3D printers

High quality 3D printers

Powder-based 3D printing has long been a go-to for producing complex metal parts. But is it always the best choice?

With the rise of alternative technologies like Meltio’s wire-laser Directed Energy Deposition (DED), it’s time to take a closer look.

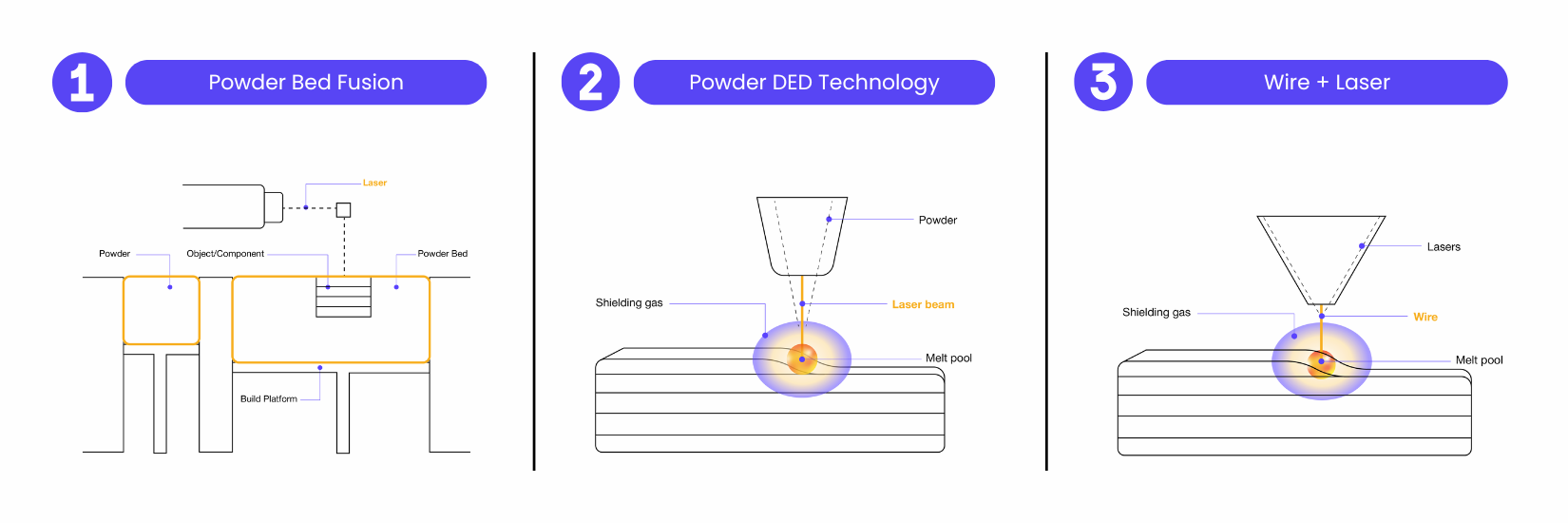

This blog compares powder-based additive manufacturing methods, mainly Powder Bed Fusion (PBF) and Powder Directed Energy Deposition, with Meltio’s wire-laser DED approach.

While these powder-based methods offer unique benefits, they also come with significant challenges.

To really get the most out of powder-based 3D printing, it’s important to understand the challenges that come with it. Meltio’s wire-laser DED approach helps address some of these issues and offers its own set of advantages.

Powder Bed Fusion (PBF) has quickly become one of the leading methods in additive manufacturing, especially popular in engineering and biomedical fields. What sets it apart is its ability to build parts layer by layer from a single material, making it ideal for producing complex geometries and custom designs that meet precise industrial requirements.

Powder DED technology is one of the earliest and most versatile additive manufacturing methods that feeds raw powder directly into a laser’s focal point. The laser melts the powder, creating a molten pool that solidifies into layers. A motion control system guides the deposition, building the part layer by layer in free space, allowing the entire process to be seen as the part gradually takes shape.

Meltio’s wire and laser technology is driving innovation across various industries by offering a cost-effective and highly efficient solution for producing complex metal components. As a Directed Energy Deposition (DED) process, it enables the precise layering of weld beads, creating strong, durable parts with faster production times. This breakthrough combination of wire feedstock and laser energy is making waves in aerospace, automotive, energy, and tooling industries, where the demand for customized, high-performance metal parts is growing.

In aerospace, for instance, it allows for the creation of lightweight, high-strength components that meet stringent quality standards. In automotive, the technology is being used for rapid prototyping and on-demand production of spare parts. In energy sectors, Meltio’s wire and laser technology is being utilized for repairing high-value components, extending their lifespan while reducing costs. The ability to produce these components efficiently with minimal material waste is also contributing to sustainability efforts across industries, making Meltio’s approach a key player in the evolution of advanced manufacturing.

As the demand for advanced manufacturing solutions continues to grow, Meltio's wire and laser DED technology offers a new perspective. Let's explore the distinct advantages that make this approach stand out in the world of additive manufacturing

1. Continuous deposition:

The constant flow of wire feedstock during the DED process keeps the build running smoothly without interruptions, driving efficiency and slashing production time. With no need for frequent stops or manual adjustments, the process becomes a seamless, streamlined operation from start to finish.

2. Large-scale applications:

This unique combination shines when it comes to crafting large-scale components, thanks to its continuous feed and minimal reliance on support structures. It enables the efficient production of sizable parts, cutting down both production time and costs, making it a highly cost-effective solution.

3. Material waste reduction:

Wire-based additive manufacturing processes are designed with efficiency in mind, generating less material waste compared to powder-based methods. As the wire is only used when needed, there's little to no excess, translating to cost savings and a more sustainable production process.

4. Cost-effectiveness:

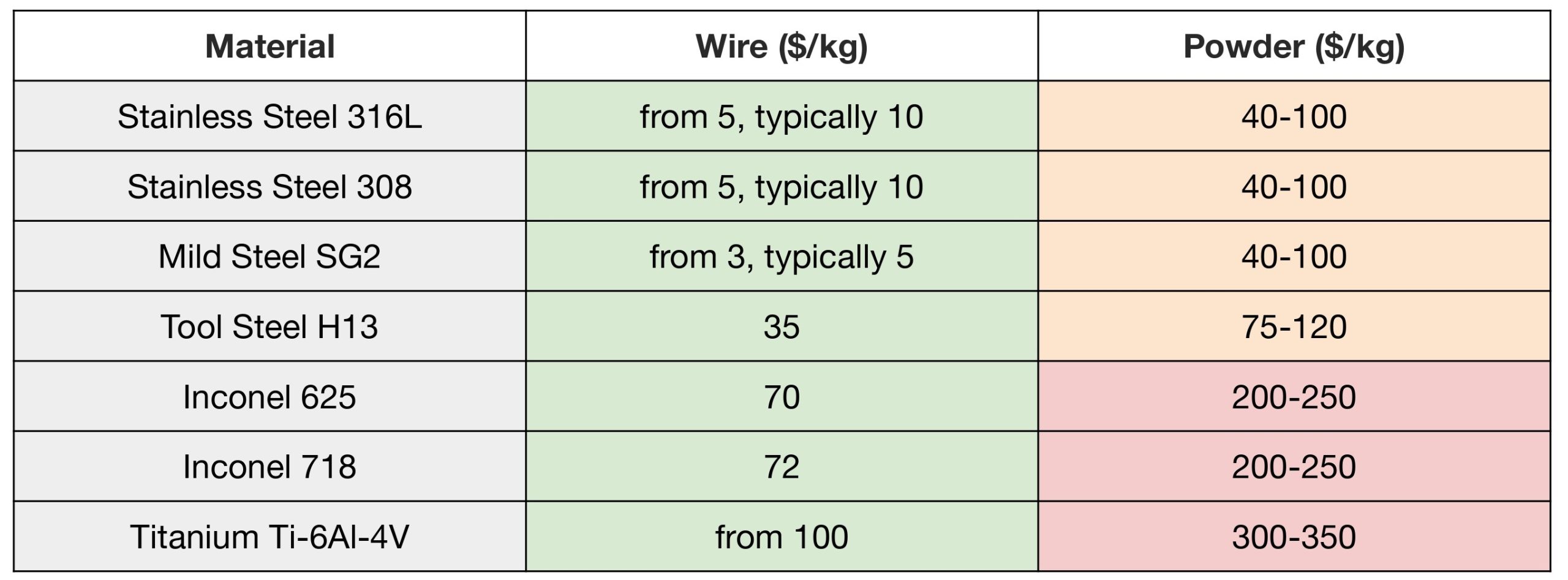

Wire feedstock offers a more budget-friendly option compared to powdered alternatives, with its production and handling being simpler and more economical. Easily sourced as a common welding material, wire is often a fraction of the cost of powders. With wire prices starting around $3.00 per pound, savings can reach up to 10 times, especially when working with certain alloys. This stark cost difference makes wire a highly attractive choice for businesses looking to optimize material costs.

5. Enhanced productivity:

It boosts efficiency and productivity, particularly in continuous deposition systems. With a steady wire feed, production flows without interruption, cutting down on downtime and maximizing overall output.

6. Reduced need for protective equipment:

Unlike powdered additive manufacturing processes, wire-based methods eliminate the risk of airborne particulates, creating a cleaner and safer environment. This can reduce the need for heavy protective gear, enhancing operator comfort while maintaining high safety standards.

7. Facility requirements:

Wire-based additive manufacturing processes present the advantages of facilities with limited space or specific infrastructure constraints. The simpler handling of wire feedstock requires fewer facility modifications.

8. Convenient storage:

Wire-based additive manufacturing shines in environments with limited space or specific infrastructure needs. The simplicity of handling wire feedstock means fewer modifications are required, making it a practical solution for facilities looking to optimize their space and resources.

9. Inventory management:

The organized form of wire feedstock makes inventory management a breeze. With wire, it’s easier to monitor stock levels and plan for timely restocking. Plus, wire has a longer shelf life than many powdered materials, ensuring it stays in top condition for longer, reducing waste and improving efficiency.

10. Reduced contamination risk:

Because the wire is solid and less prone to dispersion, it significantly reduces the risk of material cross-contamination. In contrast, powdered feedstock is more vulnerable to accidental mixing or spills, increasing the chances of contamination. To mitigate this, strict protocols are followed to thoroughly clean equipment when switching powders. Contamination in powder-based processes can disrupt the microstructure of parts, ultimately affecting their quality and performance.

11. Improved handling and transportation:

Wire feedstock is simple to handle and transport, thanks to its solid, structured form. Typically sold on spools or reels, it’s easy to load into the 3D printing system, streamlining the process and reducing hassle.

12. Simplified machine clean-up:

Wire-based additive manufacturing simplifies the post-production process, with minimal clean-up required compared to powder-based methods. With less residual material left behind, workspaces stay cleaner and more organized. This reduces the need for constant cleaning, allowing for a smoother, more efficient workflow with fewer distractions.

13. Material change:

With wire-based additive manufacturing, switching between materials is a seamless process. The ease of swapping wire types allows for the creation of a wide range of components without long interruptions, and even enables the printing of parts with dual-material combinations, opening up new possibilities for design and functionality.

14. Zero material waste:

Meltio’s dual wire metal deposition process seamlessly feeds wire into the melt pool coaxially, ensuring every bit of material is put to use. In contrast, powder-based methods can waste as much as 30% to 50% of the material, highlighting the efficiency of Meltio’s approach.

15. Enhanced microstructure:

Meltio’s laser process creates an incredibly small heat-affected zone (HAZ), ensuring minimal heat spreads to the layers beneath or the surrounding area of the melt pool. This precision leads to a refined microstructure, enhancing the overall quality of the printed part.

16. Controlled process:

Meltio’s LMD technology provides remarkable precision by guiding the wire directly into the melt pool in perfect alignment. As the wire melts at the substrate’s surface, it does so independently of the material flow, enabling a highly refined feedback system. This ensures a steady, controlled process that delivers consistent, high-quality results every time.

17. Meltio’s Deposition Head:

The design incorporates a coaxial wire feed, channeling the wire directly into the center of the melt pool. This clever setup guarantees uniform print quality in every direction, while the low optical density of the lasers contributes to a longer service life, making it as efficient as it is durable.

18. Dual Wire capability and multimaterial printing:

Meltio’s printhead features two independent wire feeders, making it possible to print with two distinct materials in one go. This opens the door to versatile applications like hard-facing and anti-corrosion coatings. With this dual-material capability, you get a seamless, quick, and eco-friendly solution for 3D printing. No risk of cross-contamination, just efficiency at its best.

Let’s take a closer look at how Meltio’s wire and laser technology stands out for its cost-effectiveness, offering an efficient, high-quality solution that delivers value across a range of applications.

In short, PBF, Powder DED, and Meltio each bring unique strengths to the table. PBF excels in precision for industries like aerospace and healthcare, but can be slow and costly for larger parts. Powder DED offers faster speeds and material versatility, ideal for big parts and repairs, though it’s not as precise as PBF. Meltio, however, stands out by allowing multiple materials in one print, offering unmatched flexibility for hybrid manufacturing. The best choice depends on your project's needs, balancing material, size, resolution, and cost for the perfect result.