Desktop Metal® AISI 316L / 1.4404 (Shop System™)

AISI 316L is an austenite and therefore non-magnetizable.

Thanks to its excellent ductility, corrosion resistance and weldability, this material is widely used regardless of the industry.

We offer 3D printing solutions that can process materials using Metal Binder Jetting Technology (MBJ) and Metal Fused Deposition Modeling Technology (MFDM).

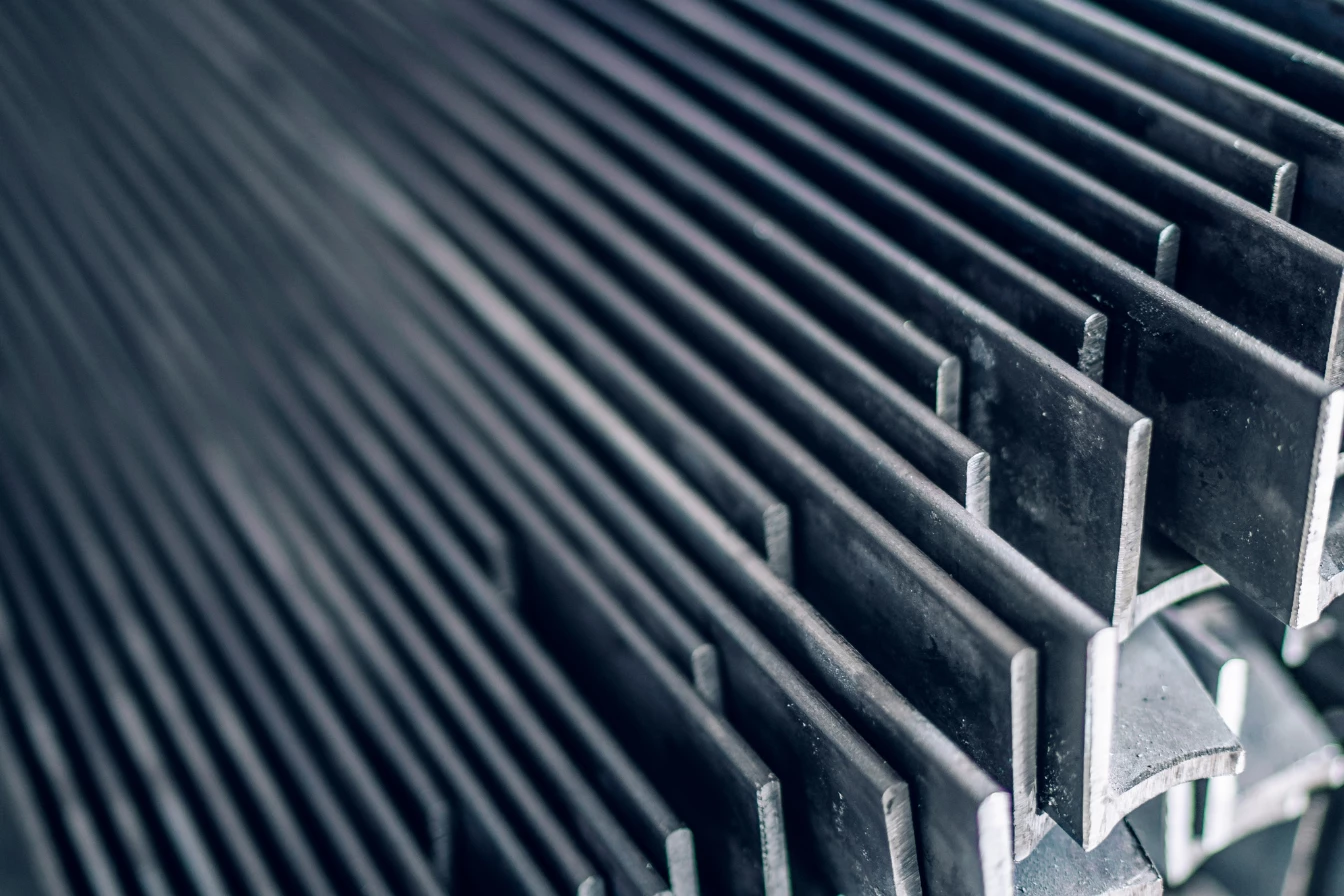

Metal Binder Jetting Technology (MBJ) is a technology in which the first step is to apply a binder to a bed of metal powder. This is followed by a phase of stabilization of the binder, desoldering and finally sintering of the parts, similar to MIM (Metal Injection Molding).

Metal Fused Deposition Modeling technology (MFDM), which uses metal powder or nearly full-metal filaments extruded through a reinforced or hardened steel extruder nozzle, is the workhorse of metal 3D printing. The plastic part of the filament (or binder) is removed in the post-processing to reveal a part that is up to 98% metal, although it can have relatively high porosity.

