What does “flexible” stand for in 3D printing?

In the context of 3D printing, the term "flexible" refers to a material's capacity to bend, stretch, or deform under applied forces while maintaining structural integrity. Flexible filaments or resins in 3D printing enable the manufacture of items with qualities comparable to rubber, allowing for the production of components that can be deformed or compressed. This flexibility is especially useful in applications like wearable technology, medical gadgets, and flexible prototypes, where elasticity and adaptability are critical.

What are the levels of flexibility?

Flexible

Flexible materials have a high degree of flexibility that allows for significant bending and stretching. TPU (thermoplastic polyurethane) is a typical type of flexible 3D printing filament. Cell phone cases, shoe insoles and other products that require high flexibility are made from this type of material.

Highly Flexible or Rubbery

Highly flexible or rubber-like materials have a high degree of elasticity and closely resemble the qualities of rubber. These materials can withstand significant deformation, making them ideal for applications requiring a soft and rubbery texture. They are extensively utilized in the manufacture of flexible prototypes, gaskets, and shock-absorbing components.

Super Soft or Ultra-flexible

Super soft or ultra-flexible materials provide the greatest degree of flexibility in 3D printing. These materials are highly soft and malleable, and are frequently used to mimic the feel of human tissues or to create flexible and squeezable items. Medical models, soft robotics, and haptic feedback devices are some of the potential applications.

What are the benefits of 3D printing for flexible applications?

Customization and Design Freedom

Additive manufacturing enables the fabrication of complicated geometries and elaborate designs that can be customised for specific uses. This versatility allows for the creation of custom-fit components, assuring peak performance and functionality.

Rapid Prototyping and Iterative Development

3D printing makes rapid prototyping possible, allowing designers and engineers to swiftly iterate through many versions of flexible parts. This quicker development process makes it possible to test and refine designs at a lower cost. The capacity to make rapid design changes helps to accelerate product development cycles and innovation.

Diverse Applications Across Industries

3D printing for flexible parts has a wide range of applications in industries such as electronics, healthcare, automotive, and robotics. Wearables, soft robots, medical gadgets, and other products all benefit from flexible components. The versatility of 3D printing in producing parts with varied degrees of flexibility meets the diverse needs of industries seeking customised, ergonomic, and robust solutions.

What are the applications of flexible materials in 3D printing?

Automotive Applications

Flexible seals and gaskets: These components, which are frequently subjected to dynamic movements and vibrations, require materials that are both flexible and durable. Additive manufacturing enables the rapid prototyping and production of unique, complex-shaped seals for improved performance.

Interior components: Flexible materials are used to make interior components including dashboards, knobs, and grips. The ability to 3D print these components with different degrees of flexibility improves the overall comfort and attractiveness of automobile interiors.

Medical Devices and Prosthetics

Flexible prostheses: Materials such as TPU enable the production of limb prostheses that mimic natural movements and offer a more precise and customizable alternative. Customization ensures a precise fit and therefore improved mobility.

Flexible surgical models: Flexible 3D printing helps to create anatomical models that precisely reflect the qualities of human tissues. Surgeons employ these models for pre-operative planning and practice, particularly in procedures involving flexible and dynamic organs.

Consumer Goods

3D printed flexible products have a huge impact on the consumer goods market, providing novel options for personalised and adaptable products. This technology enables the production of custom-made, ergonomic and comfortable things such as footwear, apparel, and accessories that may be adjusted to specific preferences and body shapes. 3D printing enables the manufacturing of customized sporting and day-to-day items such as insoles, swimming gear, sports bands, gloves, protective gear, wearables and many more.

What materials do we recommend for flexible parts in 3D printing?

INFINAM® RG 7100 L from Evonik - Printed on the Nexa3D® XiP Pro

INFINAM® RG 7100 L was specially developed for DLP and mSLA printers and enables the production of parts with isotropic properties and low moisture absorption. Printed parts have fine features and smooth and glossy surfaces, making the new photopolymer ideal for sophisticated design visualizations.

INFINAM® RG 7100 L can also be used for applications such as drones, buckles or automotive parts that require high ductility combined with high impact strength. The printed parts can be machined and remain fracture resistant even when exposed to high forces.

The mechanical properties are comparable to those of an ABS material and the black coloured formulation can also be used on high throughput printer systems like the ultra-fast resin 3D printer, Nexa3D® XiP Pro. The unique LSPc® technology of Nexa3D® allows for the rapid manufacture of flexible parts with high resolution in a matter of hours.

XiP Pro

Have your components 3D printed now! Do you have any questions? Contact our experts!

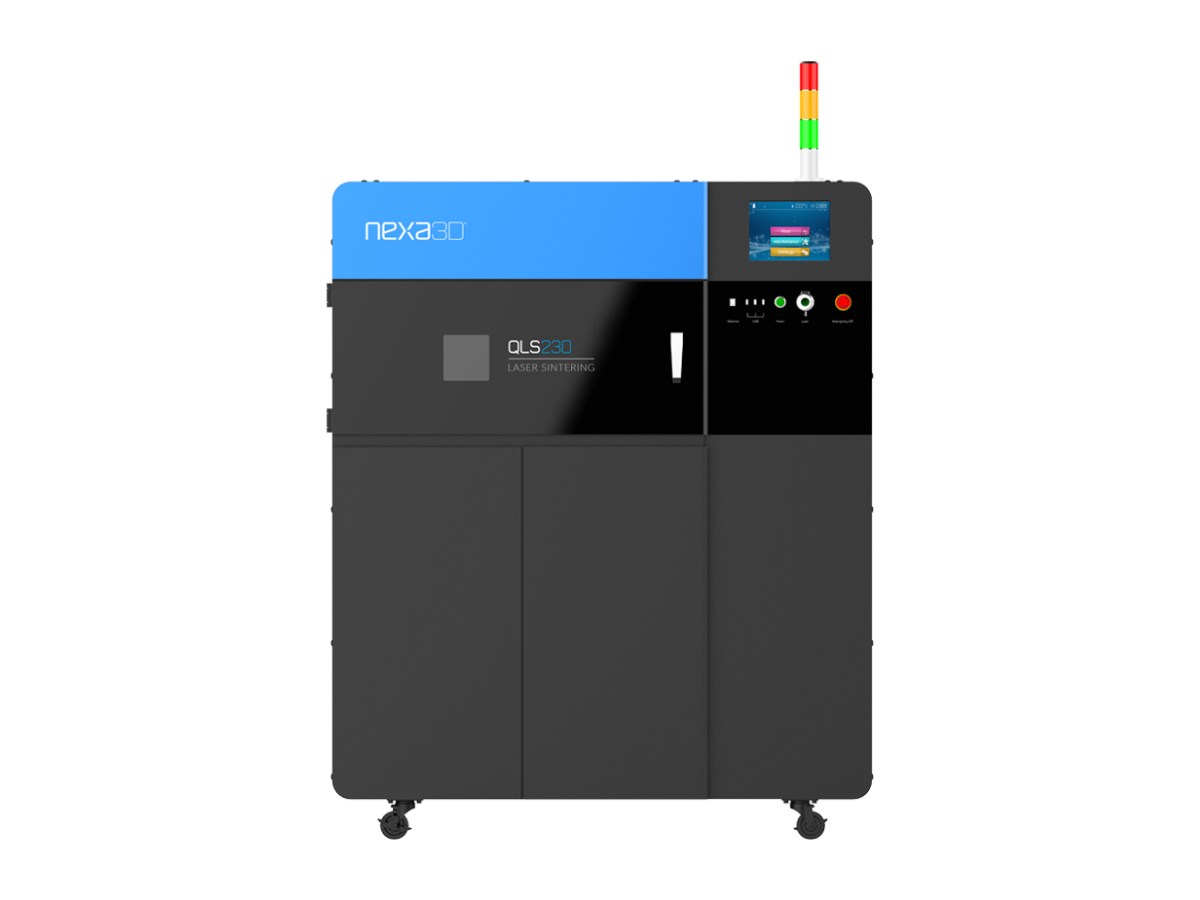

INFINAM® TPC 8008 P from Evonik - Printed on the Nexa3D® Powder Printers

Bring flexibility to your production with INFINAM® TPC 8008 P! This material from Evonik has breathtaking elasticity and flexibility and combines this with a high surface resolution and excellent resilience.

Thanks to its increased resistance to moisture and chemicals of all kinds, Evonik INFINAM® TPC 8008 P is suitable for use in outdoor applications as well as in industrial plants where chemicals are used.

A variety of printers, including the powder 3D printers of Nexa3D® such as the QLS 230, QLS 236, QLS 260 and the QLS 820 can print this material with precision without the use of supports, allowing you to design flexible and complicated structures.

QLS 820

QLS 260

QLS 236

QLS 230

Have your components 3D printed now! Do you have any questions? Contact our experts!

INFINAM® TPA 4006 P from Evonik - Printed on the Nexa3D® Powder Printers

With INFINAM® TPA 4006 P, Evonik is launching the ideal solution for applications that require components with rubber-like properties. These rubber-like properties are complemented by fantastic impact strength and rebound properties to create an all-rounder for many applications.

In addition to its mechanical properties, INFINAM® TPA 4006 P also shines with its appearance. It enables excellent surface resolution, giving even the smallest details the highest quality.

A variety of printers, including the powder 3D printers of Nexa3D® such as the QLS 230, QLS 236, QLS 260 and the QLS 820 can print this material with precision without the use of supports, allowing you to design flexible and complicated structures.

QLS 820

QLS 260

QLS 236

QLS 230

Have your components 3D printed now! Do you have any questions? Contact our experts!

FDM TPU 92A from Stratasys® - Printed on the Stratasys® F370

FDM TPU 92A is a durable thermoplastic polyurethane that combines flexibility and stretch with abrasion and tear resistance. 3D printing with FDM TPU 92A outperforms less ideal TPU 3D printing technologies and removes costly and time-consuming molding or casting procedures for producing elastomer products.

The long-lasting flexibility of FDM TPU 92A material makes it suitable for a wide range of applications, including flexible hoses, tubes, air ducts, and vibration dampeners.

Stratasys®'s industrial FDM 3D printers, such as the F370 from the F123 Series, provides dependable print results using the FDM TPU 92A to provide accurate, repeatable 3D printing suitable for the office, classroom, or factory floor.

Have your components 3D printed now! Do you have any questions? Contact our experts!

xFLEX402 black from Nexa3D® - Printed on the Nexa3D® XiP Pro

xFLEX402-Black is a single-component elastomer material with great elongation and durability, outstanding tensile strength, and high energy return that does not require thermal post-processing.

xFLEX402 black is manufactured by Henkel, branded for Nexa3D® 3D printers. The resin is a flexible material with a stiffer short 76A durometer that is ideal for functional prototypes of elastomeric components and manufacturing parts.

The XiP Pro printer from Nexa3D® is one of the ultra-fast resin 3D printers that are specifically made for the xFLEX402 black resin. The unique LSPc® technology of Nexa3D® allows for the rapid manufacture of flexible parts with high resolution in a matter of hours.

XiP Pro

Have your components 3D printed now! Do you have any questions? Contact our experts!

xFLEX475 from Nexa3D® - Printed on the Nexa3D® XiP Pro

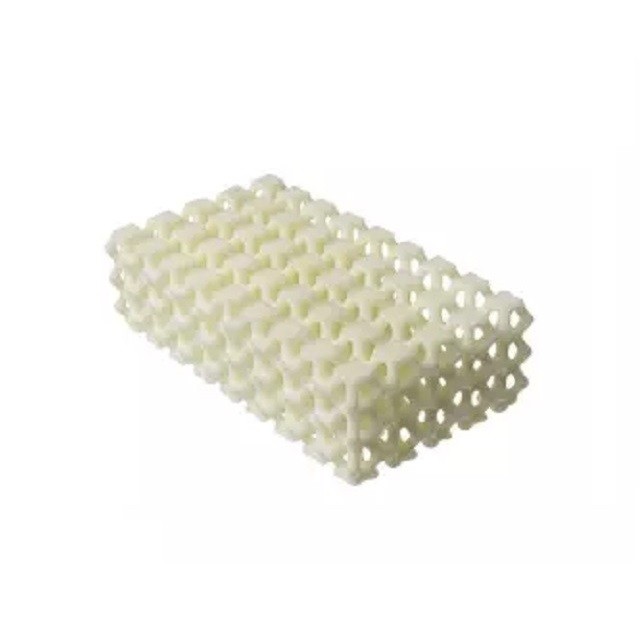

Nexa3D®'s xFLEX475 is an industrial-strength UV resin that cures into a soft, elastomeric substance. xFLEX475 is ideal for applications requiring resilience, snap back, rip resistance, and lattice constructions.

Henkel manufactures xFLEX475, which is branded for Nexa3D® 3D printers. This single-component resin is easy to print, making it an excellent choice for elastomeric applications.

The XiP Pro printer from Nexa3D® is one of the ultra-fast resin 3D printers that are specifically made for the xFLEX475 resin. The unique LSPc® technology of Nexa3D® allows for the rapid manufacture of flexible parts with high resolution in a matter of hours.

XiP Pro

Nexa3D® xFLEX475-Black

Nexa3D® xFLEX475 white

LOCTITE 3D IND475 A60 High Rebound