3D printers

High quality 3D printers

Order high-quality 3D printed parts now at PartsToGo!

3D Print Now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Fill up the form below and we will send you the data sheet by e-mail.

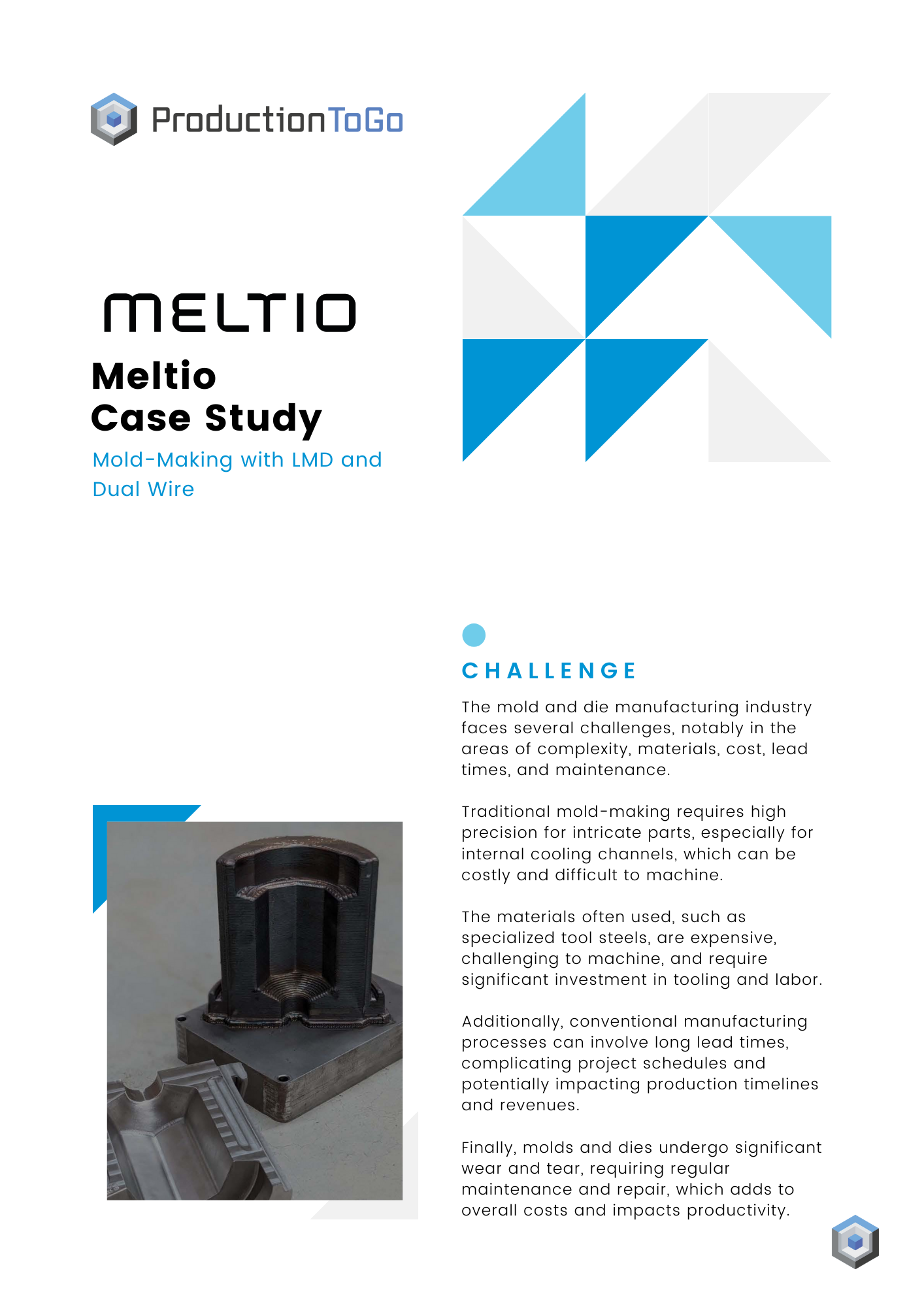

The die and mold industry faces several challenges, particularly in the areas of complexity, materials, costs, lead times and maintenance. Traditional mold making requires high precision for complicated parts, especially with internal cooling channels, which can be costly and difficult to machine. The commonly used materials, such as special tool steels, are expensive, difficult to machine and require significant investment in tools and labor. Furthermore, conventional manufacturing processes can involve long lead times, making project planning more difficult and potentially impacting production deadlines and revenues. Find out how Meltio's LMD technology solves these problems and increases efficiency in this application!

Fill up the form below and we will send you the data sheet by e-mail.

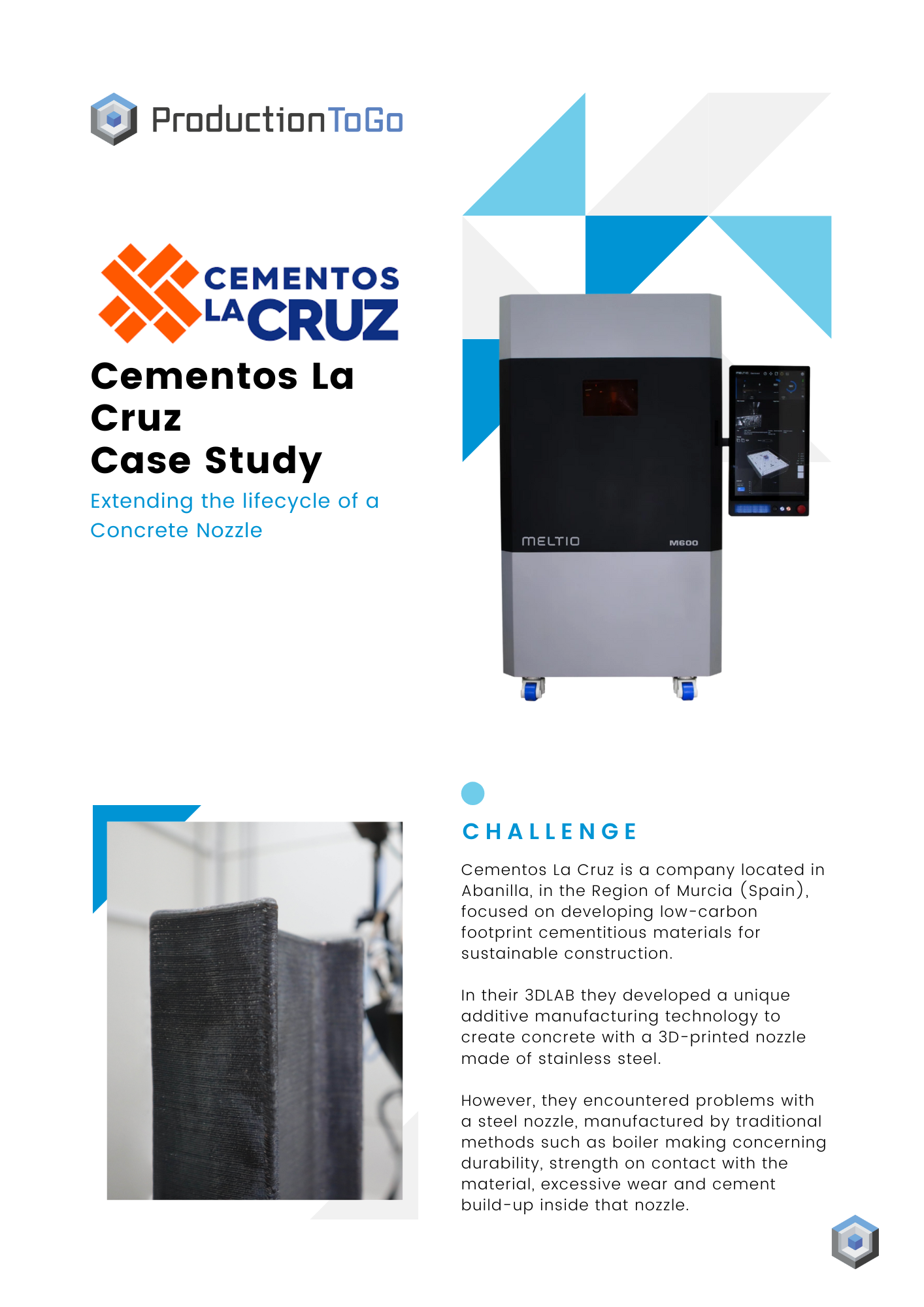

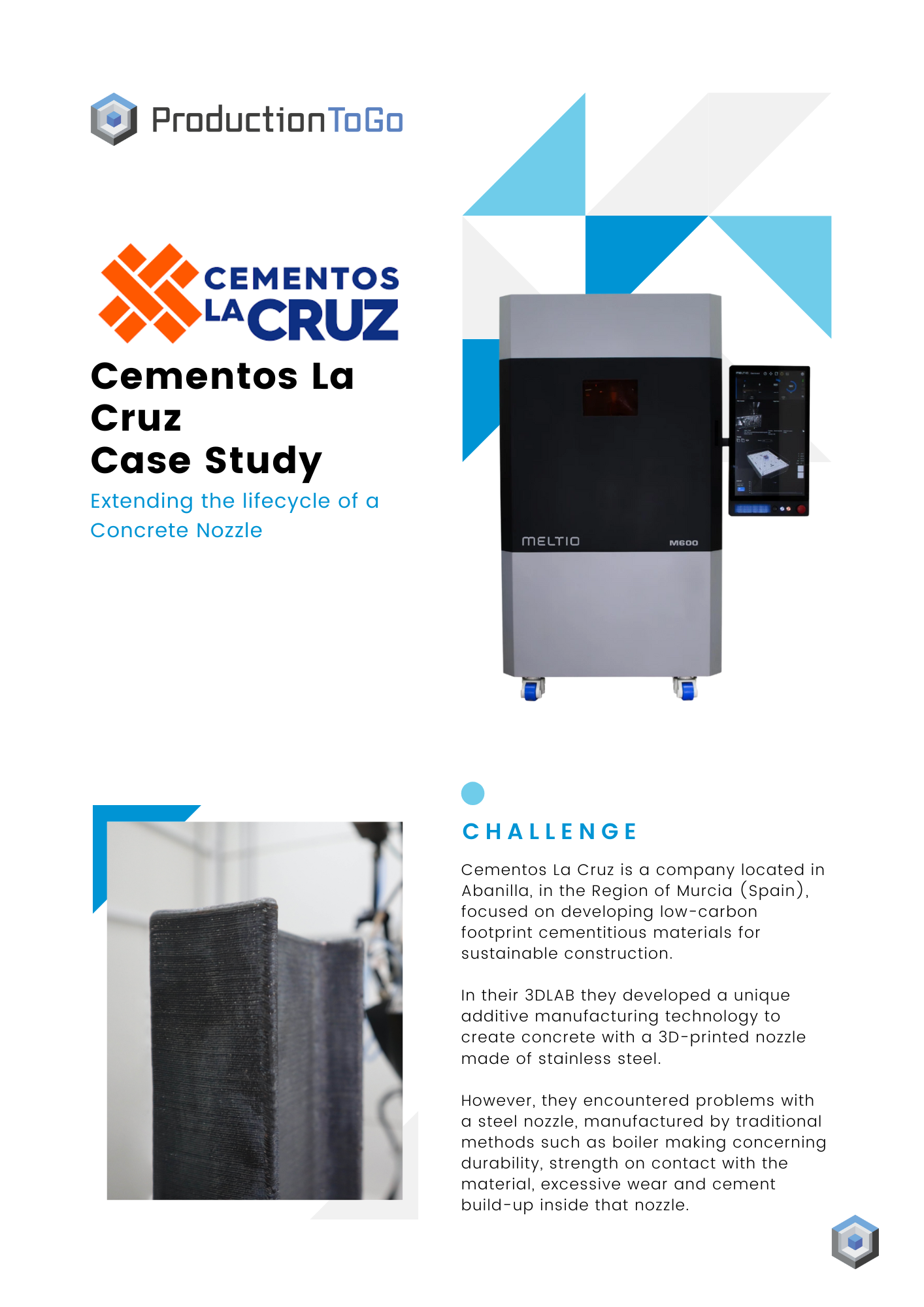

Cementos La Cruz is a company based in Abanilla in the Murcia region of Spain that specializes in the development of low-carbon cementitious materials for sustainable construction. At their 3DLAB, they developed a unique additive manufacturing technology to produce concrete with a 3D-printed stainless steel nozzle. However, a steel nozzle manufactured using conventional methods such as boilermaking encountered issues related to durability, strength in contact with the material, excessive wear and cement buildup inside the nozzle. Discover how Meltio was able to solve this problem in this use case!

Fill up the form below and we will send you the data sheet by e-mail.

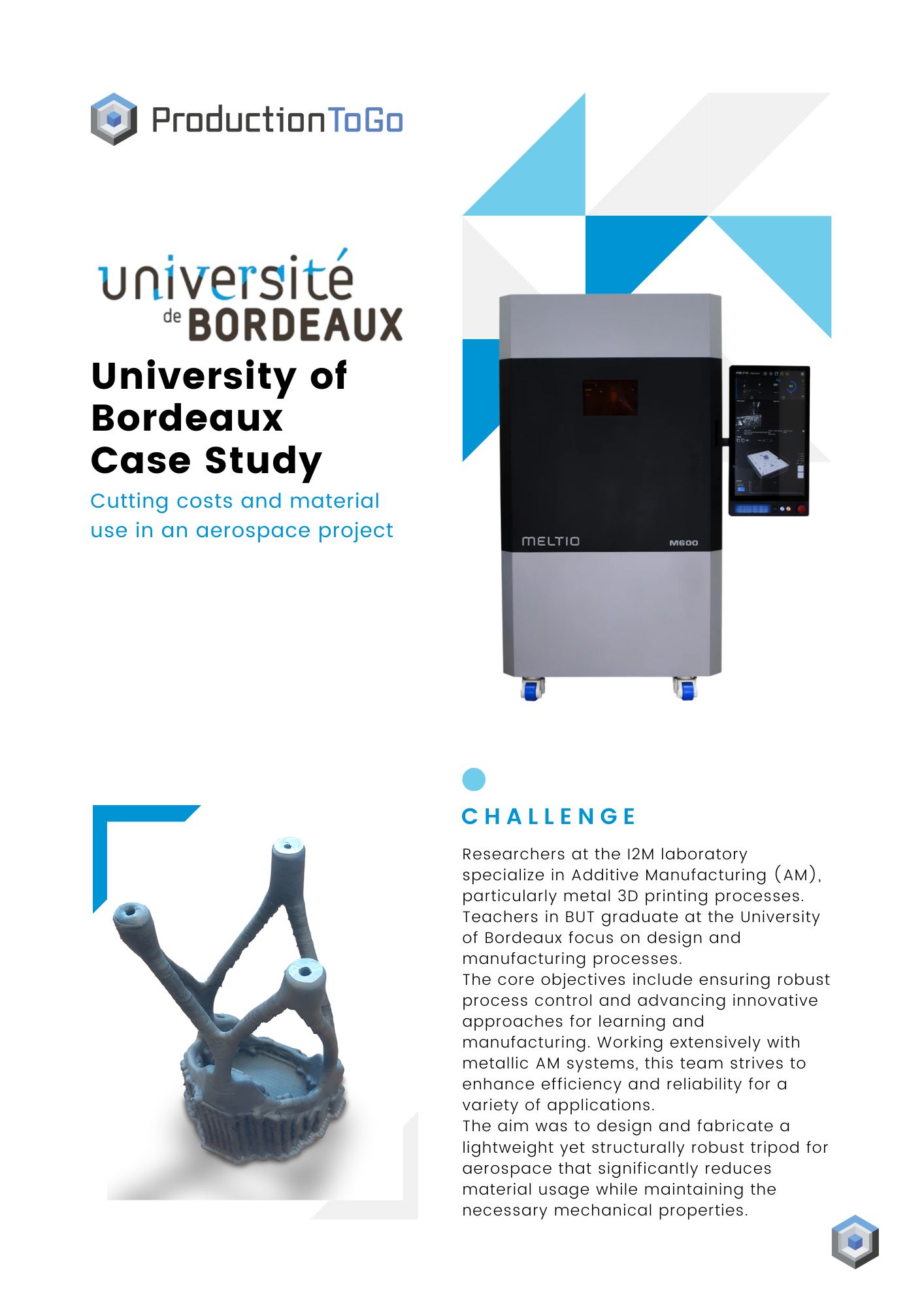

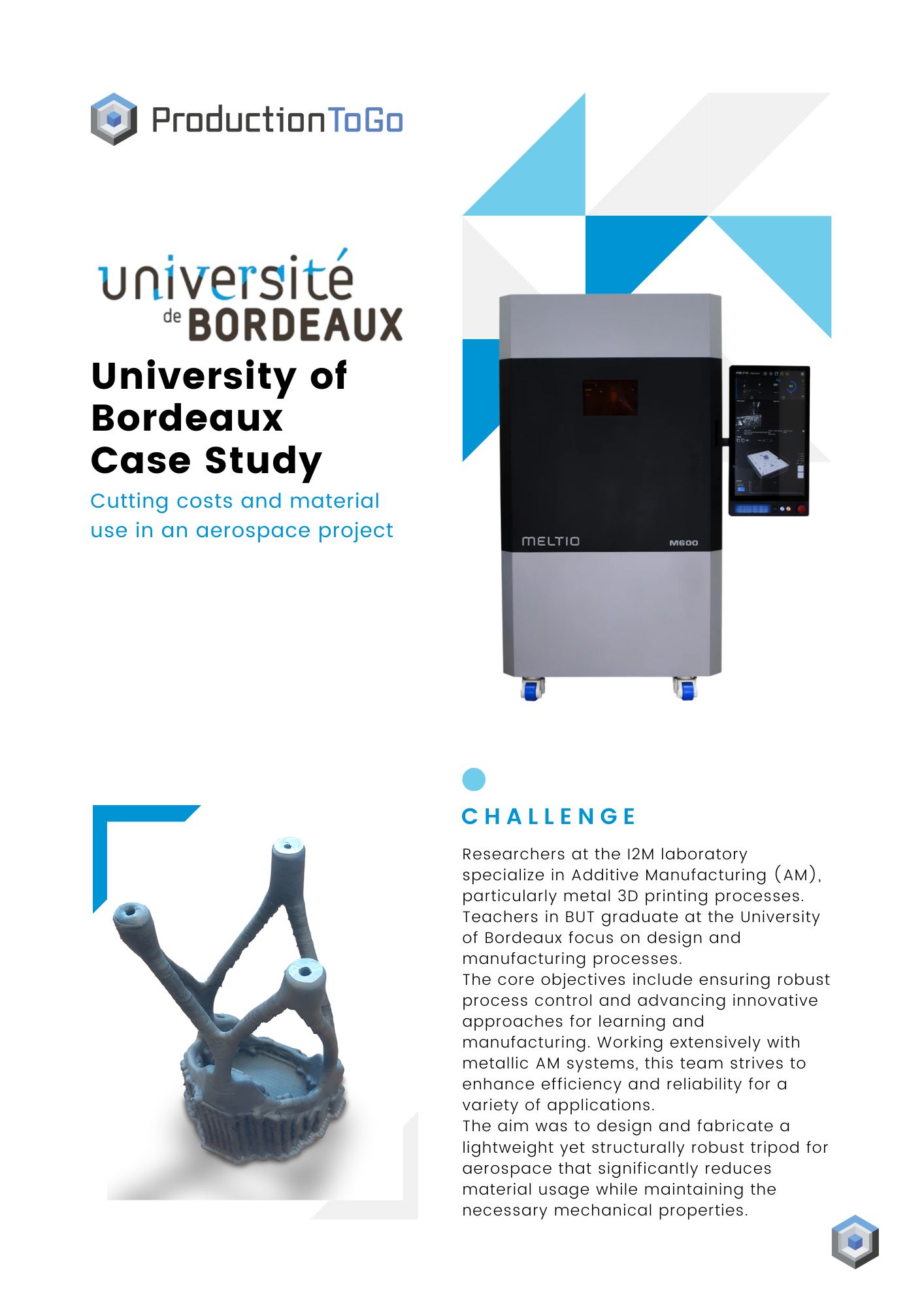

The researchers at the I2M laboratory specialise in additive manufacturing, particularly 3D metal printing processes. The teaching staff at BUT, who graduated from the University of Bordeaux, focus on design and manufacturing processes. Core objectives include ensuring robust process control and further developing innovative approaches to learning and manufacturing. The aim was to design and manufacture a lightweight yet structurally robust tripod for the aerospace industry that significantly reduces material consumption while maintaining the required mechanical properties.