We offer you a large selection of metal powders and filaments for these two technologies. These materials cover a wide range of requirements, such as higher strength and hardness, and are often times more flexible than components made with a traditional process.

We can offer you many different materials, which you will find listed below.

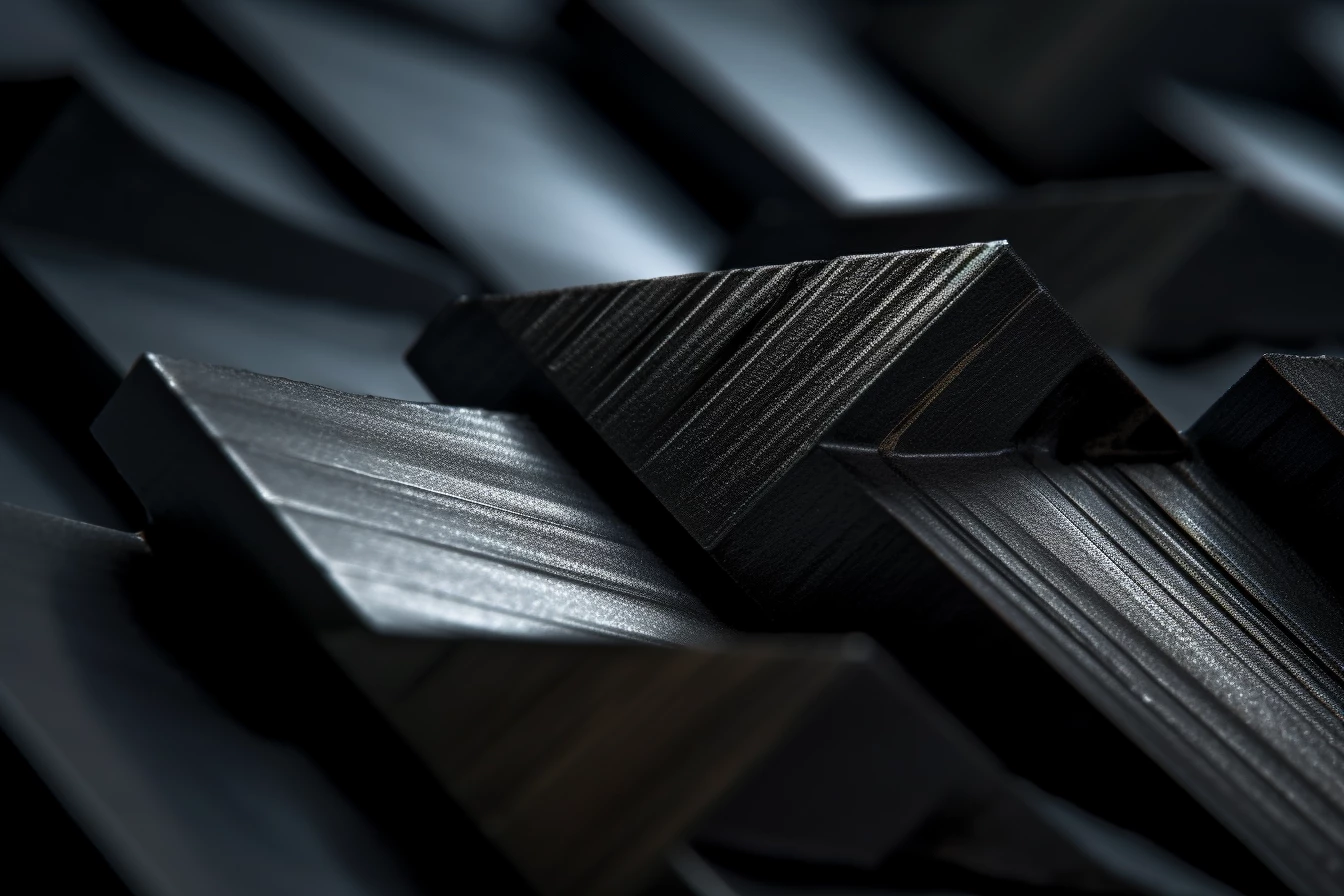

316L is a fully austenitic steel known for its corrosion resistance and excellent mechanical properties at extreme temperatures. It is ideal for applications in the most demanding industrial environments, including marine salt water, caustic cleaning agents in food processing and chemicals in pharmaceutical manufacturing.

17-4 PH is a martensitic and precipitation hardened stainless steel. It is known for its corrosion resistance and high strength and hardness, especially when heat treated. 17-4 can be heat treated to a wide range of hardness and toughness levels, allowing users to tailor the post-sintered alloy properties for a variety of applications.

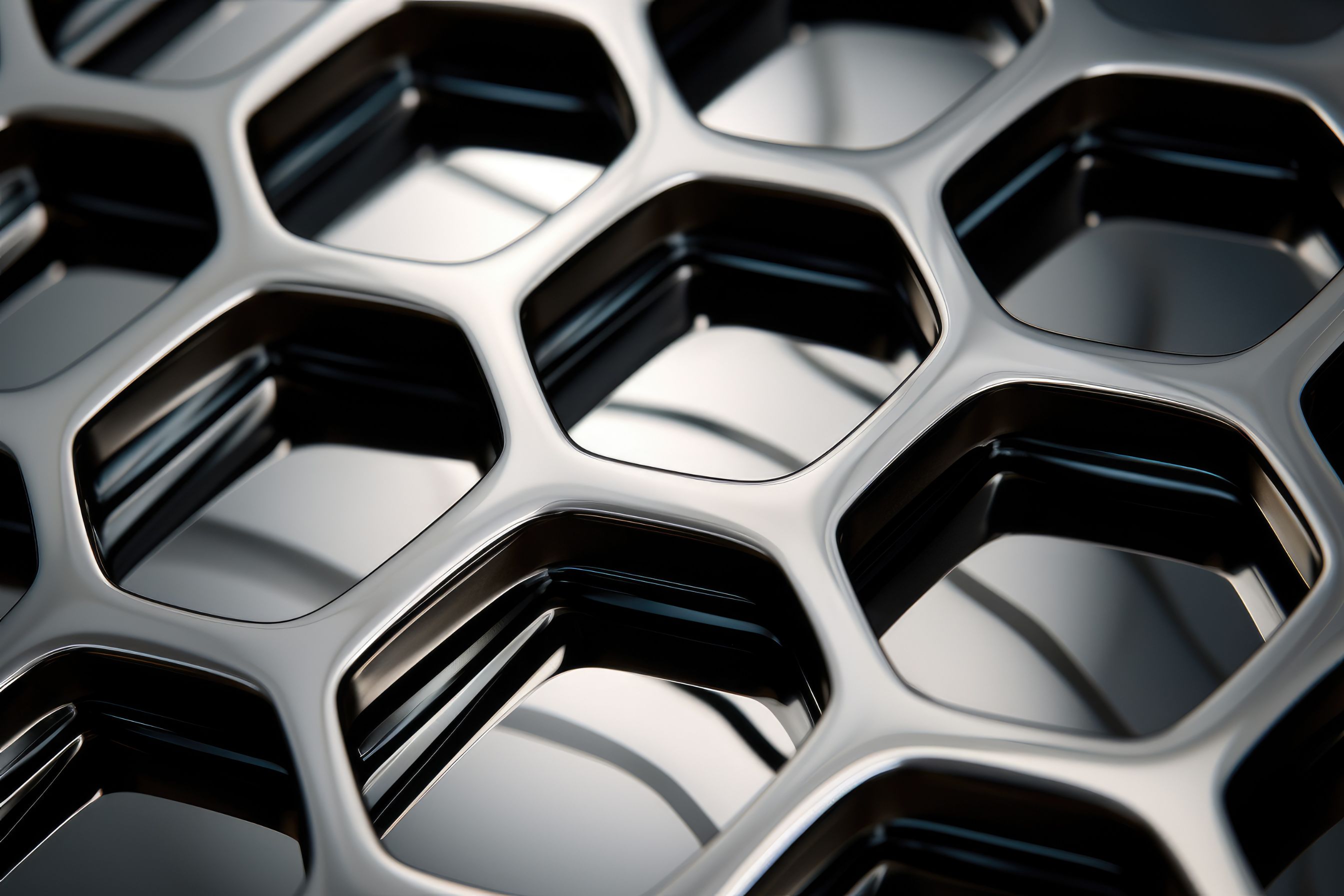

With its excellent thermal and electrical conductivity, copper is the ideal material for transferring heat or electricity. Because of this, it is used in virtually every electronic device, as well as many heat exchangers in the oil, gas, automotive, and consumer goods industries.

For cast items with thin walls and complex geometry, AlSi10Mg is a common casting alloy with good casting characteristics. Since it has good strength, hardness, and dynamic qualities, it is also utilised for parts that must withstand heavy loads. AlSi10Mg components are perfect for uses that call for a balance of good thermal performance and lightweight. If necessary, they can be machined, spark-eroded, welded, polished, micro-shot-peened, and coated.

This is not a problem! We are open to your wishes. We would be happy to check for you whether your desired material can be reliably processed on our printers. Simply contact us via our contact form. We are looking forward to it!