3D printers

High quality 3D printers

This blog post is not intended to be an all-encompassing collection of knowledge for Additive Manufacturing with metal, but rather a brief compendium of the most important features and functionality of this technology.

Metal 3D printing has now gained a firm foothold in industrial manufacturing. Somewhat smiled upon by some at the beginning, metal 3D printing is now replacing more and more traditional manufacturing methods such as CNC milling, injection molding and many more.

It can be concluded from this that Additive Manufacturing with metal must offer some advantages. But this form of manufacturing is also not immune to disadvantages. However, before we look at these advantages and disadvantages, I would first like to take a brief look at the subtypes of this technology, how these subtypes work, and the manufacturers of metal 3D printers.

Metal 3D printing comes with more subtypes than any other technology within Additive Manufacturing. From "C" as in "Cold Metal Fusion" to "S" as in "Selective Laser Melting", there is a lot.

I will focus on the six main subtypes of metal 3D printing in this blog post. However, to get to these subtypes, it is first necessary to categorize them. Namely, the laser-based and the sinter-based printing processes exist.

As the name clearly suggests, all of the following printing processes work with a laser or electron beam. With this laser/electron beam, the metal powder is heated and thus fused. Therefore, this process does not require external sintering furnaces.

This type of metal 3D printing was the first way to produce metal components through Additive Manufacturing. This possibility was mainly needed to massively increase the speed of production of complex metal components, in contrast to conventional manufacturing methods.

This category includes Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM).

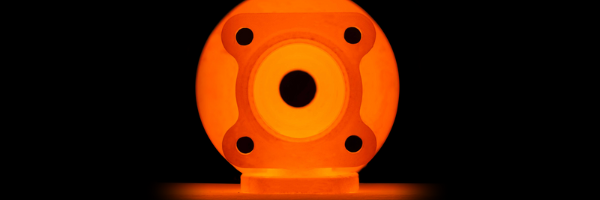

In Selective Laser Melting, a layer of metal powder, which is located on a powder bed, is completely remelted locally so that it forms a solid material layer after solidification.

The build plate is then lowered by the height of one layer thickness and powder is applied again. This cycle is repeated until all layers are remelted.

The finished component is then freed from powder residues and the support structures are removed. These support structures are always necessary in this process to keep the metal in the required shape due to its density and weight.

Direct Metal Laser Sintering is almost identical in process to Selective Laser Sintering - with one exception. In DMLS, the metal powder is heated only long enough for molecular fusion to take place, but not long enough to melt, as is the case with SLM.

This provides much greater material flexibility, but at the same time less durable mechanical properties than with SLM.

In Electron Beam Melting, which was developed by the US company Sciaky, conductive metal powder is first introduced into the printer and then the internal pressure in the build chamber is reduced, creating a vacuum. Once the ideal internal pressure is reached, the build platform is heated.

After reaching the required temperature, a layer of the metal powder is applied to the build plate and an electron beam, which is guided through electromagnetic coils, hits the powder at the right places to cause it to solidify.

The biggest advantage of EBM compared to SLM and DMLS is speed. Namely, the electron beam can separate to heat multiple locations of the metal powder simultaneously.

However, EBM offers less precision than the previously mentioned technologies. This is because the electron beam is wider than the laser beam, so accuracy is lost.

Sinter-based printing processes of Additive Manufacturing of metal are a further development of manufacturing processes originally developed for polymer parts. This process is used to manufacture green parts completely without tools and thus substitute injection molding in some capacity.

In each of these processes, a mixture of metal and polymer is used for printing. During printing, the polymer is formed into the green part and cured, while the metal powder initially remains "untouched". With the help of a sintering furnace, the polymer is completely thermally decomposed after printing, and the metal powder is hardened in the shape specified by the polymer.

It should always be noted that each component turns out smaller than the green part, which of course must be taken into account when creating the digital model.

This category includes Metal Binder Jetting (MBJ), Fused Deposition Modeling (FDM) with metal, and Cold Metal Fusion (CMF).

