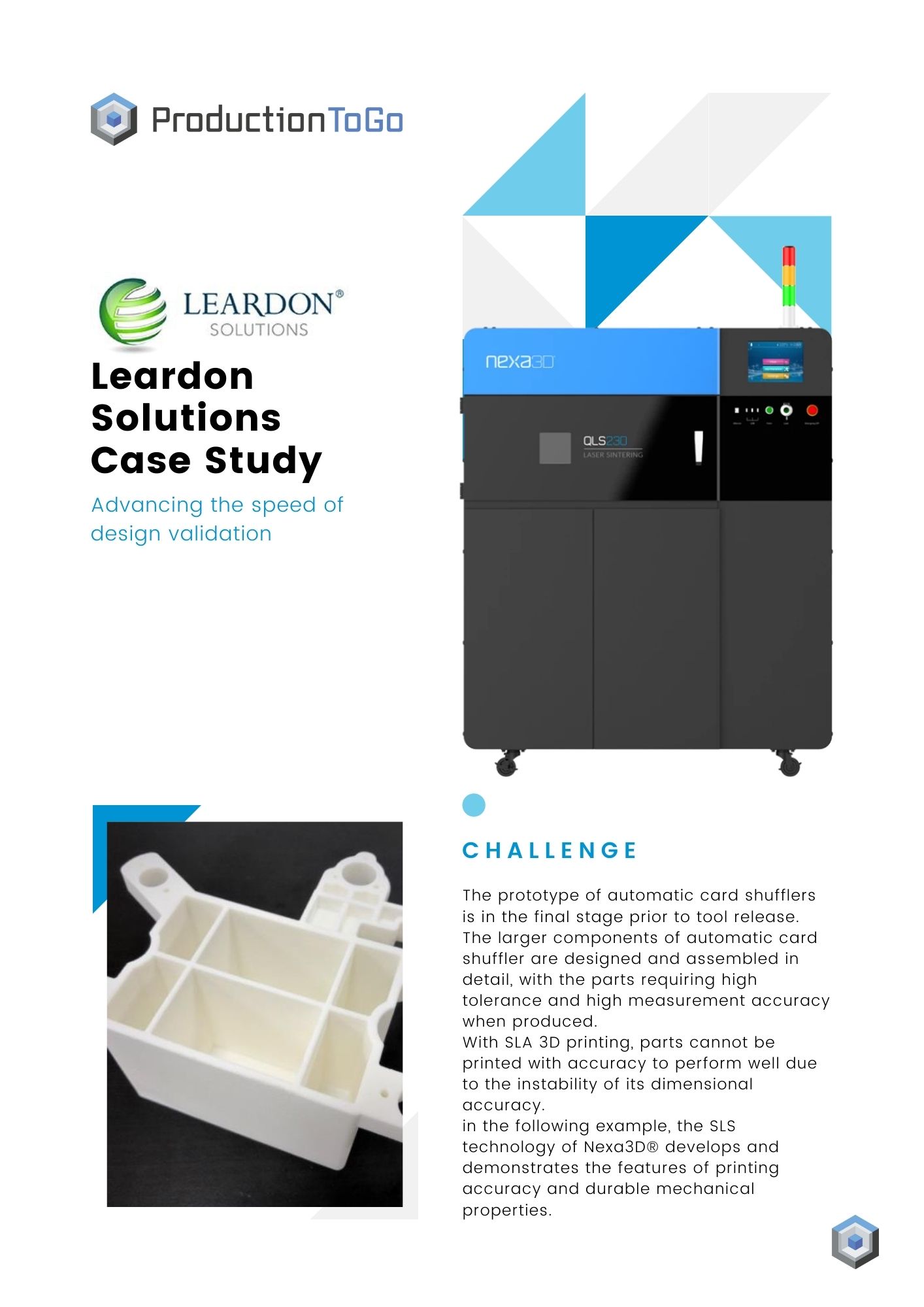

The prototype of automatic card shufflers is in the final stage prior to tool release. The larger components of automatic card shuffler are designed and assembled in detail, with the parts requiring high tolerance and high measurement accuracy when produced. With SLA 3D printing, parts cannot be printed with accuracy to perform well due to the instability of its dimensional accuracy. In the following example, the SLS technology of Nexa3D® develops and demonstrates the features of printing accuracy and durable mechanical properties.

Fill up the form below and we will send you the data sheet by e-mail.

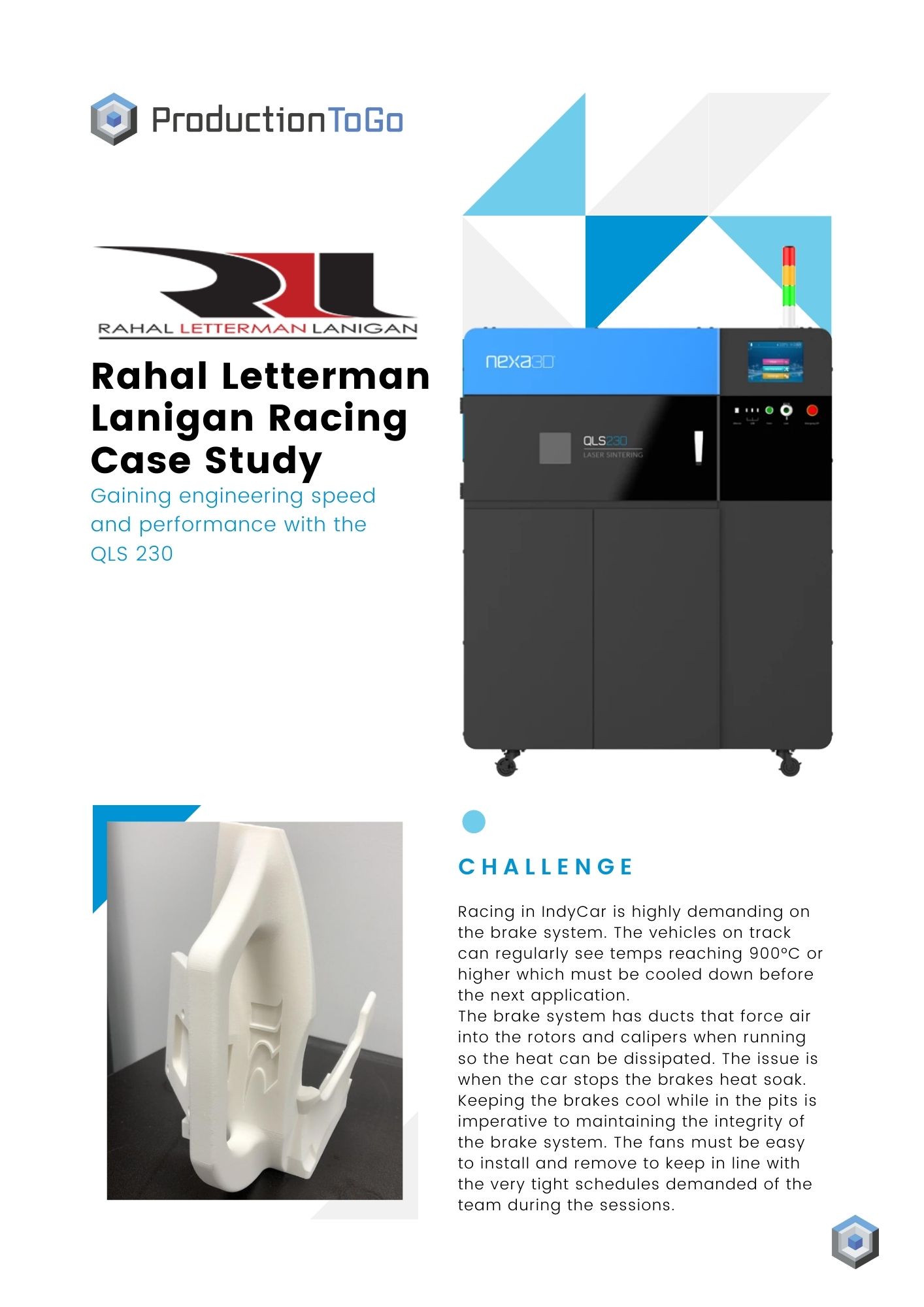

Racing in IndyCar is highly demanding on the brake system. The vehicles on track can regularly see temps reaching 900°C or higher which must be cooled down before the next application. The brake system has ducts that force air into the rotors and calipers when running so the heat can be dissipated. The issue is when the car stops the brakes heat soak. Keeping the brakes cool while in the pits is imperative to maintaining the integrity of the brake system. The fans must be easy to install and remove to keep in line with the very tight schedules demanded of the team during the sessions.

Fill up the form below and we will send you the data sheet by e-mail.

TrySight develops various hardware and software solutions to help those with low vision and blindness. In this niche market production runs are relatively low. Additionally, design changes to parts are frequent. This combination made traditional tooling methods uneconomical. To address this challenge, TrySight was using FDM 3D Printing for over 5 years. But the quality of the parts TrySight was producing using FDM did not meet dimensional tolerances, strength or temperature resistance for end-use. Labor and material costs were significant due to high print failure rates and a two-dimensional build area which only allowed a few parts to be printed at a time.

Fill up the form below and we will send you the data sheet by e-mail.

Shiruba is a prestigious aquarium filter manufacturer which was founded in 1980. The company has abundant experience in research and development, original Design Manufacturer (ODM), and agency business for 30 years. The complicated geometry and precision required for these filters make prototyping assemblies a challenge. A conventional approach of prototyping such designs with CNC machining, would be cost and time prohibitive for iterative verification and limit the creative development. However Selective Laser Sintering (SLS) provides high efficiency and design customization advantages.

Fill up the form below and we will send you the data sheet by e-mail.

|

|

Photos from the event |

|

|

|

|

|

|

|

|

|

|

|

On-demand webinar |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

|

|

Read more |

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy