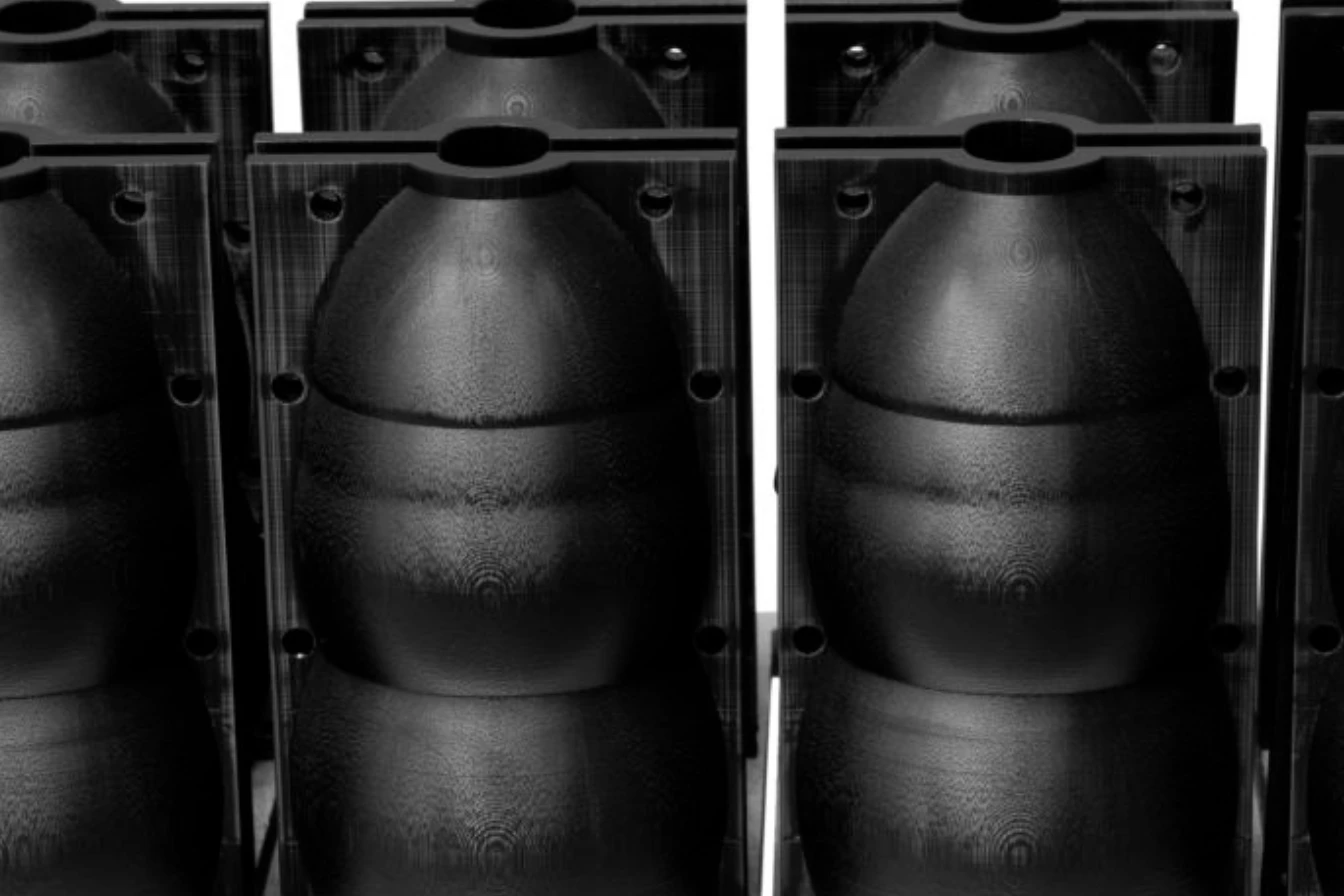

Evonik INFINAM® RG 3101 L

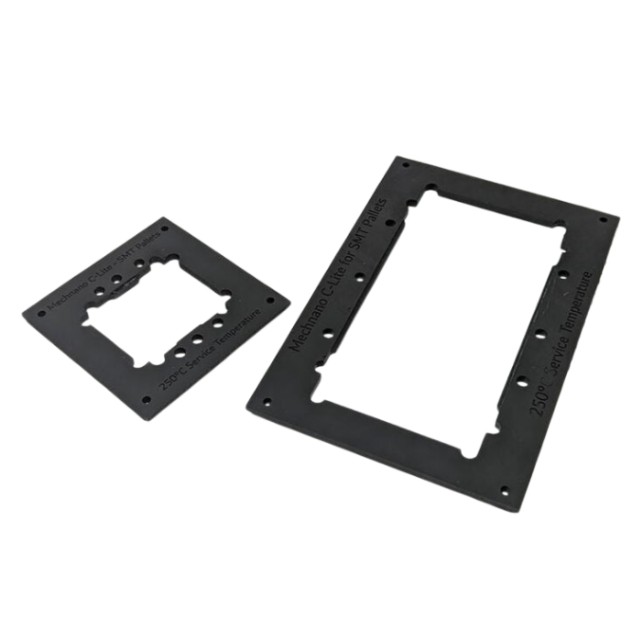

INFINAM® RG 3101 L resin is a black colored liquid photopolymer formulation, which is fast-curing and easy to process (1-part system). The fully cured material exhibits excellent thermomechanical properties (high impact strength combined with high temperature resistance).