In Metal Binder Jetting, the print bed is covered with a layer of metal powder and a polymer binder is "speckled" onto the metal powder layer at the right places. This binder is cured by the temperature in the build chamber (approx. 70 °C). Once this curing is complete, a new powder layer is applied and the process is repeated until the green part is finished.

To avoid mechanical damage, the curing process usually takes place while the green part is embedded in the powder bed. Since the powder bed thus permanently serves as a carrier for the green parts, no additional support structures are necessary with this type of metal 3D printing.

Metal Binder Jetting offers excellent quality and precision, but is a somewhat lengthy process. While printing is relatively quick, the green part must be removed from the powder bed with brushes or compressed air and then sintered in an external furnace.

For these reasons, MBJ unfolds its full potential primarily in the series production of complex components.

Fused Deposition Modeling with metal works almost identically to 3D printing from filaments, although here the filaments consist of a certain percentage (usually 50 - 60%) of metal powder. The filament is fed via a spool through a heated printing extruder head, melted in it and then applied layer by layer to the build plate.

Components produced by this process always require support structures. However, these can also be formed from another material in printers with multiple extruders, making removal easier.

FDM with metal offers great user-friendliness thanks to simple operation and no powder handling, as well as low machine and material costs. Qualitatively, however, it is the weakest process in metal 3D printing, both in terms of surface quality and precision.

Cold Metal Fusion is the latest of the 3D printing processes presented here and was developed by Headmade Materials. In this manufacturing process, a mixture of metal powder and binder, mostly called "feedstock", is spot-irradiated by lasers to selectively harden the binder.

The build platform is then lowered and the next layer of feedstock is applied. This process is repeated until the green part is completed. The green parts are then freed from excess powder and sintered in an external furnace.

The attentive reader will already be familiar with this process description - this process is in fact very similar to Selective Laser Melting. The big difference is the much lower energy and cost required for printing, since unlike the SLM process, it is not the metal powder itself that is cured, but only the binder.

There are many different manufacturers around metal 3D printing. I will limit it here to the largest manufacturers for professional and industrial metal printing equipment.

The US company 3D Systems®, already mentioned in the blog post about Additive Manufacturing with resin, also manufactures 3D printers for metal in addition to their SLA printers.

The 3D Systems® metal portfolio consists of the industrial DMP Factory series and the professional DMP Flex series.

Founded in 2015, US-based Desktop Metal®, which despite its relatively short existence has already secured financial support from the likes of Google and BMW, manufactures several binder jetting and FDM metal 3D printers.

These include the X-Series and Production-Series industrial binder jetting systems, as well as the Fiber™, Shop System™ and Studio System™ 2 industrial FDM metal systems.

Concept Laser, a German company that is now part of the US conglomerate General Electric and its subsidiary GE Additive, is considered a pioneer of Powder Bed technology within Additive Manufacturing.

Concept Laser's products include the X Line 2000R and M Line industrial printing systems and the professional Mlab series.

Sciaky is a US company and with its foundation in 1939 one of the oldest companies around Additive Manufacturing. As mentioned earlier, Sciaky is the developer of the EBM process and is the only company to manufacture printing equipment using this technology.

Sciaky's portfolio includes the industrial EBAM 300-, one of the largest additive manufacturing systems in the world with a build envelope of nearly 5.8 meters in length, EBAM 150- and EBAM 68-series.

Taiwanese company XYZprinting, which was recently acquired in large part by Nexa3D®, manufactures industrial metal powder 3D printers at affordable prices.

These industrial metal powder 3D printers include the MfgPro236 xS, renamed QLS236 under Nexa3D® and MfgPro 230 xS, renamed QLS230 under Nexa3D®.

US-based Markforged®, which was founded in 2013, now also manufactures some metal 3D printers in addition to its diverse filament 3D printers.

These include the professional Metal X System™ and the industrial PX100™ printing system.

The greatest advantage of Additive Manufacturing with metal is the unlimited design freedom in combination with the possibility of manufacturing highly complex components. From the smallest details such as cavities and holes to the most diverse geometries - with metal 3D printing there are virtually no limits.

Another major advantage is the large selection of materials. Whereas in the past, stainless steel was virtually the only material available for producing metal components using Additive Manufacturing, a wide variety of metals with a wide range of properties are now available. Copper, aluminum, titanium, tungsten and many other metals can now be processed by 3D printing systems.

Metal components are needed mainly in industry. This is where the next advantage comes into play - the high production volume. In the vast majority of cases, metal 3D printing systems are capable of printing many, sometimes even different, components in a single run. In addition to the production of individual pieces, Additive Manufacturing with metal is therefore also ideal for series production.

Many of the metal Additive Manufacturing processes require support structures. This is normally a disadvantage, because they have to be removed from the finished part, which costs time and labor. However, with metal 3D printing, the support structures can usually be removed relatively easily with the help of suitable tools.

Last but not least, I would like to positively emphasize the isotropic microstructure. As a result, the mechanical and thermal properties are the same throughout the entire component, which means that the use of these components is no problem even under difficult conditions.

Of course, Additive Manufacturing with metal is not a supernatural gift without any flaws. Even such advanced technology unfortunately comes with some drawbacks.

Let's get the biggest of these drawbacks out of the way right now - cost. Metal 3D printers are, on average, the most expensive Additive Manufacturing equipment. Material costs are also mostly in the higher segment. In addition to the cost of printers and materials, there may also be the cost of sintering furnaces and other post-processing equipment.

This also brings us to the next disadvantage - post-processing. In the vast majority of cases, components from metal 3D printing have to be post-processed. Be it curing, grinding, support removal or much more - the end of printing is rarely also the end of the component.

As previously described, many of the metal printing technologies within Additive Manufacturing work with metal in powder form, making powder handling unavoidable. This ensures, on the one hand, that metal 3D printers mostly require a separate room so that the powder does not contaminate other work surfaces and, on the other hand, that industrial safety equipment is necessary for the use of the printer, which causes additional costs and requires trained employees.

Lastly, surface finish must be mentioned as a drawback. While this is in no way inferior, it is rougher than many other Additive Manufacturing processes. This makes metal 3D printing unsuitable for applications where very smooth or pliable surfaces are required.

Additive Manufacturing with metal has now proven to be an essential manufacturing method in many industries. The most important area of application, regardless of the industry, is the production of prototypes. Whether in the automotive industry, aerospace or consumer goods - 3D printing with metal makes fast and realistic prototypes possible.

Another area of application for Additive Manufacturing with metal is tooling. It enables the rapid production of tools with a high level of complexity and the problem-free replacement of tools as needed, reducing downtimes of production equipment and thus increasing the efficiency of production.

Medical technology also benefits from Additive Manufacturing with metal. Due to the mostly small quantities of implants, surgical aids and tools, for example, and the possibility of producing individual components faster than with any other manufacturing process, 3D printing with metal has now also established a foothold in this area.

Last but not least, the automotive industry must once again be mentioned as a major area of application - even outside of prototypes. Whether brake calipers, cooling jackets or engine parts, Additive Manufacturing with metal is rapidly becoming the standard for manufacturing within the automotive industry.

Additive Manufacturing of metal components brings many opportunities to the industry. Lower-cost components, tool-free green part production and greater self-sufficiency in production are just some of these. At the same time, however, it cannot be denied that some progress is still needed for the widespread application of this manufacturing technology.

The positive news here is that this progress is coming closer and closer in rapid steps. At the beginning, I mentioned that additive manufacturing with metal has more different subtypes than any other Additive Manufacturing technology. This is due to the continuous research and development of this manufacturing process - precisely to make it more widely available.

But this research and development also makes this manufacturing technology somewhat opaque. So much progress is coming that the overview of it can sometimes be lost.

If you want to be informed about the latest progress within this manufacturing technology, I can highly recommend a visit to a showroom or an exhibition. There you can be enlightened about many of these developments in the industry by experts and ask them questions.

Otherwise, I hope that this introduction to metal Additive Manufacturing has been able to help you get an overview of this technology and its possibilities.