Fill up the form below and we will send you the data sheet by e-mail.

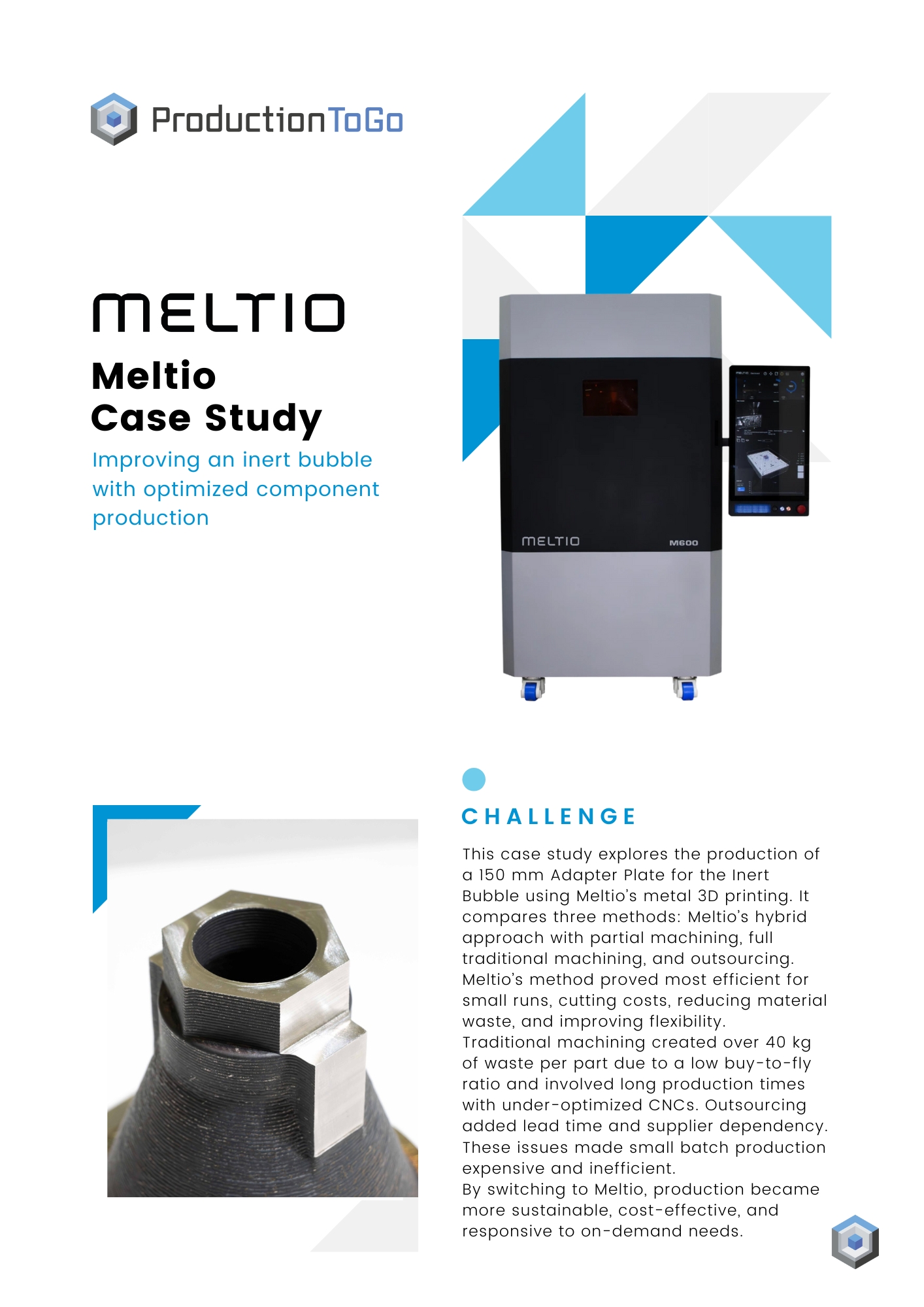

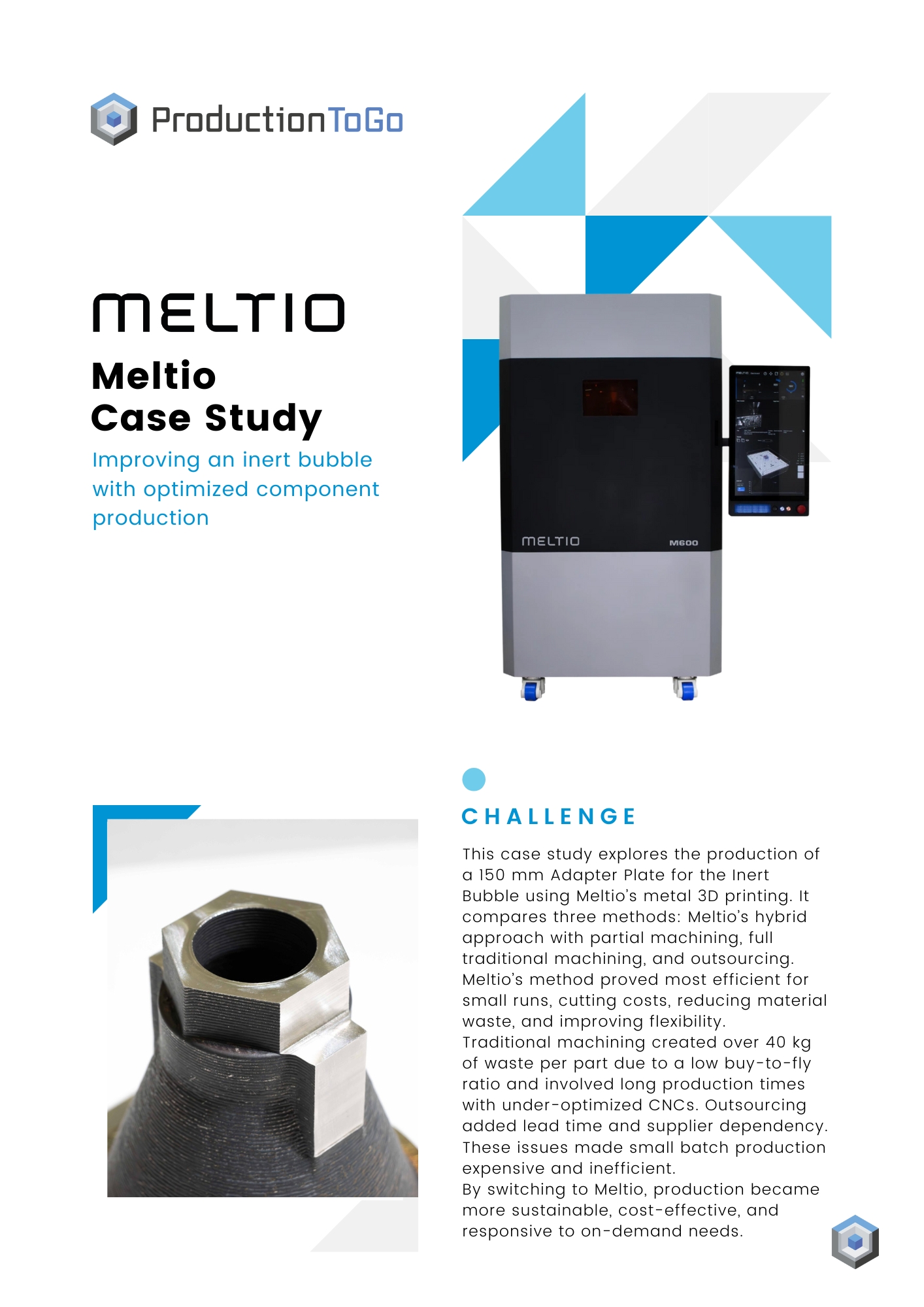

This case study looks at how a 150 mm adapter plate for the inert bubble was made more efficiently using Meltio’s metal 3D printing technology. Three methods were compared: 3D printing with some finishing work, fully traditional machining, and outsourcing. The results show that Meltio’s method saves money, uses less material, and gives more flexibility.

Fill up the form below and we will send you the data sheet by e-mail.

A customer from the automotive sector faced a major challenge: a component for a racing vehicle had to withstand extreme temperatures of over 800 °C – all within tight budget and very short delivery time. Together with the Meltio M600, ERM Fab&Test found a solution that not only met the technical requirements but was also faster, more cost-effective, and more precise than expected.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy