3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

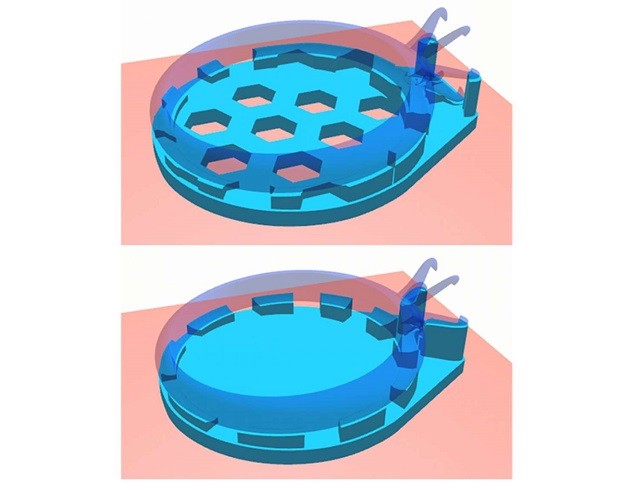

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

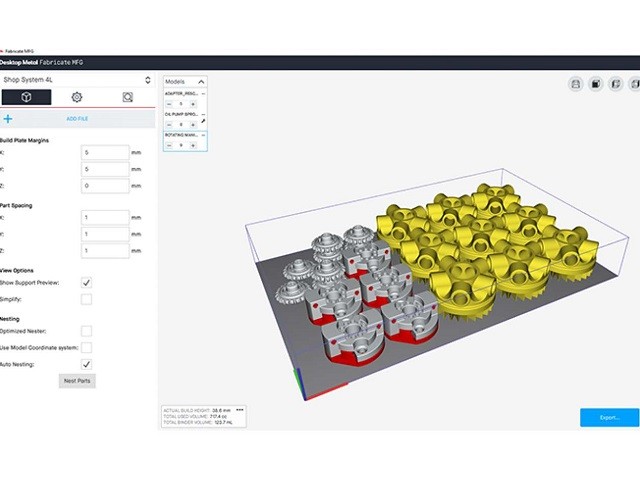

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

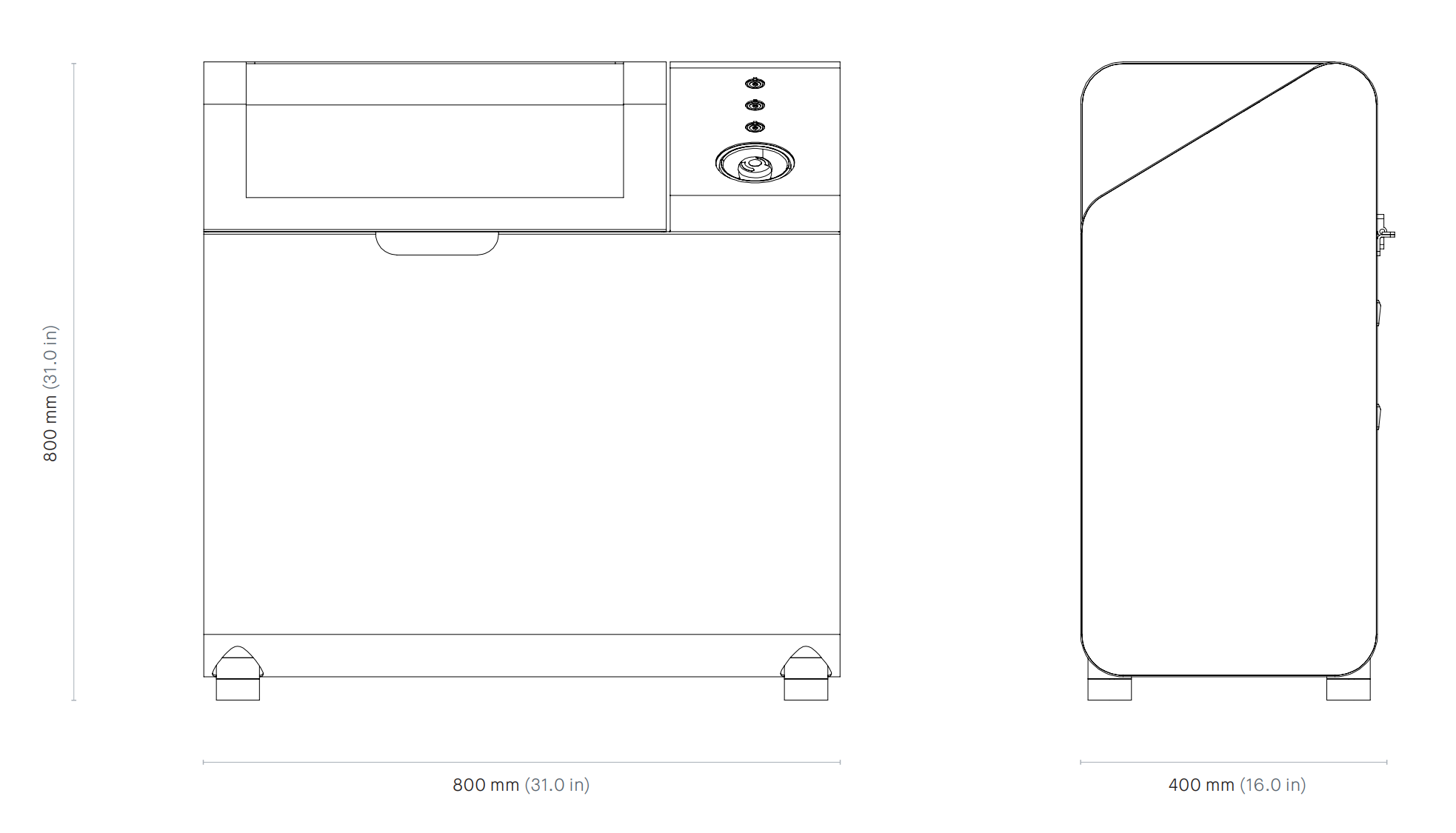

The printer first lays and homogenizes the fine metal powder before precisely spraying on the binder, thus firmly defining the part geometry. The printer reliably processes the stored data layer by layer until the predefined installation space is completely filled.

When printing is finished, the kit is removed and placed in the powder station. Here, the loose powder is removed and recovered via a built-in powder recycling system with powder sieving.

The "green compacts" are then positioned in the tray of the furnace and sintered according to predefined / stored temperature curves. This allows a fine microstructure with high mechanical properties to be achieved. The furnace reaches a temperature of up to u 1400 ºC.

After completion of the green body, the entire kit is removed from the printer and placed in the drying oven. During this process, the remaining moisture in the binder escapes and the binder hardens. The solid component can now be cleaned of the remaining powder with ease.

When preparing the powder, a small amount of fresh powder is added to the residual powder. In the Powder Blender of the Shop System™, rotating paddles then mix the powder mixture, breaking up any agglomerates and ensuring homogeneity.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy