3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Compared to conventional production methods and laser-based additive manufacturing, the Shop System™ from Desktop Metal® is an end-to-end solution. It uses single-pass binder jetting 3D printing technology to produce high-resolution 3D printed parts quickly and cost-effectively.

The Desktop Metal® Shop System™ is designed to easily increase your productivity. Increase your capacity without adding additional personnel. The system is designed for modern batch production and is easy to use. Print your parts, more cost-effectively and with better surface quality, compared to laser-based technologies.

With the turn-key solution from Desktop Metal®, consisting of printer and peripherals, you can get started immediately.

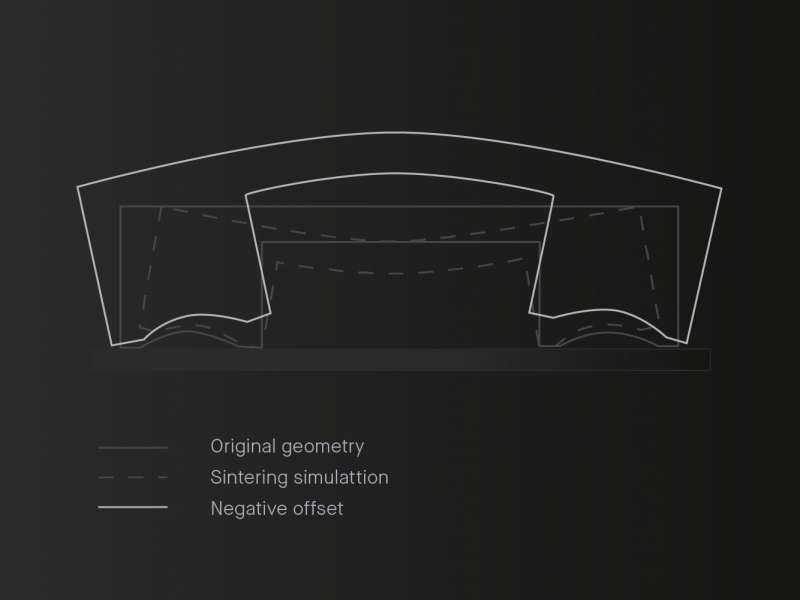

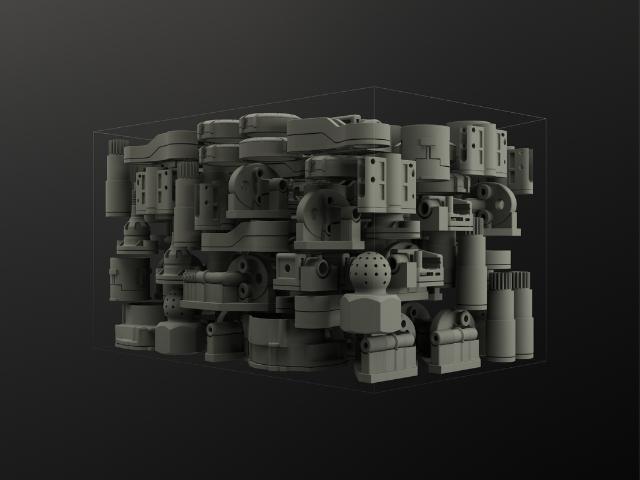

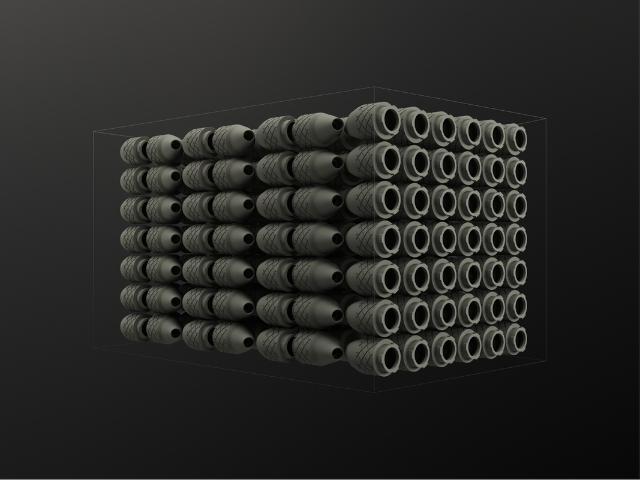

By means of different build space configurations (4L, 8L, 12L and 16L), you can optimally adapt the throughput of the printer to your needs.

The Desktop Metal® Shop System™ features a single-pass printhead, with the highest resolution in the world. This sprays approximately 670 million drops/second, guaranteeing high-speed printing, with a droplet distribution of 1600x1600 dpi.

(33% more than the nearest competitor).

The Desktop Metal® Shop System™ guarantees a 10-fold increase in printing speed compared to laser-based processes. At the same time, the system processes 700 ccm³/hour and guarantees an output of approx. 70 Kg/day.

Print your high-quality products with unsurpassed part quality, quickly and cost-effectively.

Users no longer have to sacrifice high resolution or detail for speed. With the Desktop Metal® Shop System™, print detailed parts with exceptional surface quality at maximum speed.

The smallest droplet size used in the industry is sprayed on (1.2 pL) and automatically adjusted via the software up to 6 pL.

The Desktop Metal® Shop System™ has more than 70,000 nozzles distributed over five rows. Printing problems caused by nozzle failures are thus avoided. Compared to other 3D printing systems, the printhead has 25% more nozzle redundancy, improving print quality and reliability.

The Desktop Metal® Shop System™ uses a tool-less manufacturing process.

Complex and diverse components can be manufactured at the touch of a button using the plug-and-play principle, without costly set-up times.

In the Desktop Metal® Shop System™, components are automatically manufactured with removable support structures.

These serve as sintered supports and, unlike laser-based processes, do not have to be removed mechanically.

A protective layer prevents the material bonding of the component with the so-called "raft" and thus enables simple, non-machined removal of the supports.

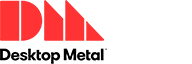

The unique Live Sinter software, has solved the long-standing problem of shrinkage and warpage of parts. Using various algorithms, the program calculates and simulates the resulting stresses and warpage of the part during sintering and automatically generates the off-set model in advance.

Desktop Meta® offers the ultimate "turn-key solution" for your production with the Shop System™. Configure the appropriate build volume (4L, 8L, 12L and 16L) of your components as needed to increase your efficiency many times over. Build volume configurations with expandable capacities that can be customized as needed.

The printer first lays and homogenizes the fine metal powder before precisely spraying on the binder, thus firmly defining the part geometry. The printer reliably processes the stored data layer by layer until the predefined installation space is completely filled.

When printing is finished, the kit is removed and placed in the powder station. Here, the loose powder is removed and recovered via a built-in powder recycling system.

The "green compacts" are then positioned in the furnace tray and sintered at up to 1400°C according to predefined / stored temperature curves. The resulting microstructure resembles an investment casting with high mechanical properties.

Call or email us and we will be happy to help you.

Manufacture different components at the same time, without any machine setup.

Cost-effective solution for smaller batches with complex geometries.

Process-reliable series production with almost unlimited design freedom.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy